Their team is highly skilled and professional.

What was the project name that you have worked with EnCata?

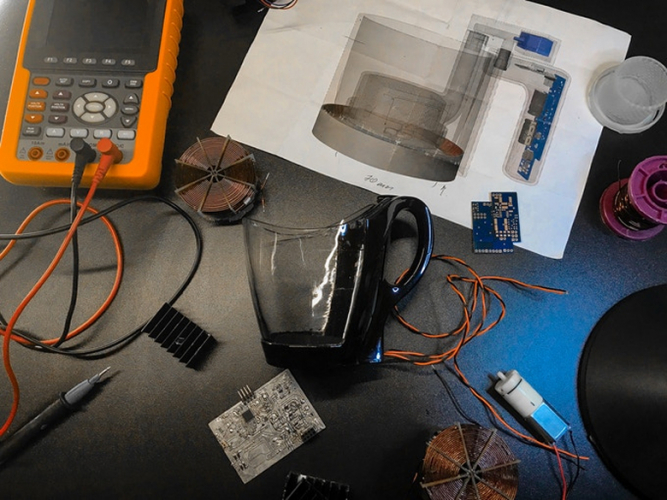

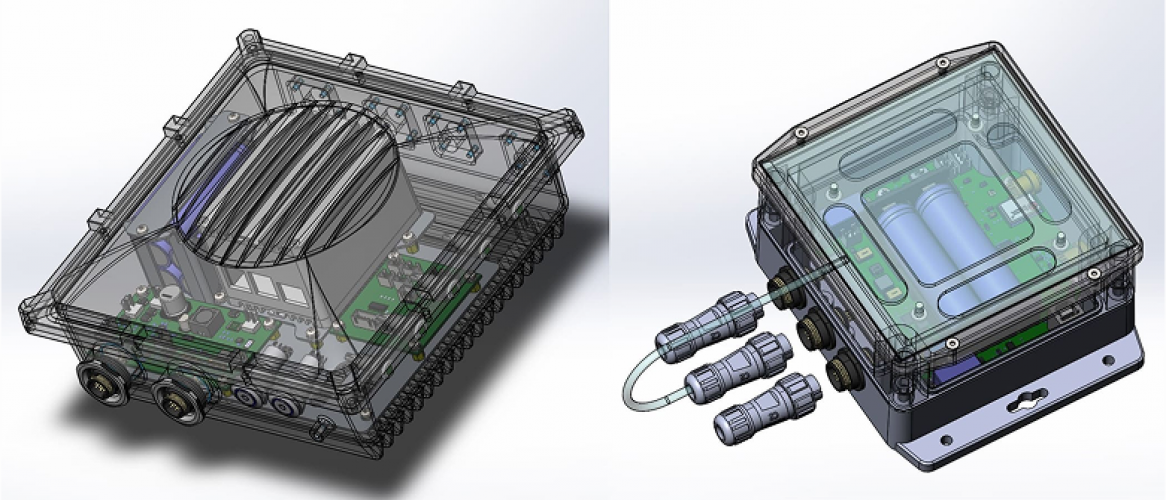

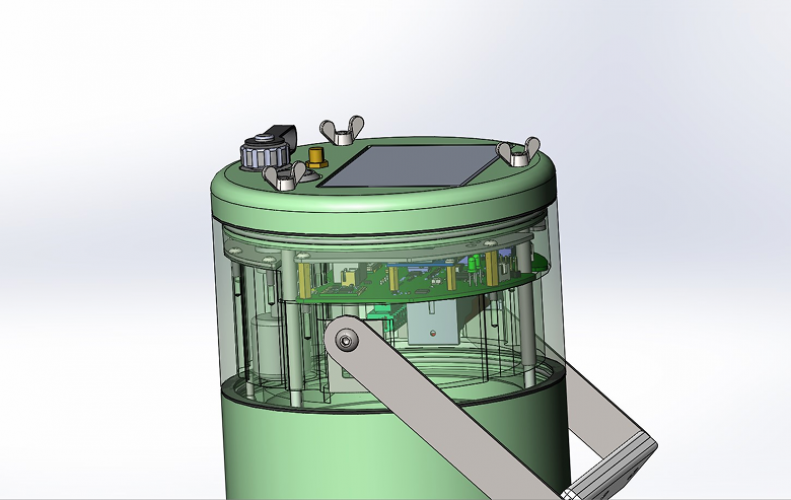

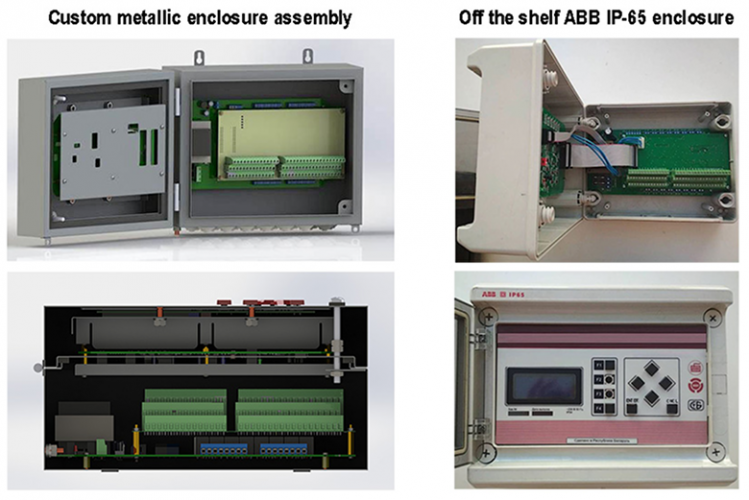

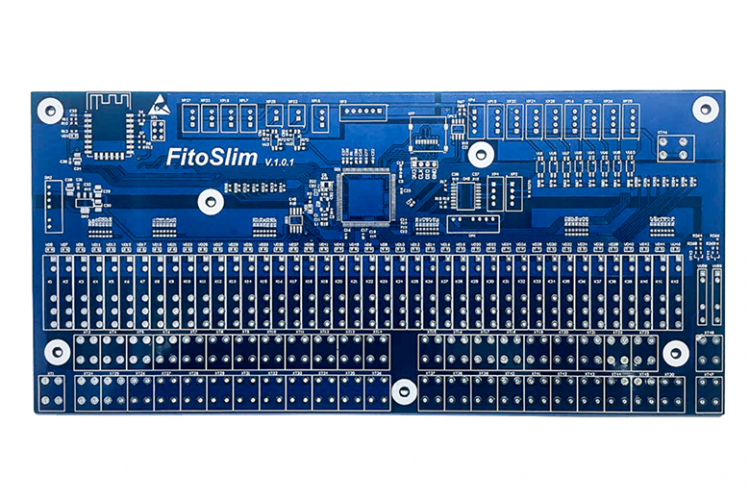

Hardware development for complex IoT projects

What service was provided as part of the project?

IoT Development, Engineering Services, Robotic Process Automation

