A supply chain is the fulcrum of a business - the hinge around which operations rotate, especially manufacturing and production-oriented organizations. The constituents of a supply chain are diverse - individuals, organizations, and resources (technologies) - all of which assist in the manufacture, and sale of end products.

Having control of this important sector is what organizations have long sought to do. From Kanban Cards to the more recent just-in-time manufacturing and procurement - supply chain management grew leaps and bounds throughout the 20th century.

However, absolute control over the supply chain - especially aspects such as vendor management, customer serviceability, and inventory management - continued to evade businesses. It is these aspects that the more recent, 21st-century solution supply chain management software seeks to address.

This blog on supply chain management software establishes the advantages, essential features, and different free and open source supply chain management software to help you make the right call on what software fits your business needs.

So, what are you waiting for?! Read on below to begin your journey into supply chain management!

What is Supply Chain Management?

Considered the most critical operations management component, supply chain management includes all processes that create goods - transforming them from raw materials to finished products for markets. SCM’s primary goal is to ensure high efficiency in the entire chain or ‘flow of goods’ - so that organizations can reduce costs and wastage, deploy resources (shipping, storage, labor) effectively, and maintain quality leadership of the goods produced.

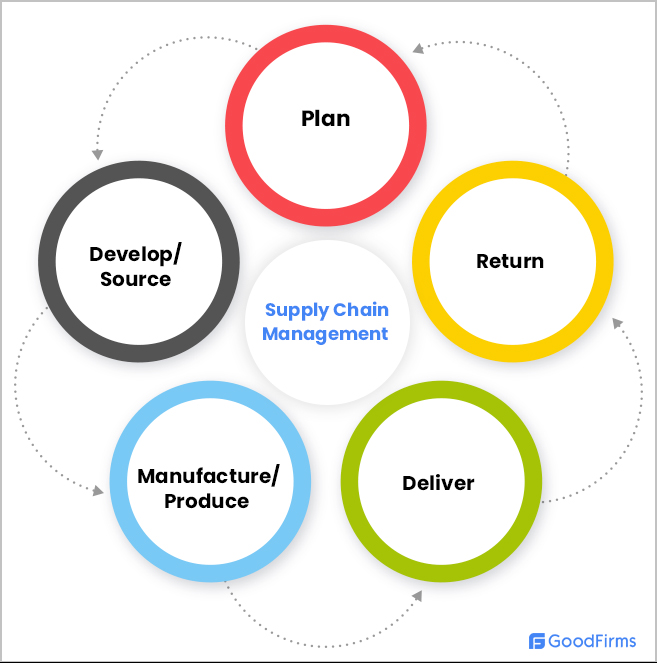

What does supply chain management involve?

Well, the following tasks best explain the crux of supply chain management:

- Planning - In this stage, companies decide how a product impacts the market. Here, supply chain management looks at ways to improve resource deployment and raw material acquisition.

- Development - This stage involves tie-ups with reliable suppliers to ensure the progressive supply of raw materials - quickly and cost-effectively. Inventory management, shipping, delivery, and payment are factors under consideration.

- Manufacture - This part of the supply chain management process is concerned with converting raw goods into finished products. Testing, packaging, scheduling, and manufacturing are completed in time to get exceptional quality products to customers.

- Delivery - Organisations must deliver products to consumers without any friction. Streamlining functions such as warehouse logistics, customer invoicing, and payment collections are necessary to meet end goals.

- Returns - This stage deals with responding to customer queries and ensuring damaged products are picked up hassle-free for the buyer. Returns and replacements involve massive coordination between logistics and supply chain management processes. It involves a flexible system to accept damaged, excess goods from customers and send them fresh pieces while keeping records.

- Monitor - This stage involves analyzing the entire supply chain processes to prevent stockouts, assure stakeholders’ compliance adherence, and flawless delivery.

Supply chain management brings excellent value to the customer and gets businesses that implement this function efficiently for a sharp-edged competitive advantage.

