PSA

Providing Solutions for Tomorrow - Since 1993

PSA is an ISO-certified developer of Enterprise IoT solutions. We have helped start-ups and global leaders move to digital for over 25 years. Our specialists can build the entire IoT ecosystem from scratch, helping companies get a fully customized real-time intelligent view of their business to improve their daily business processes and profitability. We can help our customers complete their IoT ecosystem development projects at any stage on schedule and within budget.

Certifications/Compliance

United States

United States

Featured Companies

Service Focus

PSA's exceptional IoT Development services give clients a considerable advantage over the competition.

PSA's exceptional Other Services services give clients a considerable advantage over the competition.

Industry Focus

- Automotive - 20%

- Manufacturing - 20%

- Transportation & Logistics - 20%

- Other Industries - 20%

- Healthcare & Medical - 10%

- Oil & Energy - 10%

Client Focus

Detailed Reviews of PSA

Client Portfolio of PSA

Project Industry

- Healthcare & Medical - 19.4%

- Manufacturing - 13.9%

- Other Industries - 19.4%

- Transportation & Logistics - 13.9%

- Oil & Energy - 8.3%

- Retail - 5.6%

- Art, Entertainment & Music - 5.6%

- Automotive - 5.6%

- Information Technology - 2.8%

- Food & Beverages - 2.8%

- Industrial - 2.8%

Major Industry Focus

Project Cost

- Not Disclosed - 100.0%

Common Project Cost

Project Timeline

- 1 to 25 Weeks - 38.9%

- 26 to 50 Weeks - 33.3%

- 51 to 100 Weeks - 22.2%

- 100+ Weeks - 5.6%

Project Timeline

Clients: 5

- SCI Distributors

- Kohler

- Livio

- Perdue Farms

- B B SmartWorx

Portfolios: 36

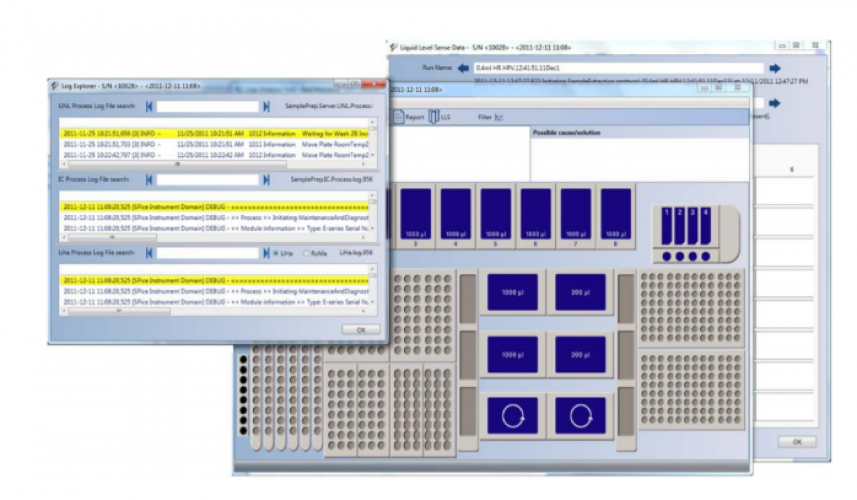

Troubleshooter for Diagnostics Platform

HIGHLIGHTS

A global healthcare technology provider sought to optimize the maintenance of their molecular diagnostics platform, which supports a wide range of IVD assays. The equipment performs sample preparation, featuring a handling arm for liquid dispensing and sampling, robotic arm for sample manipulation, and barcode readers for sample and reagent tracking. All these components demanded costly maintenance.

CHALLENGE

Client Challenge

Reduce maintenance-related expenses for the IVD equipment.

Project Objective

Enable rapid and accurate troubleshooting during IVD equipment operation.

SOLUTION

The PSA team developed an equipment-compliant software tool, providing interactive troubleshooting through rapid search and handy graphical representation of system errors.

A 2D view of the worktable, liquid handling, robotic manipulation, and barcode identification areas highlights green dots for the error-free locations and red dots on the error-present ones. By clicking on red dots, the user can access a detailed error overview, including frequency and type.

The tool functions as a log files analyzer, identifying hardware, software and human errors. To enable comprehensive troubleshooting, we implemented:

- 1. Simultaneous exploration of actual log files

-

2. Error browsing

-

3. Receiving well-organized measurement data on each device location

-

4. Data export for further analysis

PSA designed the GUI, creating interactive screens for seamless user interactions, followed by comprehensive software development and testing.

As a result, our client has received a precise, real-time troubleshooting tool, enabling timely error detection and root cause analysis to prevent costly maintenance of diagnostics equipment.

DEVELOPMENT INCLUDED

- 1. Requirements definition

- 2. GUI design & development

- 3. Software development

- 4. Functional testing

- 5. Acceptance testing

RESULTS

-

1. Accurate, real-time troubleshooting

-

2. Significant maintenance cost reduction

TECHNOLOGY BREAKDOWN

Technologies

- 1. .NET

- 2. C/C++

Industry

- Healthcare

Project size

- 1 Business Analyst

- 3 Software Engineers

- 1 QA Engineer

Duration

- 5 months

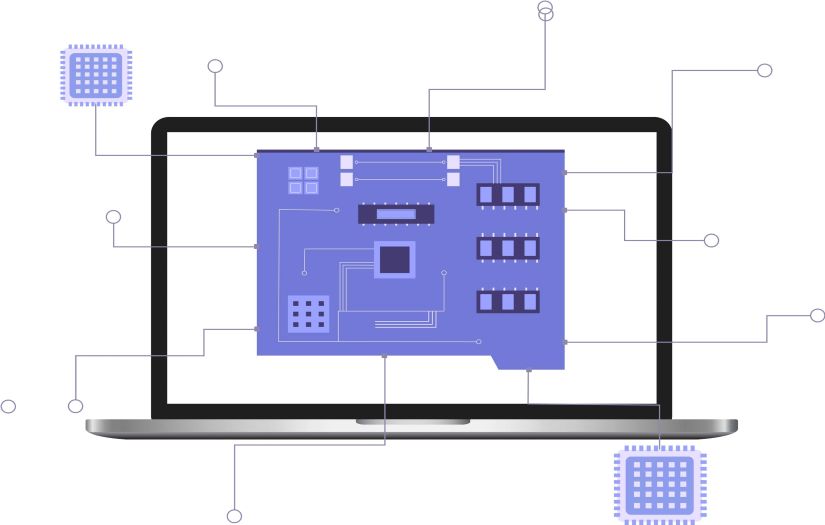

Streamlined Development for Future-Ready SSDs

HIGHLIGHTS

A world leader in memory and storage solutions powering intelligent devices sought PSA’s embedded expertise to accelerate their latest SSD development. To expedite the process, they pursued parallel hardware and firmware development. This required extensive simulation, as some components were still under development.