Describe your project in brief

We have been successfully collaborating with Encata for about two years on IoT projects, where Encata handled the hardware development while we were responsible for the software. Over this time, we have completed a couple of projects.

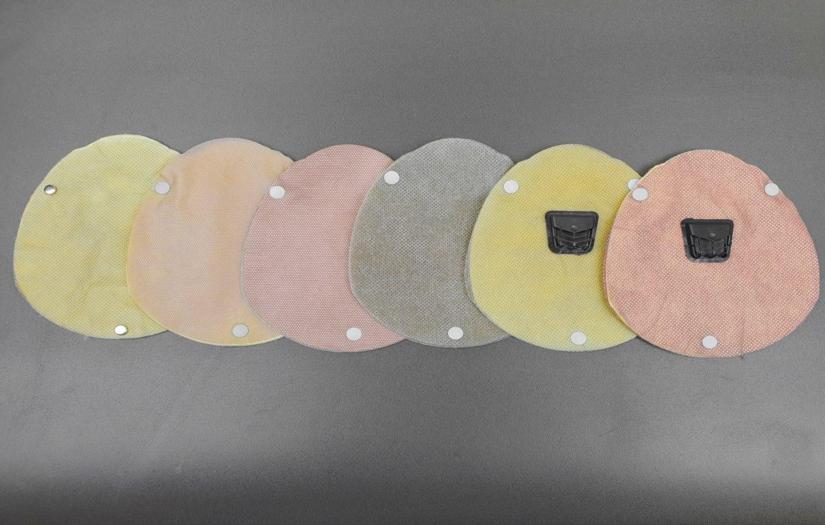

1. Smart Pet Tracker with the following key functionalities:

GPS Tracking: Real-time location tracking for monitoring pets.