Evolution of Supply Chain Management

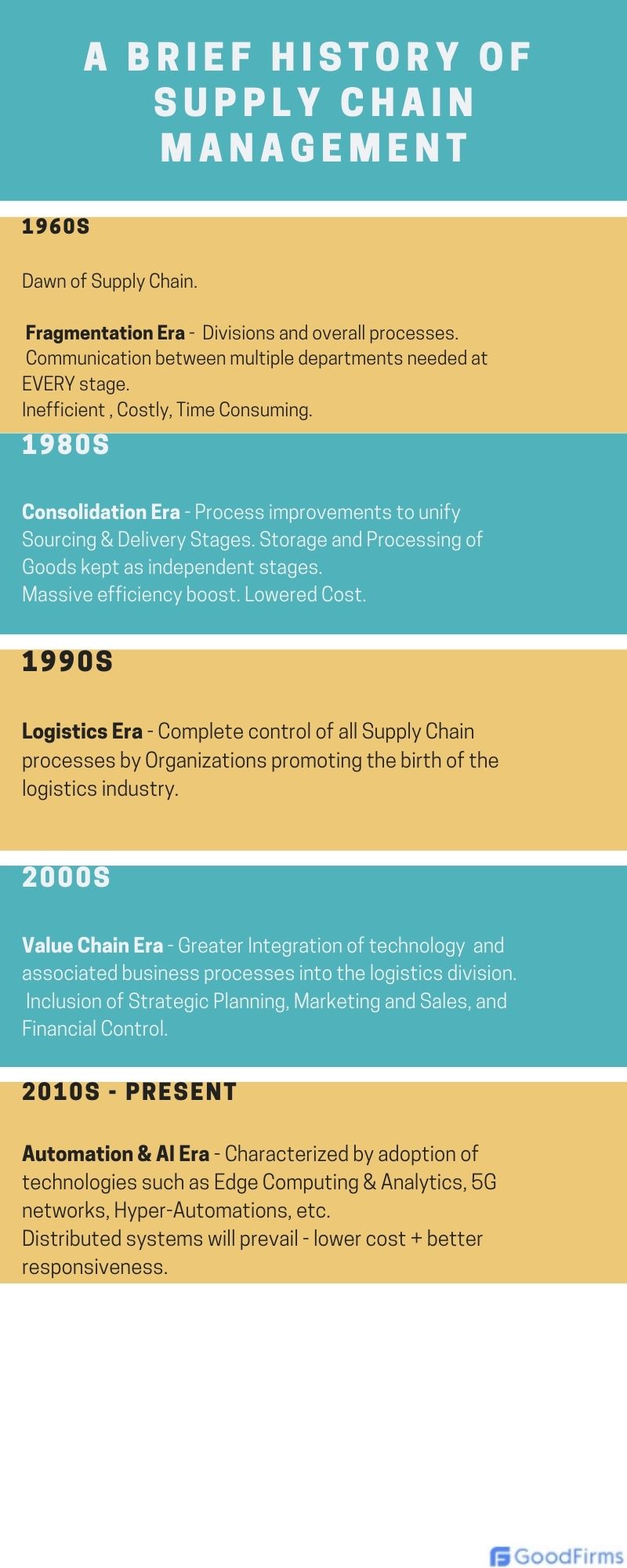

Supply chain management has undergone a revolution rather than a mere evolution. Major technological and process enhancements have led to a leaner supply chain over the last few decades, resulting in major benefits in cost management, and sourcing and delivery functions.

Let’s look at how the Supply chain has developed itself over the years below -

The 1960s - This era spread the boom in supply chain management techniques. However, the shadows of infancy always masked the effective supply planning that was taking place. In this era, the entire supply chain was compartmentalized and fragmented into discrete functions, all of which played an important role in the entire chain. Some of the important activities involved were -

Demand Forecasting, Sourcing, Requirement and Production Planning, Inventory and Warehouse Management, Packaging, Distribution Planning, Order Fulfilment, and Transportation, and most importantly, Customer Service.

Each service requirement intricate channels of communication and were subjected to delays, such that the efficiency of the entire supply chain was hampered. This was corrected in the succeeding era.

The 1980s - Usually termed the era of ‘Consolidation’, supply chain management specialists began to group important activities into one tightly knit unit to facilitate rapid progress on the sourcing and supply front- knowledge annealed from over 20 years of experience in the line of work. This era also marked a shift in the company’s handling of supply chain sourcing, to one that was more in-house and controlled internally.

Processes such as Manufacturing, Sourcing, and Requirement Planning were consigned into the Material Management division of the organization. Similarly, the Physical Distribution of goods was formed from functions such as Goods Inventory, Order Processing, and Customer Service.

Thus, the streamlining of services resulted in a new Supply Chain Management Structure: Material Management, Warehousing, Material Handling, Packaging, and Physical Distribution.

The 1990s - Anyone who believed the era of supply chain evolution had come to an end was mistaken. The 1990s saw companies running supply chains integrate their offerings into one common function - Logistics. This included everything mentioned in the stages above, all handled by the company’s specific logistics division.

