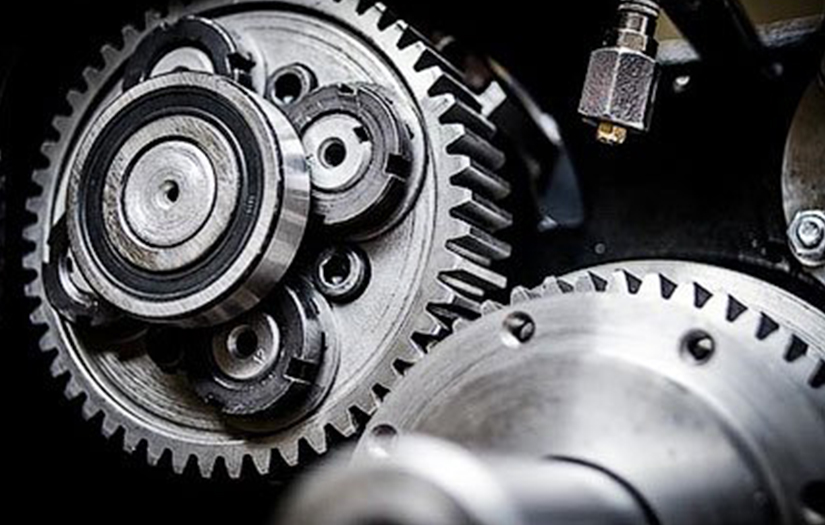

EnCata is a one-stop full-cycle product development hub which accommodates specialists in mechanical design, electronics design, low-level software development, computer simulations, industrial design, production preparation process. The expertise of the team steers the product from ideation to mass production. We have our own pilot production facility.

The company was founded in 2016 on the basis of a company for the development and production of industrial filtration ventilation equipment.

For the time being, our team involves 60+ engineers.

EnCata’s portfolio includes 350+ successful projects – from wearable devices to factory automation solutions.

Focus Areas

Service Focus

- Engineering Services

- IoT Development

- Robotic Process Automation

- Software Development

- Other Services

Client Focus

- Small Business

- Medium Business

Industry Focus

- Manufacturing

- Enterprise

- Productivity

EnCata Executive Interview

We know we are a unique company for hardware development, since we have all the design, engineering and prototype manufacturing in-house. With this interview I wanted to highlight this uniqueness and reach out to those looking for professional and affordable engineering services such as EnCata offers.

We would like to continue working with GF and kindly ask our customers to leave reviews on the platform. We also keen on the be recognised as a unique player in IoT/hardware/deeptech development which also has software development capabilities (which rare if not unseen).

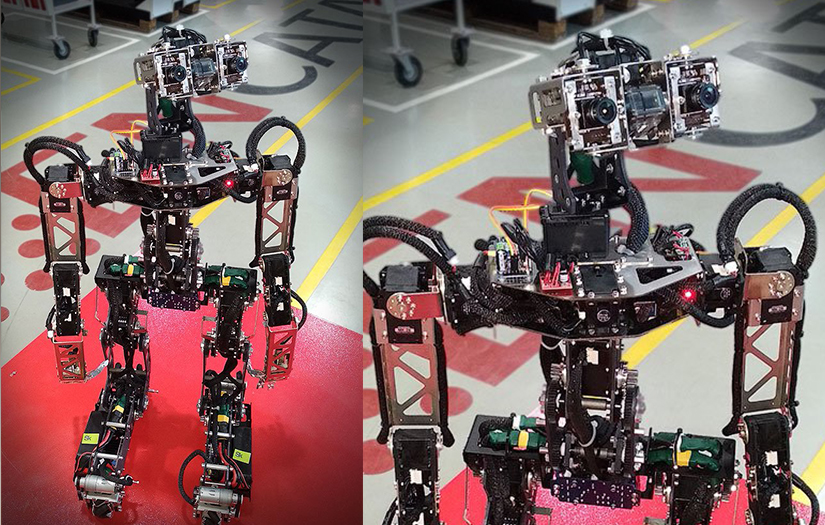

EnCata works with startups, SMEs and corporate sector in effort of bulding software, IoT and physical products for a range of verticals. EnCata employs NASA’s Technology Readiness Level (TRL) methodology to manage R&D and new product development lifecycle. Our one-stop-shop new product development service and expertise in sciences enables EnCata to tackle multidisciplinary projects, perform technology transfer, R&D, early stage product development and deliver bespoke designs and engineering solutions in hardware & software. We employ thorough LEAN development and manufacturing process, following Agile methodology.

EnCata is the independent design house, and the entire business model is based on delivering premium R&D, design and industrial prototyping services to our clients. Importantly, when working with our clients we sign a contract where all the intellectual property to be generated during the R&D and engineering development belongs to the customer.