CHALLENGE

Client Challenge

Eliminate downtime and excessive activities in the development of a state-of-the-art SSD and its future updates.

Project Objective

Implement garbage collection functionality for the client’s SSD without direct access to its components, while optimizing code management processes.

SOLUTION

PSA’s team became an integral piece of the client’s project. At the initial stage, we supported the definition of requirements by outlining functional capabilities, designing mock-ups of screens and reports, and detailing use cases for the Garbage Collection Engine.

Due to the client’s primary controller being under development, PSA employed C-model representations in a simulation environment. We modeled garbage collection functionality with all necessary interfaces, incorporating SSD firmware features and interactions with other blocks.

To ensure high-performance operations, our team implemented:

- 1. Operations control to manage memory reclamation processes

-

2. Reading operations for efficient data processing

-

3. Writing operations for accurate data placement in available memory

In parallel, we helped our client accelerate product development and future updates by creating an auxiliary tool that simplified code management, ensured consistency, and promoted reuse. This tool provided unique, user-friendly templates tailored to the coding styles and expectations of each developer. By utilizing this tool during development, the result was a more stable and efficient system.

DEVELOPMENT INCLUDED

- 1. Requirements definition (onsite)

- 2. Architecture design

- 3. Software development

- 4. Unit & system testing

RESULTS

- 1. Rapid development and market launch

-

2. Cost savings with eliminated project downtime

-

3. Future-proof system

TECHNOLOGY BREAKDOWN

Technologies

- Python

- C/C++

Platform

- Linux

Industry

- Manufacturing

- EIoT

Project size

- 4 Software Engineers

Duration

- 5 months

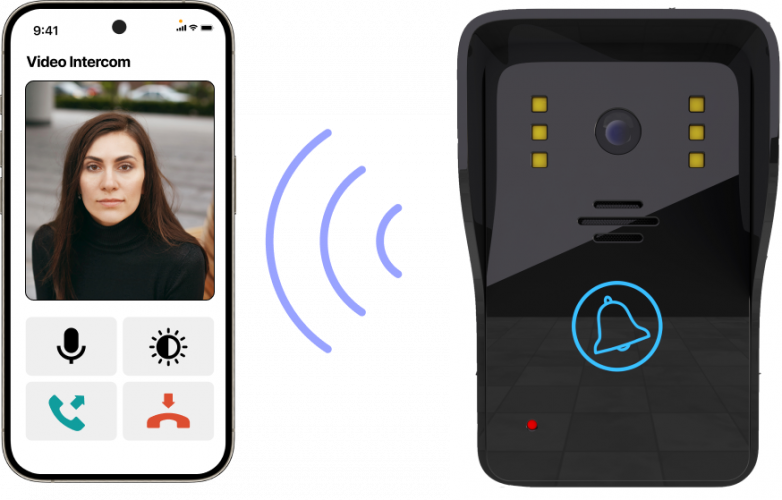

Smartphone-Based Access System

HIGHLIGHTS

After upgrading the client’s intercoms to a comprehensive security management system, PSA was entrusted with further enhancing their product line. The next step was to strengthen access control through a mobile app, making it a key link in building a robust security ecosystem.

CHALLENGE

Client Challenge

Empower the security management system by providing smartphone-based access control.

Project Objective

Create a mobile app that provides access intercom functionality, to be integrated within the client’s security management systems.

SOLUTION

To ensure the app functioned effectively as an intercom, the PSA team conducted a deep investigation into the client’s devices and identified the most suitable connectivity options. We reviewed the original system’s functionality and capabilities to set clear business objectives and use cases and delivered an initial UI demonstration to align expectations.

Running on both iOS and Android, across smartphones and tablets, the intercom app enables reliable communication and access to premises. It acts as the central coordinator and controller for all intercoms deployed on-site. We ensured the app delivered the following key features:

-

1. Device discovery in the network using the proprietary protocol

-

2. Audio and video calls between doors and the app, as well as app-to-app communication

-

3. Secure door release functionality with SSL encryption

-

4. Broadcasting messages to multiple devices simultaneously

-

5. Push notifications in real-time

Our team replicated the core business logic of the master intercom, ensuring full compatibility with network devices. Significant efforts were devoted to protocol-level scope, defining and implementing discovery and configuration protocols to seamlessly integrate with third-party SIP stacks, which the client intended to use. Licensing and configuration options were thoroughly researched and integrated to meet all client requirements.

To optimize system performance, we conducted extensive engineering tests to assess memory consumption, ensure smooth business logic implementation, and validate the app's operation in various environments.

As a result, our client received a user-friendly mobile app that controls entry to the premises without the need for an intercom device inside. This innovation allowed the client to offer their customers more advanced and flexible security management solutions, enhancing the overall security ecosystem.