The 2000s - Y2K and the decade after it brought out significant technical collaborations and improvements to the supply chain. The logistics division, now a central component of any company’s business structure began to assimilate IT solutions to increase inherent functions. Data mining and analysis, combined with marketing and sales structures helped businesses to use logistics divisions as revenue centers and cut-down overall cost and time, increasing efficiency. This was called Value Creation.

In fact, the entire logistics industry was born out of the 2000s need to enhance distribution and delivery capabilities, throughout industries.

The 2010s and beyond - With the progress in technology and the IT revolution, more and more companies are demanding that Automation and Artificial Intelligence have a greater say in the logistics operations. Trends such as Edge Computing and Analytics, Hyper-Automation, Continuous Intelligence, Supply Chain Governance through 5G, and Immersive Supply Experiences are all expected to play vital roles in the 21st century of Supply chain development.

What is the importance of Supply Chain Management for businesses?

A well-implemented supply chain management process has implications for organizations that span well beyond mere operations. Some of the biggest reasons for businesses to implement best SCM systems are as follows -

- Competitive Advantage - SCMs play a vital role in procurement to final delivery of finished products to customers. A well-designed supply chain is crucial for any business to seize a market.

- Control - Be it wastage, resource deployment, or even costs - Supply chain management is instrumental in giving businesses command over core business functions that play a vital role in production and efficiency.

- Plan - SCM helps businesses plan the entire value chain for optimal delivery of products and services in a streamlined manner. From suppliers to middle-men to last-mile logistics, everyone’s participation is throughout from the beginning. Standards in production and delivery meet pre-set international standards with greater transparency.

- Customer satisfaction - A fluid SCM delivers exceptional quality products and services to consumers on time. It thereby increases loyalty and retention.

- Inter-departmental Communication - Supply chain management technology clears out miscommunication between departments of the organization and helps track the job at every stage.

- Measures of Produce - With supply chain management, you can accurately measure where your chain’s performance is dropping off, what needs to be improved, what can be further optimized in the supply chain, etc.

- Time-Saving - With the intricacies in the processes mentioned above, supply chain management dramatically reduces the time taken from raw material acquisition to final product delivery.

What is Supply Chain management software?

Supply Chain Management software is a suite of digital tools to enhance the supply chain’s functionality - from acquiring raw materials to production and delivering goods to the customer.

The purpose of the software for supply chain management systems is to ensure that the supply chain and adjoining processes are agile enough to react quickly to global conditions, while at the same time maintaining the quality of the product, cost-effectiveness, and efficiency of the process.

Supply chain management software comes in different modules - they can be client-side web-based or cloud-based systems.

What does supply chain management software do?

Supply chain management software systems essentially perform various functions meant to boost business productivity and output further. At its core, the SCM software tool has tasks that cover the supply chain spectrum - forecasting, planning, sourcing, labor division, execution, and monitoring.

Supply chain management software also helps maintain relationships between vendors and suppliers, as well as customers. Its integration with inventory management and warehousing systems alert users of stock-outs and overstocks, contribute to negotiating the supply of raw materials. Specific tools also help manage payments to the business and vendors selling the above.

Unique software tools aid supply chain management because businesses can now better manage inventory and warehouses. Serialized lot tracking, overstock, stockout alerts, just-in-time manufacturing, etc., are a sample of the critical tools the SCM software contains, which reduces wastage in terms of money and resources.

Customer satisfaction involves maintaining the highest quality of the product and delivering it in time. Supply chain management software solutions also deal with the necessity of handling goods returns and exchanges flawlessly, using feedback to improve process refreshments.

Supply chain management software has ample data points at its disposal, telling managers the exact sales forecasts for the next quarter, preparing well for it, and tools for optimal assignment and distribution of labor and resources. Besides the above, shipment tracking is also a feature within this set, helping managers single out pain points in the company’s delivery arm.

Finally, an important feature is mobile capability and integrations. Imagine the power of shared distributed resources when combined! That is what supply chain software offers, the ability to perform operations with third-party resources and enhance the value chain for customers and vendors.

What are the features of the Supply Chain Management software?

An online supply chain management software needs to meet a set of functionality criteria. Here are some features that need inclusion in the ideal supply software:

What are the advantages of Supply Chain Management Software?

SCM system software is irreplaceable owing to its advanced set of features. They help optimize an organization’s manufacturing functions and improve the quality of the final product to consumers.

