Trusted, experienced product design, development and manufacturing partners for our indoor hydroponic garden system.

The combination of production-optimized design & process management led to:

• Eliminating expensive equipment

• 10x reduction in production time and labour costs

• 40% reduction in manufacturing space

• Over 60% reduction in cost on the optimized elements, and 20% savings in overall unit cost

• Shortened lead times

What was the project name that you have worked with Inertia?

Just Vertical - Indoor Hydroponic Garden System

What service was provided as part of the project?

Engineering Services

Describe your project in brief

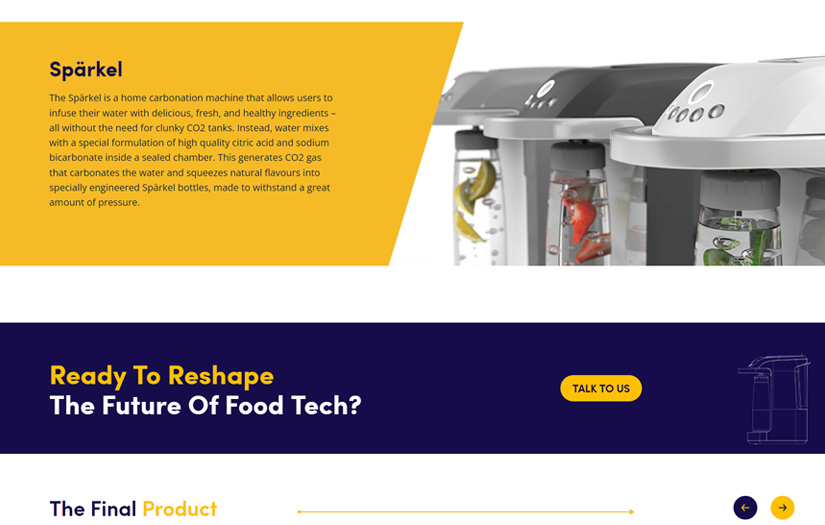

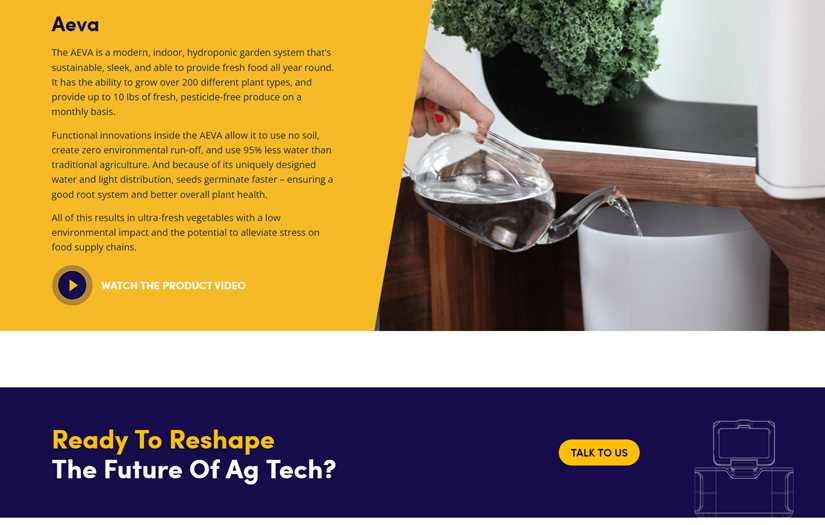

We started with the goal of designing & manufacturing our first in-home hydroponic grow garden, the AEVA. We learned through the process that it would be more efficient to also develop our smaller version the EVE at the same time, so worked on both projects simultaneously in the end.

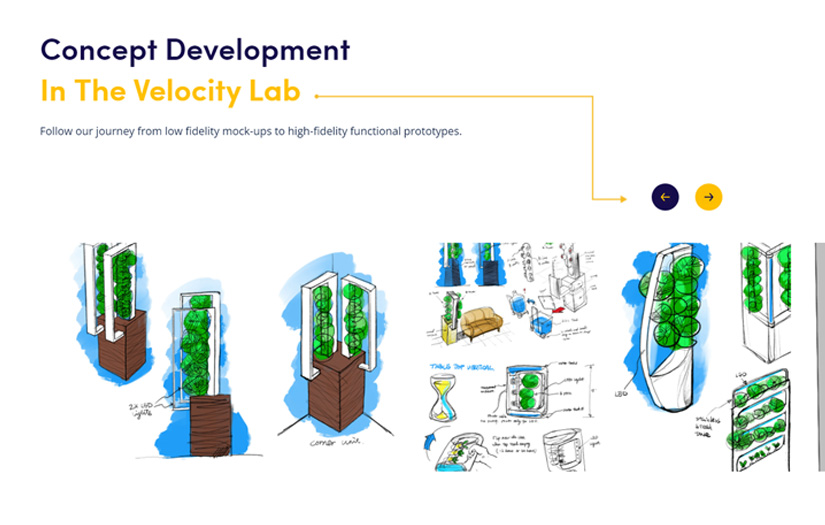

A high-level overview of the stages:

• A range of concept designs led to the development of a “looks like / feels like†prototype

• Both the exterior and interior of the product, went through a redesign for scalability and manufacturability, consolidating the number of parts and integrating several production processes

• Inertia managed our tooling build and delivered a pre-production pilot run and confirmed parts met our quality requirements

• Production of our first order had it in-market by Q4 2021

• We are now scaling up volume and mass production with our second order

What is it about the company that you appreciate the most?

Their teams had a broad range of experience and backgrounds

High level of collaboration between our team and project managers

Full suite of design and project management services as well as manufacturing and supply chain support

What was it about the company that you didn't like which they should do better?

Better upfront communication about the extended use of the prototypes might have helped ease our apprehension about upfront costs.

Rating Breakdown

- Quality

- Schedule & Timing

- Communication

- Overall Rating

Project Detail

- $200000+

- In Progress