DEVELOPMENT INCLUDED

- 1. Engineering consulting

- 2. Requirements verification

- 3. Storyboards & GUI development

- 4. Software architecting

- 5. Software development

- 6. Testing & bug fixing

- 7. Follow-up support

RESULTS

-

1. The mobile app fully replicates intercom functionality

-

2. The client's security ecosystems have been significantly enhanced

TECHNOLOGY BREAKDOWN

Technologies

- TCP/IP

- Open SSL

- SIP

- Java

- Objective C

- C/C++

Platform

- iOS

- Android

Industry

- Security

Project size

- 1 Software Architect

- 2 Software Engineers

- 1 Technical Writer

- 1 Graphics Designer

Duration

- 11 months

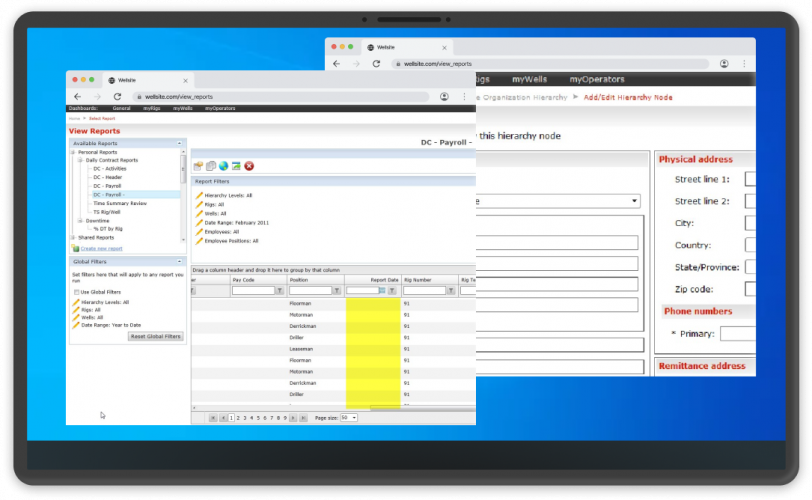

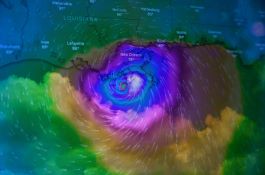

Wellsite Tracking & Reporting System

HIGHLIGHTS

A global leader in providing comprehensive solutions and components for oil and gas production sought to enhance their business intelligence offerings. The proposed solution aimed to access all operational data from wellsites, facilitating the analysis of well performance and downtimes in comparison to neighboring wells. This would empower their customers to proactively identify problem areas and monitor drilling efficiency across the entire fleet.

CHALLENGE

Client Challenge

Amplify the product line with a robust performance tracking platform that enables remote monitoring and continual optimization of oilfield operations.

Project Objective

Develop a secure, highly customizable web-based application for real-time reporting and consolidation of rig-related data.

SOLUTION

Starting with a meticulous market assessment, PSA has helped the client to maturate their concept, ensuring it captured the most valuable features for long-term customer satisfaction.

Providing browser-based access to critical oil well data, the resulting app consolidates summaries from each rig into a central database, generating comprehensive, well-structured reports using a wide range of parameters. A highly customizable dashboard environment includes the following capabilities:

-

1. View of rig, operational, and payroll reports

-

2. Generation of adhoc reports

-

3. Managing data for company, rigs, wells, and operators

-

4. Role-based access control and user permissions

-

5. Filtering multiple parameters to tailor data display

PSA’s engineering team seamlessly integrated the app with the client’s existing data storage system. We designed branded user interface pages and controls, database structures, and programmatic service interface for the web app’s modules. For the app to efficiently handle large volumes of data, we introduced periodic report updates in relevant areas, rather than relying solely on real-time data. Additionally, we conducted profiling to optimize performance after multiple component updates.

As a result, the client received an advanced business assistant that enables real-time monitoring of oil well performance, organizes data for detailed downtime analysis, and provides instant access to custom, standard, and raw data reports—empowering their customers to make the most informed business decisions.

DEVELOPMENT INCLUDED

- 1. Process and requirements analysis

- 2. Architecture design

- 3. UI development

- 4. Data schema optimization

- 5. Web-based tool deployment

- 6. Application functional and automated testing

- 7. Implementation and integration of reports filters

RESULT

An innovative business intelligence product has been successfully launched.

TECHNOLOGY BREAKDOWN

Technologies

- 1. SQL

- .2. NET

- 3. C#

Industry

- Energy

Project size

- 2 Business Analysts

- 10 Software Engineers

- 3 Quality Engineers

- 1 Technical Writer

Duration

- 2.5 years

Simulation & Upgrade of the Blood Culture System

HIGHLIGHTS

One of the world’s largest manufacturers of medical diagnostic instruments and reagents set out to expand its product line of blood culture systems – intuitive instruments for detecting bacteria in blood. They were preparing to launch a compact version to fit smaller laboratories, and planning further extensions for the original system, which had proven to be quite cost-intensive. Partnering closely with the client’s diagnostics department, PSA stepped in to support the development efforts.

CHALLENGE

Client Challenge

Optimize product lifecycle costs of the blood culture system, considering its development, maintenance, and the launch of new product variations.

Project Objective

Provide simulation and cost-effective modernization for the current blood culture system, while also finalizing the development of the updated version.

SOLUTION

To provide greater flexibility in developing both existing and new products, the PSA team enabled its simulation by providing precise desktop control. For this, we ported the blood culture system software from embedded (VxWorks) to Windows OS, allowing it to connect to the existing hardware simulator. Our engineering team carried out:

-

1. Business logic modifications to accommodate OS differences

-

2. Porting of the Zinc-based interface to support various screen sizes

-

3. Ensuring the simulation of printing, barcoding, communication ports, reports, and dynamic screen sizing functionality

By validating on the simulator first, PSA enriched the blood culture system with multi-language support, safe reboot, an on-screen keyboard and debug console, and improved alert and barcoding functionality.

To bring the compact blood culture system to market and facilitate its further development, the PSA engineering team made key modifications to two original systems:

-

1. The instrument app to support operations with half of the number of blood vials

-

2. The simulator to match the new product hardware

We updated the source code and interface screens to reflect these capacity changes, while also adding mobile connectivity for smartphone control.

During an onsite trip, we assisted the client with safe and thorough feature implementation, testing, and bug fixing, ensuring the reduced blood culture system was ready for a swift market launch.

As a result, our client gained a precise testing and validation environment for both products while the new product was fully prepared for its market debut.