Some of its most significant advantages are as follows -

Top Free and Open Source Supply chain management Software

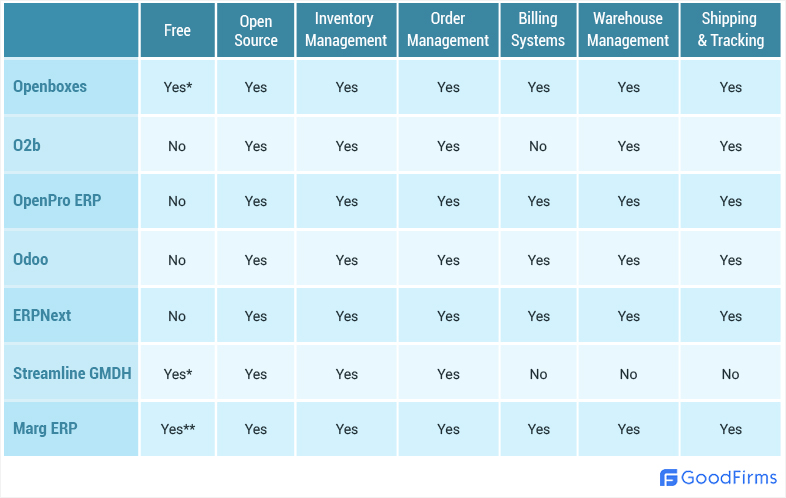

Yes* - Freemium Version offered

Yes** - Free Demo

#1 Openboxes

This Supply chain management system software is a free and open source solution explicitly developed by supply chain professionals. Openboxes is a low-resource environment software, i.e., companies where electronic and physical infrastructure is limited. With a completely customizable interface and user-friendly workflows, this SCM software helps businesses plan inventory management and forecast better when in uncertain business conditions.

The Openboxes community members continuously innovate the product around healthcare supply chains, and support is available in three languages. The software’s base version is an on-site solution and is free of charge, but more advanced versions require payment.

Source - Openboxes

Some of the features of OpenBoxes are as follows -

- Inventory Management & Tracking

- Stock Movement Tracking

- Reporting and Analytics Dashboard

- Security

- Flexible location Hierarchy

- Email and Notification Support

- Multilingual Support

- Electronic Stock Card

- Rest API

- Flexible Deployment

- Stock List Management

#2 O2b Technologies

This open source Supply chain software solution helps businesses run a smooth operations network with their platform. O2b’s system is a tightly integrated software capable of making the entire supply chain process smooth. The creator of the supply chain management software system promises long-term profitability and sustainable efficiency in production. The supply chain management software system also assures it will enhance basic operations visibility across the entire supply chain, and advanced shipping techniques.

Source - O2b Technologies

Some of the features of O2B Technologies’ software are as follows -

- Inventory Management

- Warehouse Management

- Product Advancement and Returns Management

- Order fulfillment

- Sales Forecasting

- Reporting and Analytics Dashboard

- Inbuilt CRM

- Manufacturing Management

- Transport and Logistics Management - Advanced Routing, Drop-Shipping, etc.

#3 OpenPro ERP

This supply chain management solution is an open source supply chain management software to enable wholesalers and distributors to control operations better, inventory, and customer service. Specifically designed for high volume customers, the SCM system software helps buyers implement just-in-time delivery, improves supplier efficiency through reporting, and provides strategic sales improvement through real-time data analytics.

Source - OpenPro ERP

The software is available on a quote-based pricing mechanism. OpenPro’s Supply chain management system software is an entirely web-based solution and helps small and medium scale businesses optimize their ERP systems’ performance.

Some of the features of OpenPro are as follows -

- Real-Time Delivery Monitoring

- Built-in CRM

- Multiple Application Integrations

- Sales History Reporting

- Inventory Control

- Warehouse Management

- Demand Forecasting

- Multi-level Pricing & Discount Management

- Reporting and Analytics Dashboard

- Multi-tier Commission tracking

- Barcode Reader

- RFID Tracker

#4 Odoo Inventory

Another gem out of the Odoo stable, the open source supply chain management software solution offers easy integrations with various applications. Odoo themselves serve over 5,000,000 customers, and they’ve made this solution as complete as the rest of their products. The heart of the supply chain management tool consists of double-entry inventory systems, which improves performance and maintains just-in-time stock. It also uses automation in several processes and uses an algorithm called advanced routes for package shipment.

