Rabio

budgeting cost control

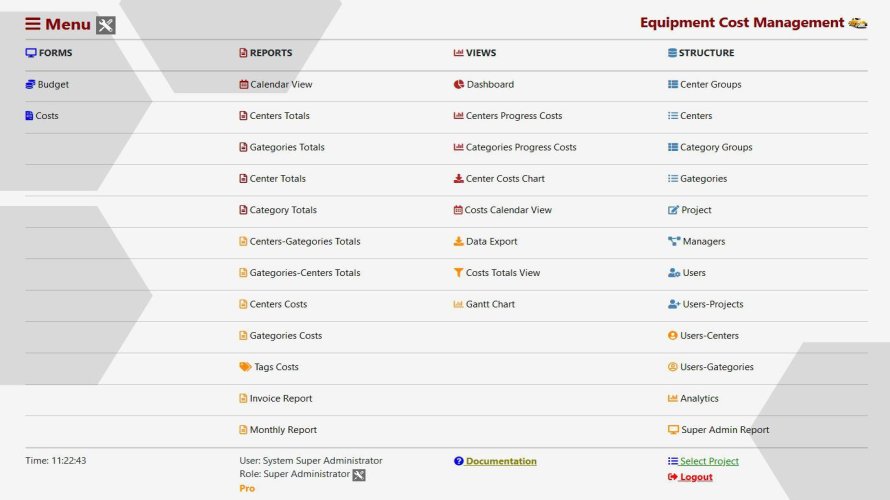

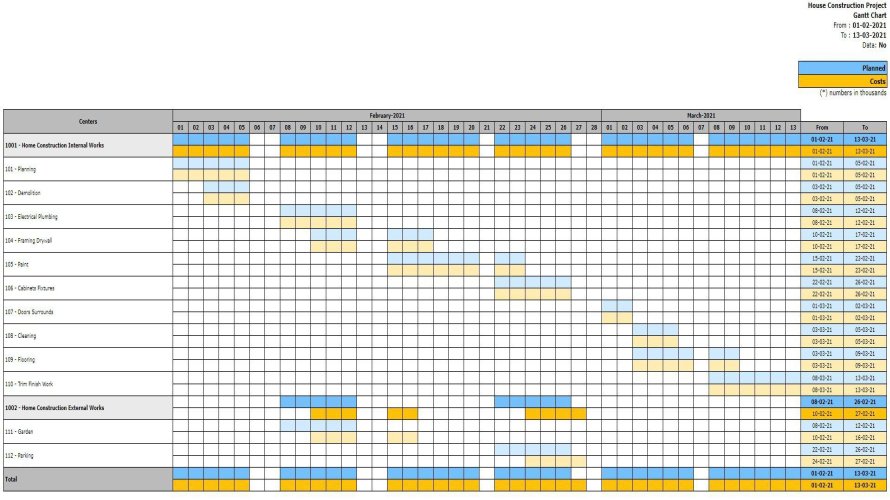

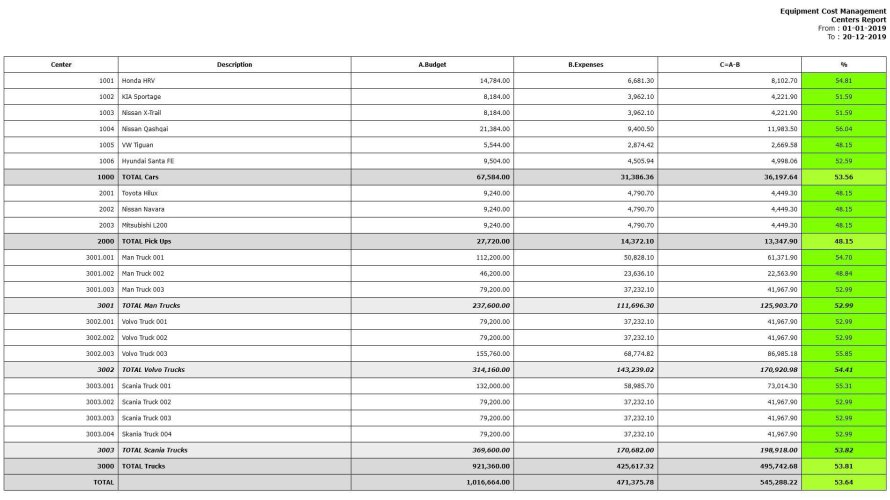

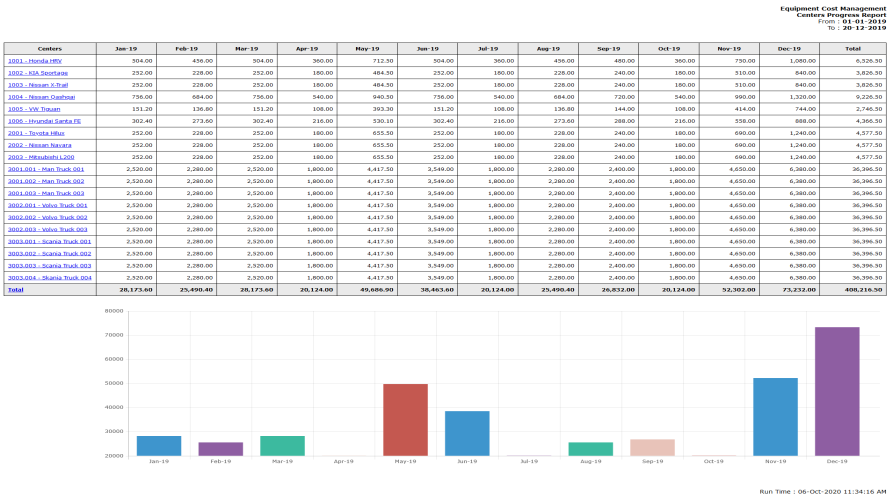

Rapid Business Information Organizer is an open-source budgeting software designed to organize projects and control their financial activities like budget, costs, earned value, forecast, projection, etc.

Licensing & Deployment

-

Cloud Hosted

-

On Premises

-

Web-based

Knowledge Base

-

Help Guides

-

Video Guides

-

Blogs

Media

Rabio Core Features

Focus of Budgeting Feature

- Financial Planning

- Forecasting

- Scenario Planning

Rabio Pricing

Pricing Type

-

Free

Payment Frequency

-

Free