DEVELOPMENT INCLUDED

- 1. Requirements Clarification

- 2. Proof of Concept

- 3. Software Porting

- 4. Features & Drivers Implementation

- 5. Testing & Bug Fixing

RESULTS

-

1. Simulation apps for both products completed

-

2. Original product modernized

-

3. The new product is market-ready

-

4. Development time and efforts reduced

TECHNOLOGY BREAKDOWN

Technologies

- C/C++

Platform

- Windows

Industry

- Healthcare

Project size

- 4 Software Engineers

Duration

- 16 months

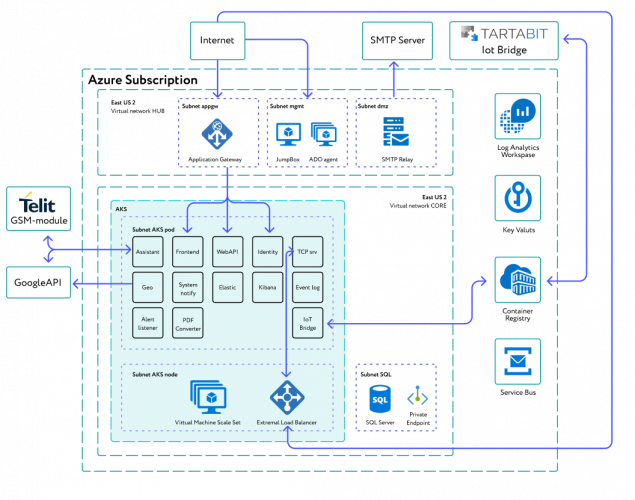

Breach Detection System for Shipping Containers

HIGHLIGHTS

After parting ways with previous contractors, the client sought PSA’s expertise to refine their breach detection product – used by port authorities and shippers to protect cargo on international voyages. Planning to enter key global markets and handle growing demand, they needed to maintain uninterrupted monitoring regardless of cargo location or server strain. Tight deadlines were a top priority, driven by the product's active use and partner commitments.

CHALLENGE

Client Challenge

Ensure frictionless user growth of the breach detection system powering a vast network of IoT devices deployed globally.

Project Objective

Create a flexible and secure platform for smooth operation of the shipping container monitoring service under fluctuating loads.

SOLUTION

The PSA DevOps team leveraged best practices to build a robust, cloud-based infrastructure from scratch in just 30 days, enabling real-time monitoring of widely distributed shipping containers. Our engineers utilized the CI/CD (Continuous Integration/ Continuous Delivery) approach for the client to warrant the time, risk, cost, and labor intensity reduction with app development.

Deployed in Azure, the PSA-built Kubernetes cluster ensures effortless global deployment of the product with reduced complexity and operational costs through the features provided:

-

1. Automatic scaling to adapt to traffic load changes

-

2. Flexible client-server interactions, and licensing management

-

3. Enhanced security for storing keys, passwords, and certificates

-

4. Highly-availability cloud storage for diverse object types

-

5. Automated database management and traffic distribution

-

6. Simplified updates and troubleshooting

We’ve leveraged our partner’s Tartabit technology to smoothly bridge IoT devices to the cloud, as well as Telit technology to obtain device data via their GSM modules.

To ensure high security for both instrastruncure and development processes, PSA team implemented the following measures:

- 1. A private Kubernetes cluster and endpoints for sensitive services

-

2. Protection of incoming traffic and infrastructure management

-

3. Regular updates for virtual machine and operating system

-

4. Role-based access control for Cloud and DevOps platforms

For the service to keep operating without issue, the PSA team migrated the on-prem setup to the newly created Azure infrastructure ensuring no data loss from already running IoT devices. Given the expanded attack surface, we performed rigorous vulnerability tests for each component to validate security.

As a result, our client gained an elastic, resilient, and highly secure shipping container monitoring platform capable of scaling seamlessly to accommodate an influx of users.

PSA continues to support the product by handling network, connectivity, and server issues while optimizing infrastructure and component deployment processes to further enhance system stability and performance.

DEVELOPMENT INCLUDED

- 1. Cloud Infrastructure Development

- 2. CI/CD Pipeline Implementation

- 3. Infrastructure Migration

- 4. Vulnerability Testing

- 5. Ongoing Support

RESULTS

-

1. Cloud-based infrastructure set up

-

2. Smooth global operation under increasing loads

-

3. Ongoing support established

TECHNOLOGY BREAKDOWN

Technologies

- Azure DevOps Server

Industry

- Logistics

- Transportation

Project Size

- 1 DevOps Engineer

Duration

- August 2022 to present

FURTHER COOPERATION

PSA delivered comprehensive product development, including hardware and user app enhancements. Furthermore, we proposed a mux MVP to simplify deployment. The resulting service provides a cohesive, precise, and stable monitoring of shipping containers with real-time breach notifications.

Facility Management Mobile App

HIGHLIGHTS

An eminent design and construction company utilized a native web app to maintain their facility systems, such as HVAC, lighting, plumbing, etc. However, this process created an inefficient incident-response time and subsequent downtimes, which undermined the performance goals of their facilities.

CHALLENGE

Client Challenge

Streamline facility maintenance process by enabling onsite engineers to have all service-critical details at hand.

Project Objective

Create an easy-to-use mobile solution for corporate use providing instantaneous access to equipment-related data.

SOLUTION

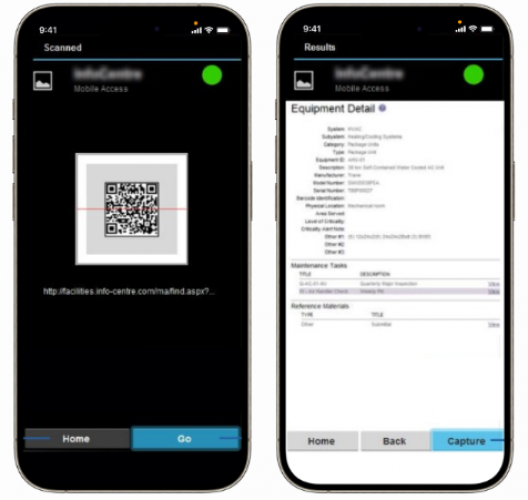

To reduce turnaround time, the PSA team developed a mobile application for the client’s engineers to immediately obtain full maintenance information by scanning QR codes from the onsite equipment. Having the data stored within the client’s core web app, we coordinated the backend modifications to support extension to mobile, providing seamless data exchange and QR code recognition.

Being iOS and Android-compliant, the app provides the following capabilities:

-

1. Login and authentication via username and password

-

2. Testing the connectivity with the main server

-

3. Сamera-based QR code scanning

-

4. Examining equipment maintenance checklist, warranty information, open and closed work orders, and Q&M manuals

To optimize navigation, we introduced clear and consistent user flows through loading, home, setup, media capture, results, help, and about pages.