Source - Odoo

Some of the features of Odoo Inventory systems are as follows -

- Inventory Management

- Double-Entry Stock Keeping

- Delivery Orders

- Packing, Repairs, Receipts Management

- Advanced Routing - Drop Shipping, Cross-Docking, Push & Pull Routes

- Barcode Scanning

- Custom Alerts & Scheduler

- Serial Number Tracking

- Inventory Valuation

- Product Recording - Types, Expiry Dates

- Reporting and Analytics Dashboards

- Third-Party Tool Integrations

#5 ERPNext

Rated as one of Gartner’s best open source supply chain management software, ERPNext finds usage in over 5000 global companies as one of the best supply chain solutions to use. It’s not too expensive either, with the base version priced at just $245 per user for a yearly package, while the enterprise version is dependent on quote-based pricing. Overall, the tool provides a real-time view of your business’s key performance indicators (KPIs). At the same time, the software also allows for variations in the item to be tracked effortlessly.

Source - ERPNext

Some of the other essential features of ERPNext are as follows:

- Serial Number Tracking

- Lot Management

- Vendor Management

- Request for Quotations

- Email Notifications

- Supplier Portals

- Promotional Schemes

- Stock Replenishments

- Multilingual Supply Chain Management

- Automated Invoicing

- Accounts Payable

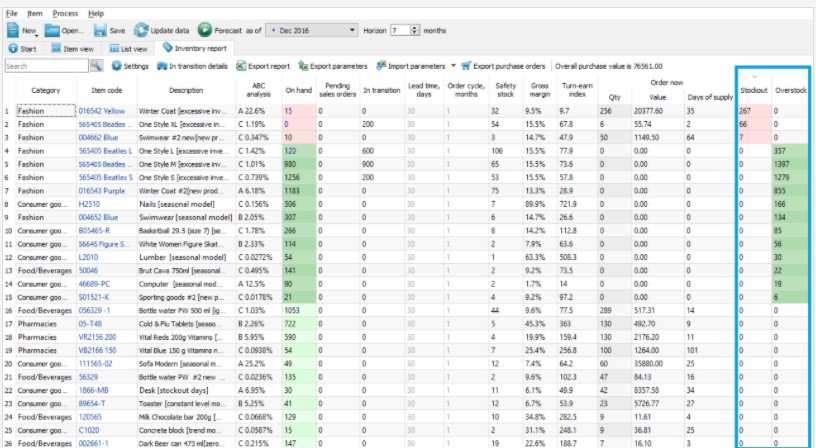

#6 GMDH Streamline

It is a free supply chain software solution that currently helps merchants and vendors manage $3 billion in inventory. The company claims to help its clients forecast and plan orders twice as fast while decreasing the risk of stockouts and excess inventory. The free supply chain management software boasts of a smooth UI interface and some exceptional software integration capabilities. It has other feature-laden premium versions, which are available on a quote-based Pricing system.