Starting from 2012 BDC was involved in industrial IoT and automation projects and some large R&D projects were launched in IC design/power electronics and industrial IoT. So in 2014/2015 we decided to expand our operations and started offering engineering, R&D and new product development services and founded EnCata (Engineering Catalyst). Soon we realized that we want to create a holistic ecosystem for IoT, hardware and tough-tech startups, as the mission of EnCata is to “catalyse” R&D and hardware product development process and help with expertise, advice and the network. In the past 5 years in EnCata we worked with over 100 various startups (domestic and international) engaged in IoT, biotech, medtech, M-IoT, medical devices, robotics, aerospace, materials/nanotech, electric transport and deeptech.

Understanding the startups/product lifecycle we expanded our design and manufacturing facilities and opened a brand new fablab MakeIT Center, where startups can rent the equipment and office space and build their POC and advances prototypes themselves, renting advanced CNC machinery (pay per minute of use). In 2018 we have become the private technopark adding institution capacity to the hardware/deeptech ecosystem of EnCata.

With that said, we must highlight our competitive pricing (compared to the Bay Area or East coast): since we are based in E. Europe, we can provide our premium services at least at 1/3 of the price compared to domestic design consultancies.

Aside from this, EnCata offers a whole hardware ecosystem where startups can move quickly and established companies can accelerate their R&D from the very early stages and new product development programs. All this unparalleled rapidness is due to our LEAN and standardized development and manufacturing process.

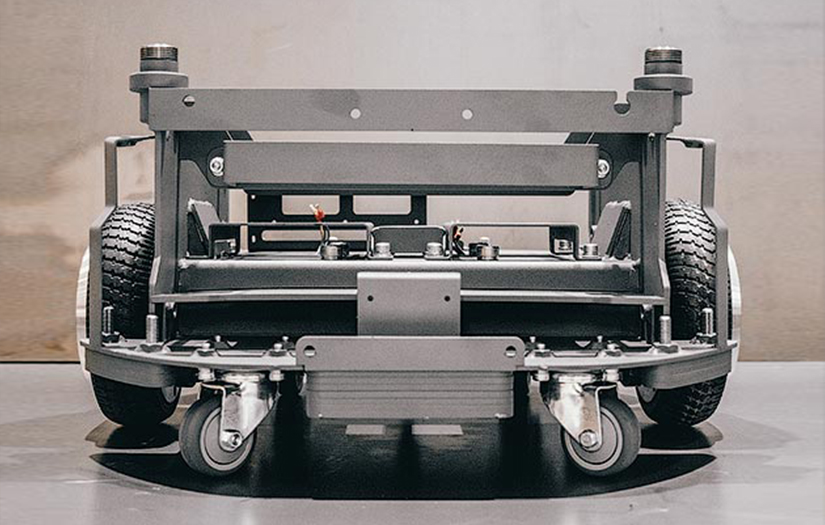

• Robotics

• Electric transport

• Deeptech & sciences

• Aerospace

• Consumer and wearables

• Advanced manufacturing and industrial automation

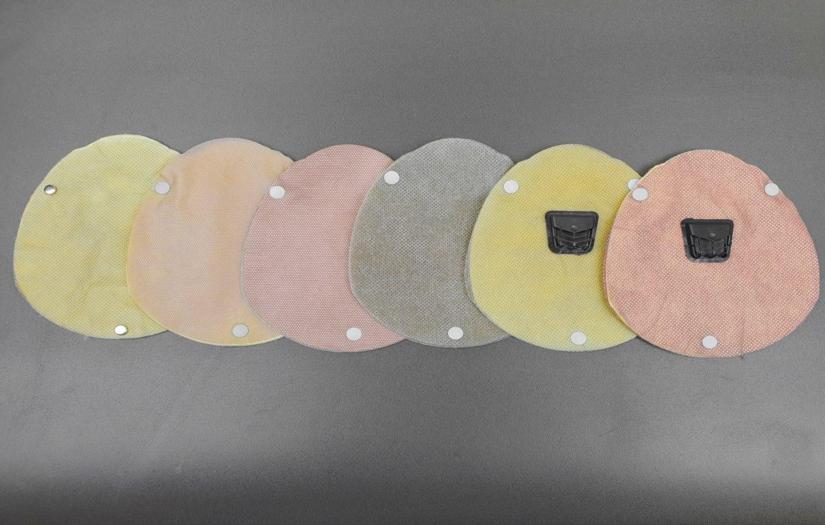

• Air purification / filtration and PPE

• Construction

We always start project from the discovery phase. Running discovery phase with EnCata allows one to develop a robust estimation for the project and the SOW and/or SRS (software requirements specification. The discovery lasts somewhere between 2 and 8 weeks and it allows our clients to do derisking of their project and carefully plan their budget and timelines.

The discovery phase costs from 5 to 10% of the total project cost.

Discovery phase is typically run by the technical / business analysts together with senior-level engineers (architects). And in some cases it allows to save up to 50% on the future development and implementation.

Once project proceeds into development, project milestones are monitored with certain agility achieved with 2-3 week sprints and short retrospectives at the end of each sprit. This applies to both hardware and software projects.

In IoT project a lot more work done on the back end and with the cloud. While mobile and web development projects can be equal in front vs backend efforts.

What concerns embedded systems, firmware and APIs – it is usually whole “sort of back-end” development, unless a GUI exists.