Finally, we deployed the app through the client’s corporate channels so they could distribute it internally. Additionally, we ported the app with its full functionality to the Windows platform to run on Microsoft Surface Pro tablets used by the client’s staff.

As a result, our client gained an advanced mobile assistant to help hold maintenance at greater efficiency, which subsequently reduced equipment downtime and service costs. This project became ground-breaking for them and paved the way to advanced management and customer interaction opportunities, involving service requests, work orders, and preventative maintenance.

DEVELOPMENT INCLUDED

- 1. Requirements definition

- 2. Storyboards & UI development

- 3. Software Development

- 4. Functional Testing

- 5. Software Porting

- 6. Private Deployment

RESULTS

-

1. Mobile and tablet apps launched

-

2. Incident-response time reduced

TECHNOLOGY BREAKDOWN

Technologies

- 1. Java

- 2. Objective C

Platform

- 1. iOS

- 2. Android

Industry

- 1. Smart Building

- 2. Energy

Project size

- 1 Business Analyst

- 1 Software Engineer

- 1 QA Engineer

Duration

- 10 months

Espresso Coffee Machine with Patented Technology

HIGHLIGHTS

PSA has been supporting an American startup that intends to revolutionize the way coffee is brewed. Their patented technology enables consistent coffee flavor every time without relying on grind size, tamp, and dose. Getting stuck at the prototype stage, they needed the assistance of true embedded experts to rectify the product and finally bring it to market.

CHALLENGE

Client Challnege

Certify and successfully launch to market a brand-new coffee machine, ensuring its highly competitive advantage.

Project Objective

Refine the firmware of commercial coffee machine prototype in order to produce a market-ready product, with the goal of providing the highest performance and UX with cutting-edge technology.

SOLUTION

Having a firmware MVP with limited functionality, PSA provided significant enhancements to provide failure-free operation and consistent control for the machine powered by a robust and feature-rich Toradex Colibri iMX6UL SoM.

With no design documentation, PSA thoroughly examined the firmware source code and recreated the development environment to empower the system with the following features:

-

1. Optimized business logic for correct system operation

-

2. Functional stability regardless of external factors

-

3. Possibility of firmware updates

-

4. Synchronization between devices comprising a coffee machine

-

5. Improved HMI screens for better UX

To address performance issues, we’ve changed the way the device connects by transferring Modbus protocol from TCP to RS-232 interface and implementing a correspondent driver. All testing activities were successfully accomplished remotely by integrating with the client’s machine control simulator.

As a result, our client got an easy-to-use coffee machine with extensive customization options for coffee extraction without compromising performance. While the product is undergoing certification, we keep negotiating its further upgrades before the market launch.

DEVELOPMENT INCLUDED

- 1. Project investigation

- 2. Firmware development

- 3. HMI development

- 4. Product testing

- 5. Requirements review and updates

- 6. Estimation for further updates

RESULTS

-

1. Performance issues eliminated

-

2. The product is undergoing certification

TECHNOLOGY BREAKDOWN

Technologies

- 1. JavaScript

- 2. C/C++

Platform

- 1. Linux

- 2. Embedded

Industry

- Retail

Project size

- 2 Software Engineers

FURTHER COOPERATION

Pending certification completion, PSA has estimated architecture, UX, and functional updates to be implemented before launching the product to market, as well as terms for continuous support. We are happy to claim yet another startup supported and look forward to long-term cooperation.

PSA has been supporting an American startup that intends to revolutionize the way coffee is brewed. Their patented technology enables consistent coffee flavor every time without relying on grind size, tamp, and dose. Getting stuck at the prototype stage, they needed the assistance of true embedded experts to rectify the product and finally bring it to market.

Touch Control for a Coffee Machine

HIGHLIGHTS

The coffee machine manufacturer with a distinguished heritage claimed a superior user experience for their new product. Right in the middle of the project, the developer required the support of out-and-out HMI experts to complete all design activities for the touchscreen-based control under the product requirements.

CHALLENGE

Client Challenge

Superb navigation and control for brewing coffee and payments in the new-gen coffee machines.

Project Challenge

Take over the HMI development to finalize the new-gen product providing enhanced user experience.

SOLUTION

PSA HMI experts with embedded backgrounds have proceeded with the activities on the semi-finished project with a lack of modules while the existing needed a substantial redesign. We implemented and improved several user screens ensuring seamless user control of a coffee machine.

The coffee machine has been amplified with the following:

-

Logging window fixing all the machine events and user actions

-

Sorting and filtering functionality

-

Animated icons for various coffee types

-

Video playback as digital signage during the idle time of the machine

-

Reduction of the page loading time by up to 7x

To ascertain the machine operates as expected, we provided extensive testing for each module to verify integrity, and end-to-end testing, simulating real user experiences thus validating the system as a whole.

DEVELOPMENT INCLUDED

- Product investigation

- Software development

- Unit testing

- E2E testing

RESULTS

-

Tailored user experience for a coffee machine

-

The finalized product ready to be released

TECHNOLOGY BREAKDOWN

Technologies

- JavaScript

Industry

- Retail

- Foodtech

- Manufacturing

Project size

- 1 Software Engineer

Duration

- 4 months

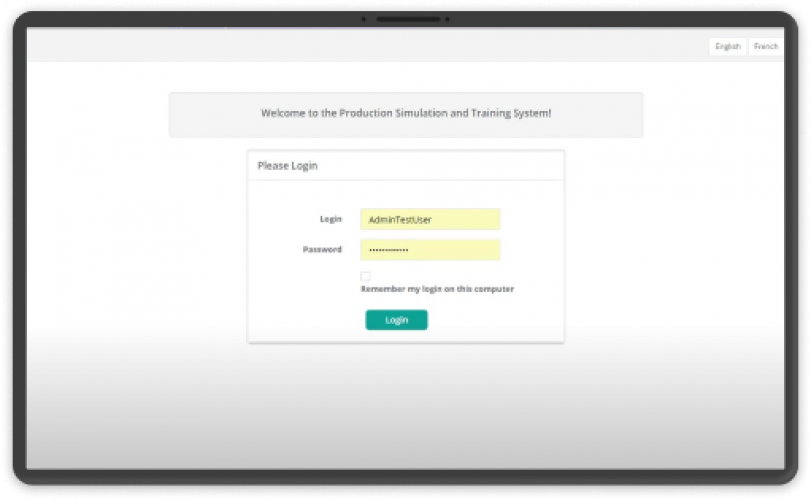

Production Simulation System for Automotive Giants

HIGHLIGHTS

PSA was engaged in developing the production simulation environment to be used for hiring purposes by leading global automotive manufacturers. The highly customizable solution streamlines high-volume recruiting processes enabling rapid, complete, and efficient assessment of whether a candidate complies with the production role requirements. Having the one deployed on the customer’s site, our client requested its substantial advancement to be deployed for their other customers afterward.