Source - Streamline GMBH

Some of the best features of Streamline GMDH are as follows -

- Demand Forecasting

- Inventory Management and Control

- Order Planning

- Stock-outs/Overstock Alerts

- Calendar Events and Promotions

- Material Requirements Planning

- New Products Forecasting

- Analytics and Reporting Dashboard

- Inventory Optimization

- Third-Party Integrations

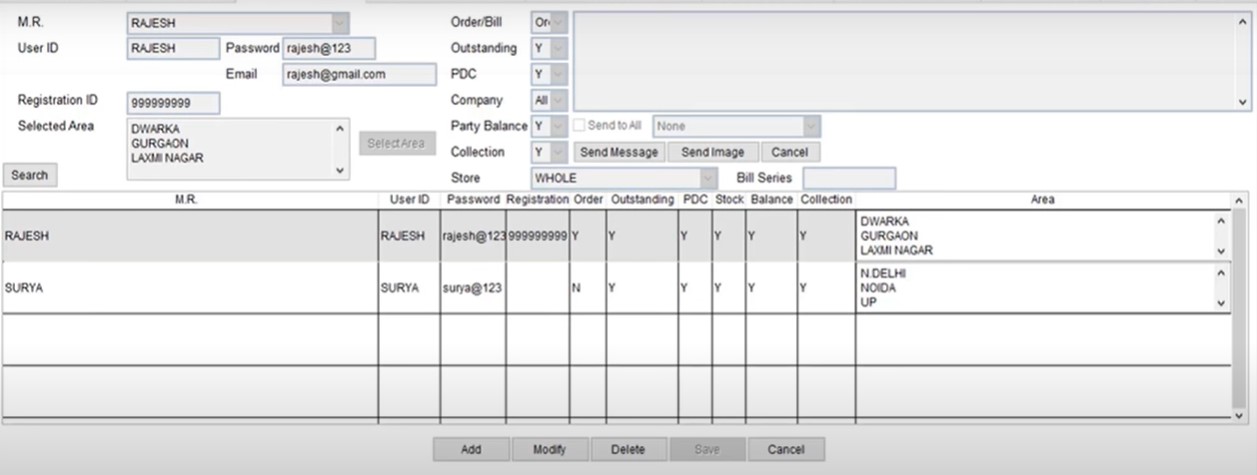

#7 MargERP

Marg ERP is a supply chain management tool which assures buyers of incredible advantages in order fulfillment, scheduling, and supply chain optimization. The India-based company supports over 850 unique businesses and claims to process over $100 billion transactions every year. The supply chain software’s highlights include ensuring the business is tax compliant, collaborating features, and easily customizing it. The SCM system software also assures business users of a competitive advantage thanks to its flexible and suite of advanced features.

Source - MargERP

Some of the most critical features of Margsoft’s Supply chain management software include:

- Sales Analysis using Google Maps

- Warehouse Management

- Inventory Management

- Auto-cloud Back-up

- Reporting and Analytics Dashboard

- Live Credit Limits

- Discount and Price recording

- E-Invoicing

- Order Tracking

- Purchase & Sales Claim

- Tagging & Collection

- Data Security

- Push Sales

There exist several options in the market, each with a comprehensive and unique set of functions such as Blue Ridge, Blue Yonder Supply Planning, and Netsuite. However, none of them are as popular as Anaplan, whose features we will delve into in the section below.

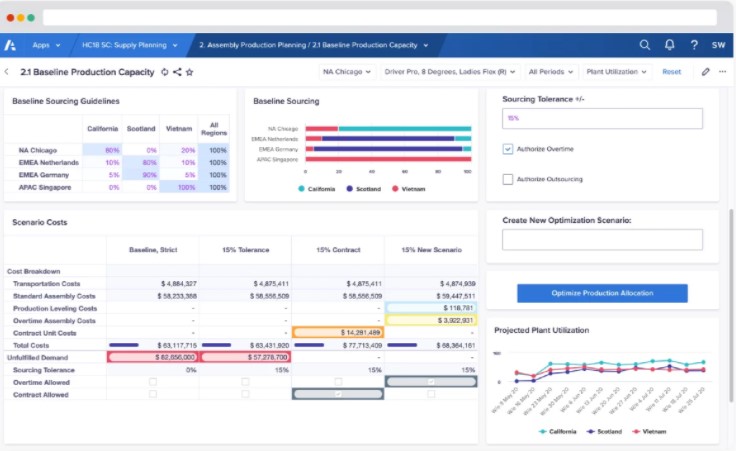

Anaplan (Popular)

The company has built its supply chain management software system keeping in mind the need for businesses to raise a competitive advantage in the operations department. The company combines synchronized agility and unmatched real-time analysis to deepen the online supply chain management software’s capabilities.

The company’s core principles revolve around planning for supply, demand, and sales. Its intelligent supply chain modeling helps create virtual models of your supply chain for you to “unlock end-to-end visibility and control.” Anaplan also helps users plan through incredible enterprise-wide collaboration and third-party integrations to enhance insight.

Source - Anaplan

Some of the features of Anaplan are as follows:

- Supply Planning

- Inventory Optimization & Planning

- Pricing and Promotions Control

- Supplier Spend & Analytics

- Supply Chain Risk Management

- Demand Sensing and Planning

- Customer Collaboration

- New Product Development

- Project Portfolio Analysis

- Supplier/Vendor Collaboration

- Supply Chain Finance and CapEx Planning

Conclusion

The importance of digital control over a business's supply chain will only increase as we move forward. Supply chain management software’s multiple iterations in the digital era make it an indispensable option in today’s market. Whether businesses need to pin-point faults in their present set-up or optimize and streamline others, software for supply chain management systems will dominate companies’ operations departments.

Cast away all your doubts about purchasing the best supply chain management software with our exceptional Buyer’s Guide, all at your fingertips. If you have used any of the software mentioned in our article, please give us your reviews on our dedicated feedback portal. Use the comments section below to give us your opinion on the article.

Be sure to refer to our dedicated Software Directory for information on every software solution in the market.