Activity Monitoring: Tracking steps, distance traveled, and calories burned.

Behavior Monitoring: Insights into sleep patterns, playtime, and activity levels.

Geofencing: Virtual boundaries with alerts when a pet enters or leaves a designated area.

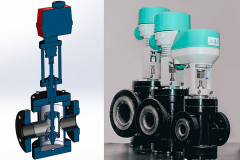

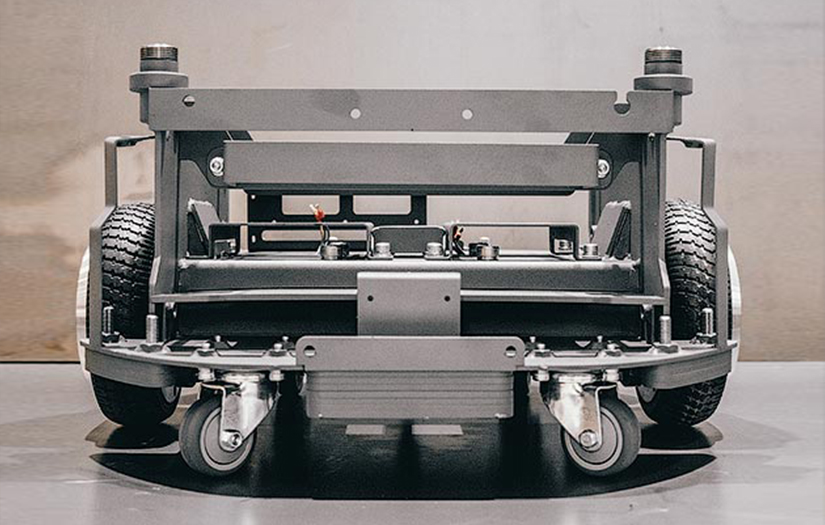

2. Smart Parking Solution:

Development of smart parking barriers controlled via a mobile app, covering the full product lifecycle from conceptualization and requirements gathering to hardware design, prototyping, and final production.