CHALLENGE

Client Challenge

Refine the production simulation system in terms of performance, flexibility, and customization to amplify its market value.

Project Objective

Redesign the production simulation system to provide consistent uptime, easy reconfiguration, and simplifying onsite deployment.

SOLUTION

Based on the existing but troubled system, the PSA team has designed a complete architecture for the integrated production simulation system which core can be universally implemented for multiple automotive giants. Primarily, we held onsite sessions for deep-dive system research, stakeholder interviews on business and technical expectations, and environment analysis to engineer functional and non-functional requirements.

The proposed system comprises multiple testing stations simulating a real production environment to assess how a candidate performs work tasks. Modular and interconnected, the designed system involves the following components:

-

Core server module for data collection and participant testing

-

Several simulation station types to meet the needs of assessment centers

-

Inspection station for participant flow and simulation stations management

-

Sensor agents for simulation stations

-

Exams presented with correspondent equipment and connected sensors

-

Brand-customizable web and PC UI

The system is provided with the ability to introduce new station types and substitute modules created by 3rd party through defined interfaces between modules and external systems. We ensured the opportunity of 24/7 remote access via the web browser using a secure connection protocol to enable handy administrator management.

We’ve ensured the system fully satisfies the client’s request by performing the following functionality:

-

Input and import list of candidates and employees

-

Configure assessment exercises

-

Configure the assessment station

-

Perform simulation process operations on stations & process control

-

Score the results and generate summaries with recommendations

-

Transfer test results data to the external HR system

-

Create local backups for test results

The PSA engineering team defined the system option for the primary customer, which required minimized modification of the existing equipment for cost savings. Also, we developed a PoC desktop app for one simulation station with custom peripherals attached.

Finally, the client gained the system architecture document defining requirements for stations, web portal, and administration module, as well as hardware constraints. This included use cases, components descriptions with diagrams showing modules and logical connections, sequence diagrams, interface definitions covering external and internal system interfaces, database schema definition, and deployment diagrams.

DEVELOPMENT INCLUDED

- System investigation

- Onsite requirements definition

- Architecture design

- Software design

RESULTS

-

A refined system meets the urgent production needs

-

High-efficient system concept can be proposed to end customers

TECHNOLOGY BREAKDOWN

Technologies

- Angular

- SQL

- .NET

- C/C++

Platform

- Linux

Industry

- Manufacturing

- Automotive

Project size

- 1 System Architect

- 2 Software Engineers

- 1 Technical Writer

Duration

- 7 months

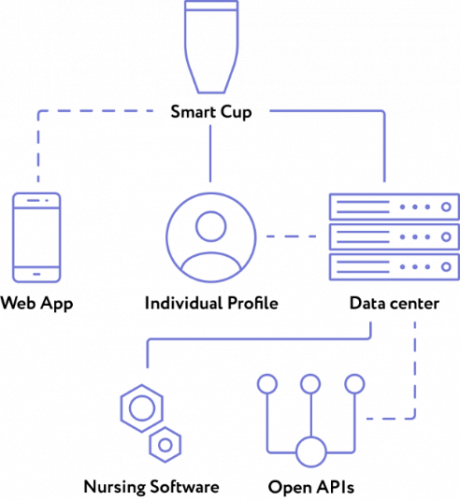

Smart Cup for Hydration Management

HIGHLIGHTS

A high-profile European start-up raised substantial financial support to develop a smart cup for hospital water balance management. The product would automatically control sufficient and regular fluid intake through real-time tracking and notifications to users. To meet already approved deadlines for manufacturing and launching a smart cup without harming quality, the client needed to make up for the missed expertise on embedded development.

CHALLENGE

Client Challenge

Finalize the product in terms of firmware for pilot batch production and start trial operation on a tight schedule.

Project Objective

Implement firmware for a smart cup providing fully-fledged functionality, top-tier performance, and reliable connectivity of system components.

SOLUTION

PSA firmware development activities enabled the smart cup to properly and efficiently perform its core functionality – real-time tracking of fluid intake, data transfer for server-based processing, and notifications to prompt a drink. The PSA engineering team has refined the client’s embedded software prototype in terms of functionality, connectivity, and performance. After PSA involvement, the product gained:

-

Instantaneous server synchronization over IPsec GSM

-

Tweaked business logic for optimized real-world interactions

-

Power management functionality

-

Possibility of updating via OTG modules

We implemented specific drivers to actualize a range of features, such as GSM connectivity, sensor utilization, flash memory management, hardware components communication, and testing opportunities.

Finally, our team delivered a FreeRTOS-based system prototype with end-to-end performance and stability risk evaluation, as well as migration efforts estimation. Our client gained source code, binaries, test plan, and report of testing, and could seamlessly move to the production phase.

DEVELOPMENT INCLUDED

- Product investigation

- Firmware development

- Drivers implementation

- Test plan creation and execution

- Requirements specification creation

- Risk and efforts estimation

RESULTS

-

Delivery ahead of expected deadlines

-

The pilot batch has been sent to production

-

A trial operation has been launched

TECHNOLOGY BREAKDOWN

Technologies

- GSM

- C/C++

Platform

- STM

- RTOS

Project size

- 2 Software Engineers

Duration

- 6 months

Combined Media System for Recording Studios

HIGHLIGHTS

Our client, a fiber optic-based technology provider, intended to introduce a revolutionary modular media system for professional use within recording apps, live sound, and broadcast production. The expected system was to provide best-in-class performance and be able to handle high-throughput data while remaining cost-effective and lightweight. However, the client struggled with financial issues, which forced them to postpone the development.

