Write a Review

Unclaimed Profile

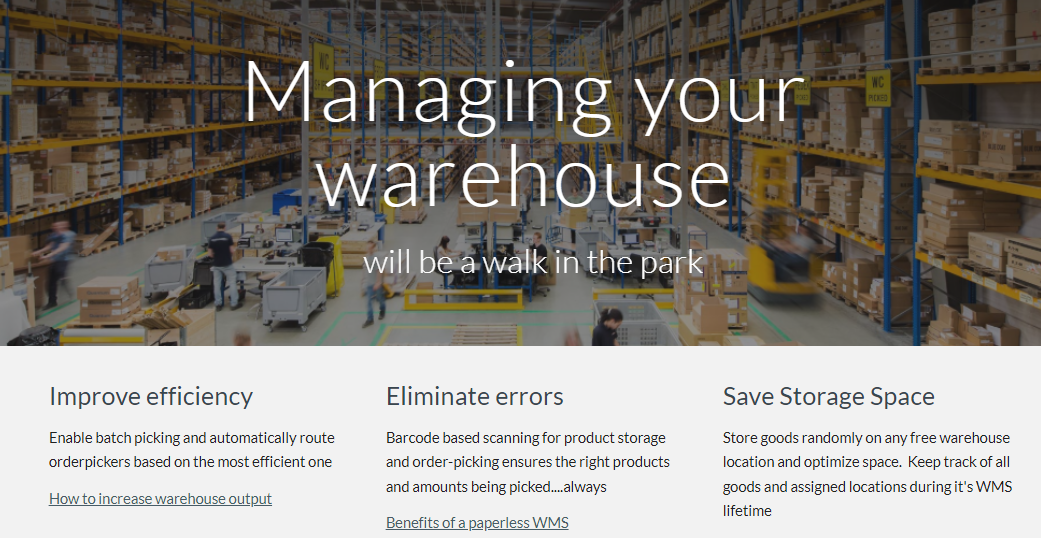

Clougistic is the best, most reliable, low-cost warehouse management SaaS solution for Magento. Implemented in just a few days instead of months. Every stock movement is tracked by Clougistic. It answers questions like, who supplied the current stock, did it move around in my warehouse and where can I find stock from a certain delivery. Paperless: eliminate paper and printing costs, boost warehouse output and increase accuracy to more than 99% with electronic inventory and barcode scanning. Clougistic guides warehouse employees through all processes, from receiving goods to shipping orders.

- Logistics-supply-chain

- Retail

- English

Screenshot & Video

LICENSING & DEPLOYMENT

- Open Source

- Cloud Hosted

- Web-based

- iPhone/iPad

- Android

- Windows

- Mac

- Linux

SUPPORT

- Phone

- 24x7 Support

Training

- In-person

Knowledge Base

- Help Guides

- Video Guides

- Blogs

Clougistic Core Features

- Accounting

- Alerts/Notifications

- Inventory Control

- Inventory Optimization

- Mobile Access

- Multi-Channel Sales

- Order Fulfillment

- Order Management

- Purchasing

- Reporting/Analytics

- Shipping

- 3PL Management

- Barcoding / RFID

- Category Customization

- Inventory Management

- Multi-Location

- Returns Management

- Shipping Management

- Stock Management

- Tracking

Clougistic Pricing

Pricing Type

-

Flat Rate

Preferred Currency

-

USD ($)

Free Version

-

No

Payment Frequency

-

Monthly Payment

-

Quote Based

Clougistic Reviews

Wally Kim

Posted on Nov 25, 2022

Clougistic is a fully featured warehouse management solution that integrates seamlessly with magneto.

Review Summary

It works great for my business. I was looking for something for warehouse management and this works perfectly. Easy to add and remove inventory easily. This warehouse solution is super easy and useful. It is important for me to do easy work and save time. Always looking forward to their future software updates.

Which features have you used in Clougistic?

Warehouse Management Software , Logistics Software

How long have you used Clougistic?

8 Months

How frequently you use Clougistic?

Daily

What do you like the most about Clougistic?

Easy to learn, and very fast.

Simple to use and quite detailed.

Pretty quick learning curve.

What do you like the least about Clougistic?

The user-Interface is good but needs some improvement. I hope they will resolve this issue.

This profile is not claimed

Do you own or represent this business? Enter your business email to claim your GoodFirms profile.