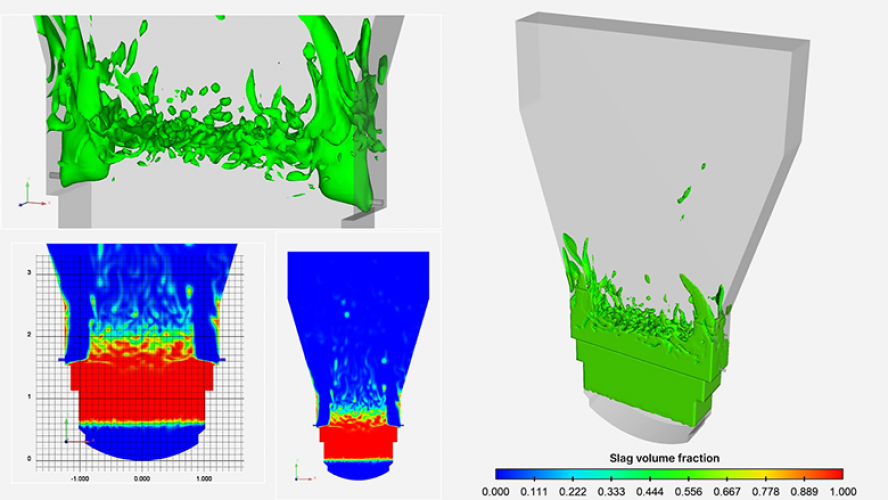

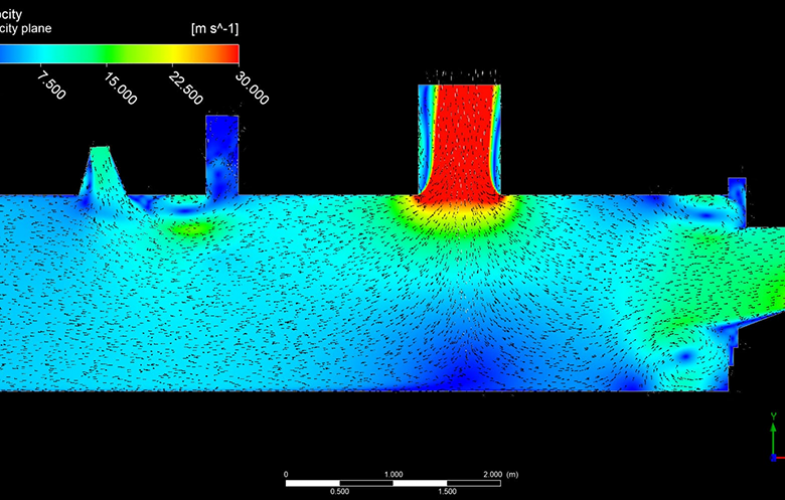

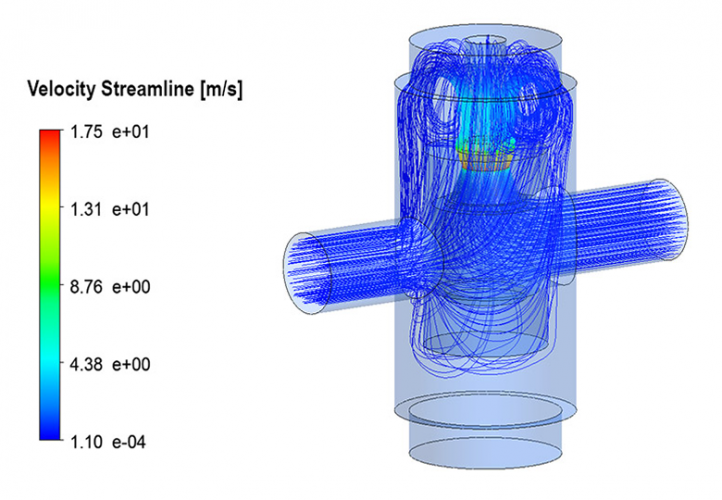

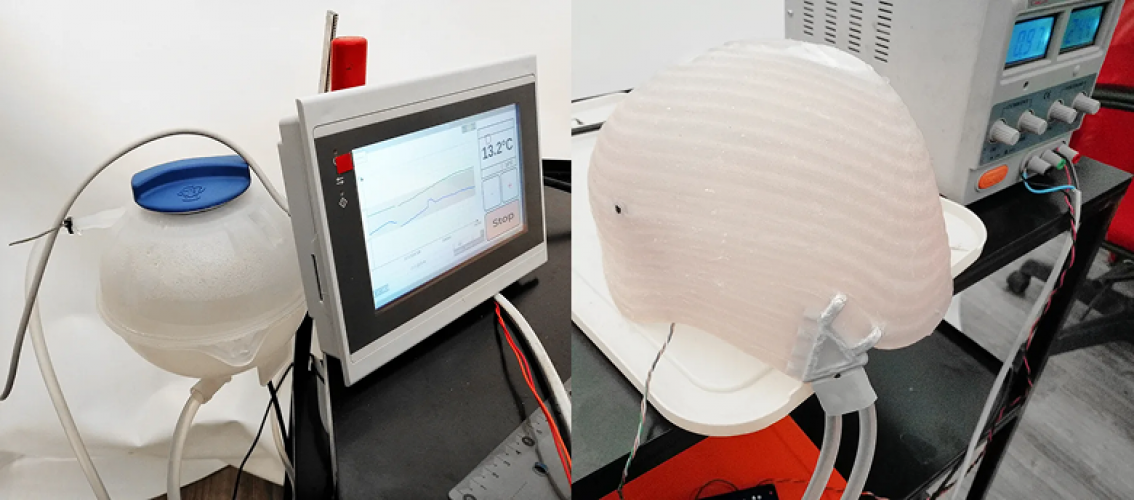

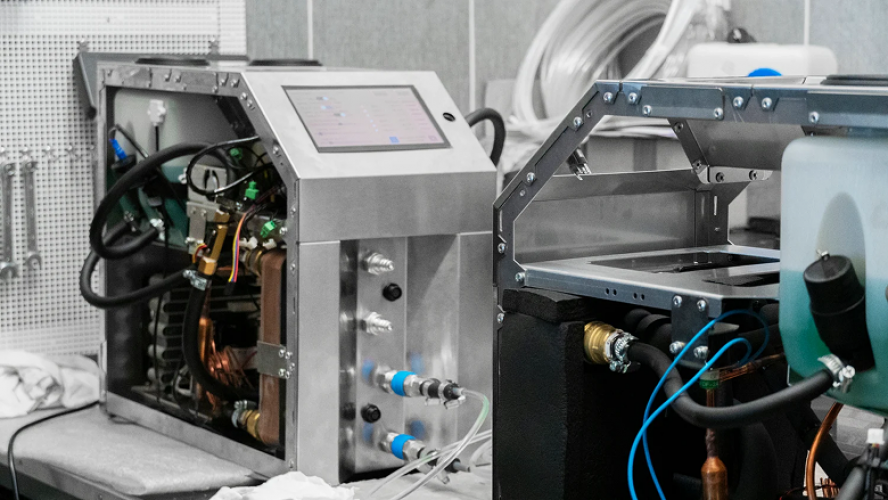

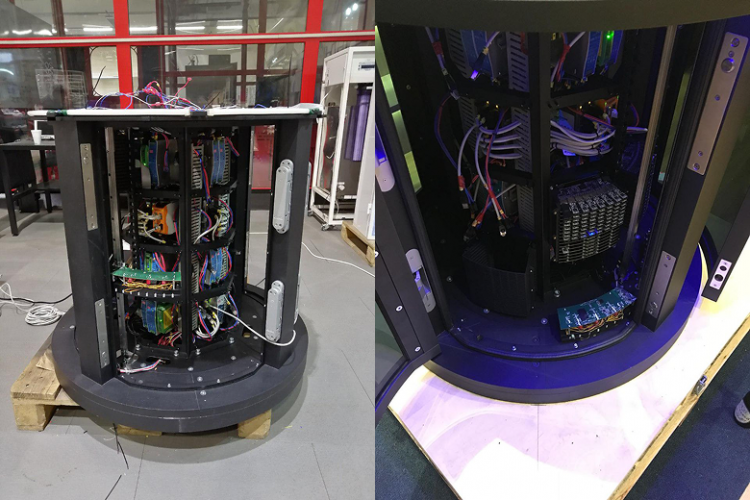

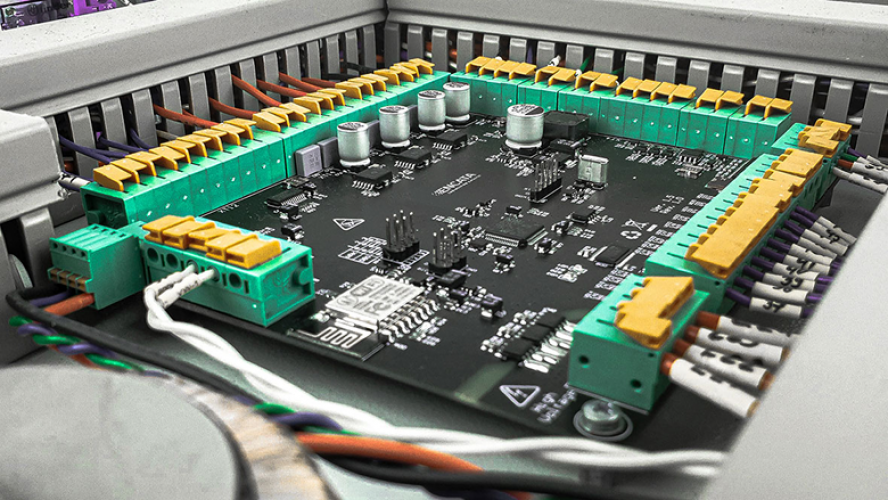

3.Industrial Water Monitoring System:

Providing a smart monitoring and management system for large industrial water tanks supporting mining operations.

What is it about the company that you appreciate the most?

1) On-time delivery – crucial for keeping our projects on schedule. 2) Technical expertise 3) Flexibility and full-service capabilities – having all necessary hardware-related expertise within one company.

What was it about the company that you didn't like which they should do better?

We haven’t encountered any major issues that would impact our partnership. Naturally, no collaboration is without its challenges, but thanks to open and consistent communication, we were always able to resolve them effectively with minimal impact on the final outcome. We highly value our partnership and look forward to continuing our collaboration on future projects. If you’re looking for a reliable, knowledgeable, and capable hardware development partner, I strongly recommend them!

Rating Breakdown

- Quality

- Schedule & Timing

- Communication

- Overall Rating

Project Detail

- $200000+

- In Progress

- Information Technology

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)