CHALLENGE

Client Challenge

Resume the promising development and launch to market the high-performance media system for professional use while minimizing financial and technical risks.

Project Objective

Develop firmware and provide remote control for the combined media system to ensure multi-optional data routing over the fiber optic.

SOLUTION

To provide top-notch operation of the future media system, the PSA team developed real-time firmware for all 7 modules of the combined product ensuring their separate and joint operation. The media product provides a full-fledged fiber optic communication system providing data transfer up to 155MBit/s. It comprises the following components running on Atmel’s SAM7 processor and Xilinx FPGA:

-

System controller for internal communication management

-

16-channel microphone preamp for amplification of the microphone’s signal

-

MUX device for combining and transmitting multiple signals over a common medium

-

MADI device for transmitting multiple channels over a single cable enabling high-end audio, and encoding audio information for display

-

Front panel in different variations for the information display and system control

-

Ethernet video processor and transmitter

-

Intercom analog audio processor

The fiber optic hub developed by PSA provides redundant fiber optics commutation logic and supports typical configurations of a star, daisy chain, ring, and hybrid topology. The PSA team also implemented a TCP/IP stack and the client’s proprietary protocol to allow for remote configuring and monitoring of the devices.

To provide the end-user with a system design, remote configuration, and control, we delivered a Windows and Mac-running desktop app, compatible with the client’s industrial platform. Our team provided scalable system architecture based on the plug-ins concept to support new types of audio devices, which dramatically improved the performance, and chat functionality to other network apps.

A rich functionality set allows for flexible system configuration providing:

-

Investigating the network topology and creating the map representation

-

Parameter settings, save and recall configurations

-

Network status display

-

Real-time audio metering data display

-

Multiview support

-

A customizable layout

-

The alternation between on-line and off-line modes

-

Off-line topology creation and editing

Over the initial scope, we offered and implemented a high-end pre-fader listen (PFL) option for the audio module through the host system sound card, thus amplifying product value.

The full range of tests involved board, device, and system-level tests, as well as support of the client's team with beta testing. For the client to be able to modernize their device, we ensured knowledge and technology transfer onsite, as well as long-term support after the product delivery.

DEVELOPMENT INCLUDED

- Requirements definition

- Documentation review and updates

- Firmware development

- Software development

- Board, Device, and System testing

- Documentation creation

- Long-term support

RESULTS

- Ready-to-market high-end media product

- Top performance and cost-efficiency

TECHNOLOGY BREAKDOWN

Technologies

- TCP/IP

- C/C++

Platform

- Xilinx

- Atmel

- Mac OS

- Windows

Industry

- Digital Media

Project size

- 3 Software Engineers

- 1 Hardware Engineer

Duration

- 2.5 years

Car Radio Device Integration

HIGHLIGHTS

A leading global supplier of electronics and technologies for the automotive industry was searching for the optimal component formula for their car radio product line. They approached PSA to provide seamless integration and overall upgrades for the car radio device.

CHALLENGE

Client Challenge

Launch an enhanced version of the car radio utilizing 3rd party CD drive while keeping the same device behavior for the end user.

Project Objective

Integrate CD drive into the car radio while enriching the functionality set of the device.

SOLUTION

Focusing on increased efficiency and smooth operation, the PSA engineering team integrated the 3rd-party CD drive into the Pioneer-based car radio device by porting the drive’s SW framework to the target platform. We compared the operation mode of these two devices, defined code modules to be reused, and updated the firmware for the newly-made device.

Our team adjusted the existing HMI to the new playback hardware (CD), resolving the interface differences between the old and the new UI behaviors. The upgraded car radio device supports a complete set of basic functions like play/stop/eject, load disc, fast forward / fast backward, folder up/down, playlist support, power control, etc. Additionally, we included new functions at the client’s request:

-

1. Music navigator

-

2. Random playback

-

3. Repeat functionality

Extensive bug fixing within the existing device was required to improve overall productivity. Thus, PSA increased speed for consecutive track switching, improved the algorithm to move between folders, fixed long waiting after disc loading, and optimized memory usage.

As an output, the client received a ready-to-launch car radio device with CD support and extended functionality. PSA provided our complete support during the warranty period as well.

DEVELOPMENT INCLUDED

- 1. Firmware Porting and Updates

- 2. UI updates

- 3. Testing & Bug fixing

RESULTS

-

1. Enhanced car radio device is ready for mass production

-

2. Seamless CD functioning within car radio

TECHNOLOGY

Technologies

- 1. Java

- 2. C/C++

Platform

- Embedded

Industry

- Automotive

Project size

- 1 Senior SW Engineer

- 4 SW Engineers

Duration

- 5 months.

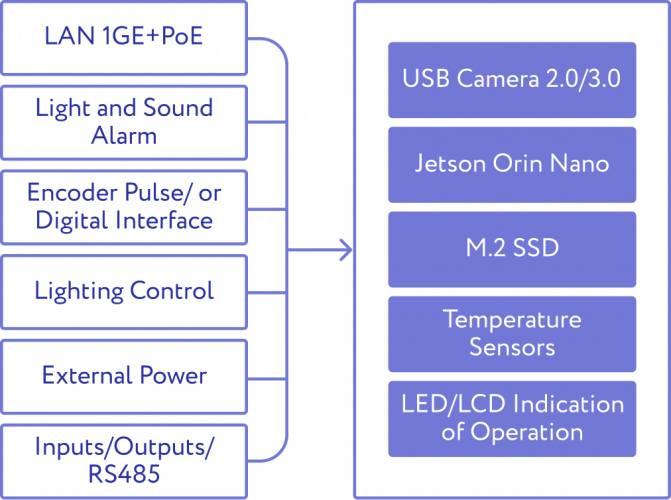

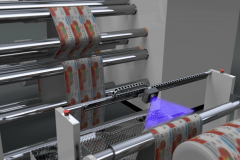

Built-in AI for Defect Detection Device

HIGHLIGHTS

A startup focusing on Machine Learning-based products has collaborated with PSA in the field of production defect detection. Following the successful delivery of the Machine Vision QC System to the printing client, we proceeded to jointly enhance this product before market launch. We focused on the reduction of deployment and mounting efforts, as well as efficiency increase, by putting all the AI computing into the device to support plug-and-play implementation.