In hardware it is a selection of technologies, such as

• STM 32, NXP chips, Nordic chips, Texas Instruments (TI), 8/16/32 bit MCU, PID controllers, PLC / HMI.

• Wireless systems: Bluetooth® (BT) & LBE, Wi-Fi/WLAN (802.11), RFID, NFC

• LoRa WAN, Z-Wawe, ZigBee protocols. Cellular: 2G, 3G, 4G, GSM, GPRS; GPS / Beidou / GLONASS

• NB-IoT, LTE Cat-M; Interfaces: USB, SPI/SSP, I2C, LVDS, RS232/485, SD/SDHC/MMC, Ethernet, PoE, 1-Wire, CAN, I2S, AC97;

Some fixed price contracts take place, but they fit only small projects, or projects with detailed plan, strict delivery dates and very well defined requirements.

Same applies for hardware projects with the difference that there are components and materials to be procured; and machine time (especially CNC machinery) billed separately from engineering hours.

With respect to manufacturing and prototyping we can also take small projects and charge on a T+M basis, providing just a quick ball-park estimation prior to the start.

EnCata Clients & Portfolios

.jpg)

.jpg)

.jpg)

EnCata Reviews

- All Services

- Engineering Services

- Other Services

- Relevance

- Most Recent

- Rating: high to low

- Rating: low to high

Mechanical Development of Large Scale Industrial IOT Sensor that Withstands Harsh Environment

Review Summary

On this most recent project, we developed a large and complex IOT sensor assembly that is used in a harsh environment. We collaborated with EnCata entirely remotely. Although most of their engineers don't speak English fluently, their project managers do. We were able to rapidly brainstorm and evaluate different design concepts during the initial exploration phase. We chose two fundamentally different approaches and detailed them sufficiently to quote with potential contract manufacturers. We then selected a final configuration that we are now taking to production.

What was the project name that you have worked with EnCata?

Next Generation IOT Sensor Assembly

What service was provided as part of the project?

Engineering Services

Describe your project in brief

We worked together with EnCata to develop the mechanical design of a complex industrial sensor that is used in a harsh environment. EnCata designed the product from concept through production.

What is it about the company that you appreciate the most?

EnCata's designs receive limited DFM feedback from manufacturers. Encata's engineers have extensive fabrication process knowledge.

EnCata's value is hard to beat. Not only are their rates relatively low, but they are really fast at what they do.

The teams are always very responsive to our feedback. They are always pleasant to work with.

What was it about the company that you didn't like which they should do better?

Shipping prototypes to and from EnCata can be a little cumbersome, but they easily make up for that with the speed of the rest of their services.

Fabrication of a large electromechanical appliance.

Review Summary

The team at EnCata is skilled across the entire manufacturing spectrum, including electronic design, mechanical design, simulation, programming, DFM, and so forth. Their manufacturing capabilities are also broad rather than specialized, which is what you need for prototyping.

Cost-wise they are competitive with other locations, but you get what you pay for, in the sense that you will face some challenges. Travelling to Minsk is not as easy as to other locations and there are challenges (a visa in my case), but mostly the language, since English is not widely spoken. To me this was the biggest challenge. Also, since most parts must be imported, there is also a time, cost, and permit challenge here, since it takes time, money, and in some cases permits, to import components.

One of their best advantages is that they are committed to the project. They will get out of their way, every time, to support your project. I can honestly say they are really great. They really want to see you succeed and also want to succeed themselves. This will depend also on how committed you are to the project. One should not expect a project to progress fast while talking to them in remote. I think you really need to be on the ground in Minsk, overseeing things, and pushing the project. At least this was my experience. They are also quite accommodating and understanding, since I am not an easy person to work with – since I am very demanding – but they still put up with me, which speaks a lot for their patience (thank you Vadim! – and sorry for the pressure at times!)

Some manufacturing costs for prototyping can be a bit expensive there, e.g. milling, which I mitigated with off-shore milling services (China).

They are also a nice bunch of guys and girls to hang out with. They will show you their city, which is very lovely, and make you feel very welcome. They basically allow you into their house, which speaks a lot about their hospitality! I think I may have made some friends there too!

So, overall, I think my decision to work with EnCata was correct, and trust me, I did a ton of research, so you are benefiting my from work 😉

I wish to have another opportunity to work with them again.

Francesco Lo Conte

Piston Vault - https://pistonvault.com/

What service was provided as part of the project?

Engineering Services

Really happy with the engagment with Encata

Review Summary

They are professional, quick, honest and respected the timelines we set finishing the project on time and budget. Very helpful in further conversations, I do look forward to doing more business with them.

What service was provided as part of the project?

IT Services, Engineering Services

What is it about the company that you appreciate the most?

Skills, professionalism, honesty

What was it about the company that you didn't like which they should do better?

Nothing I can think of right now

My experiance with encata

Review Summary

What service was provided as part of the project?

Other Services

What is it about the company that you appreciate the most?

working environment

Great team.

Review Summary

What service was provided as part of the project?

Software Development, Engineering Services

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(2).jpg)

.jpg)