CHALLENGE

Client Challenge

Assess the possibility and feasibility of creating a more capacious and efficient QC product for plug-and-play implementation without server AI deployment.

Project Objective

Check the possibility of the current Machine Vision System to perform AI computing within a device. Provide redesign efforts estimation.

SOLUTION

For the system to support real-time AI-based defect detection within a device, it required a more capacious hardware platform. We selected the Nvidia Jetson board as a performative and cost-effective solution as it maintained all the prescribed functionality, such as video capturing and analysis at high speeds, light and sound signalization, and speed and contrast measurement.

To assess the AI performance on the edge, and prepare a complete estimation of redesign efforts, our team performed:

-

1. A purchase of Nvidia development board & environment setup

-

2. Preliminary firmware source code migration from the initial solution

-

3. Work Breakdown Structure creation

-

4. Main components selection

For the client to avoid additional efforts and molding expenses, we selected the optimal ready-made enclosure requiring minimum modifications.

While estimating, PSA foresaw possible bottlenecks and made adjustments regarding:

-

1. Maintaining image quality without sacrificing speed

-

2. Optimization of memory usage for the accelerated video recording

-

3. Device protection against external objects

-

4. Power consumption, thermal regime, and powering

-

5. Alarm features, lighting control, and camera placement

-

6. Licensing issues

-

7. Additional visual standards support

Thus, the client gained a description of an elegant defect detection solution with server-free AI operation, which significantly unloads industrial networks. Also, the redesigned solution would simplify mounting and allow for avoiding errors during data transfer.

A complete documentation packet includes a project plan and risk plan, a quote with future project estimation, an architecture description, and product cost estimation.

DEVELOPMENT INCLUDED

- 1. Board procurement

- 2. Architecture design

- 3. Firmware migration

- 4. Components selection

- 5. Documentation creation

RESULTS

- 1. A complete assessment of product transfer efforts

- 2. The project on the product transfer is about to start

TECHNOLOGY BREAKDOWN

Technologies

- USB

Platform

- 1. ARM

- 2. Linux

- 3. Embedded

Industry

- Manufacturing

Project size

- 2 SW Engineers

Duration

- 4 months

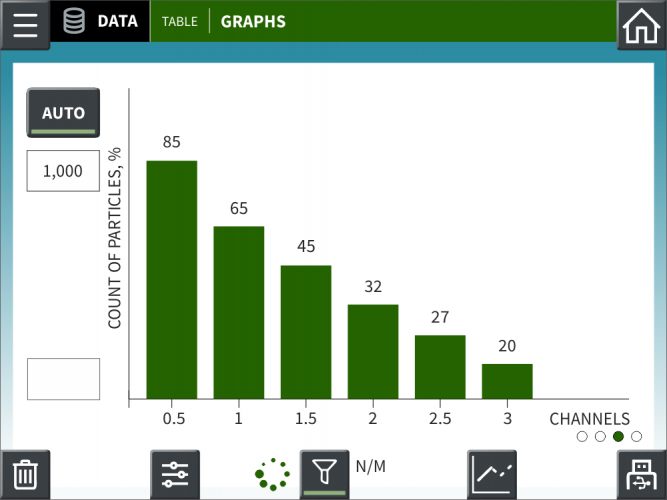

Particle Counting Device Upgrades

HIGHLIGHTS

After years of successful PSA support of particle counting devices designed for cleanroom monitoring, the client contracted us for the development of its new generation. The main focus was on meeting the criteria of the modern world in terms of usability, functionality, and data integrity. Being a high-precision measurement tool, any enhancement for the device has to be done in view of its major requirements – to ensure the appropriate responsiveness and stability to work 24/7.

CHALLENGE

Client Challenge

Release the next generation of the particle measurement instrument to meet the advanced market demands.

Project Objective

Extend functionality and upgrade UI of particle counter to provide intuitive and reliable operations control in compliance with high precision measurement requirements and data integrity standards.

SOLUTIONS

For the device to meet the requirements of the modern world, PSA designed a complex firmware to control operations for the new generation of particle counting device. Based on Qt, the upgraded UI allows for the following opportunities:

1. Set sampling parameters, and execute sampling

2. See the actual state, configure the device, and run self-tests

3. Generate, save in PDF, and print reports

4. View & manage alarms, locations, and recipes

5. Control operations both locally and remotely due to USB, Wi-Fi, and Ethernet support

6. Choose language from 14 options

For the device to comply with standards for certification, we contributed to data integrity demands. 3-step access & NFC-based login were implemented to enhance security, whereas the opportunity to view up to 30k logs was to verify that data had not been changed.

Starting from prototyping and moving through development, we implemented the new UI concept for simple air sampling management, and intuitive training using modern interfaces. We updated all UI elements and widgets, created mockups and user stories, and adjusted the interface to fit the new functionality. The device gained improved navigation capabilities, and a more intuitive look and behavior of the new screens and widgets.

To enhance usability, the PSA team implemented HMI both for:

1. The device with built-in display to provide portable particle measurement in the field

2. Web app for remote operation, continuous monitoring, and updates of devices

For the system to meet responsiveness requirements, we linked the interface with RTOS, defining the optimal way of data exchange to minimize latencies and optimize memory and CPU performance.

At the final stage, PSA engineers performed Acceptance Testing onsite. We ensured the complete operability of the modernized device and conducted training for the client’s development team in case of further modification to the source code within the components.

As a result, the client gained a more functional, secure, and user-friendly device with extended access opportunities, ready to be launched to market.

DEVELOPMENT INCLUDED

1. Requirements definition

2. HMI proof-of-concept

3. Architecture design

4. Specifications development

5. UI implementation

6. Software development

7. Qt optimizations

8. Quality assurance (onsite)

RESULTS

1. The new generation of the device has been launched to the market

2. International cleanroom certification standards meet

3. Reduction of human errors when using

TECHNOLOGY BREAKDOWN

Technologies

1. HTML/DHTML

2. JavaScript

3. Angular

4. .NET

5. C/C++

Platform

Embedded

Industry

Environment

Project size

4.5 people

Duration

5 years

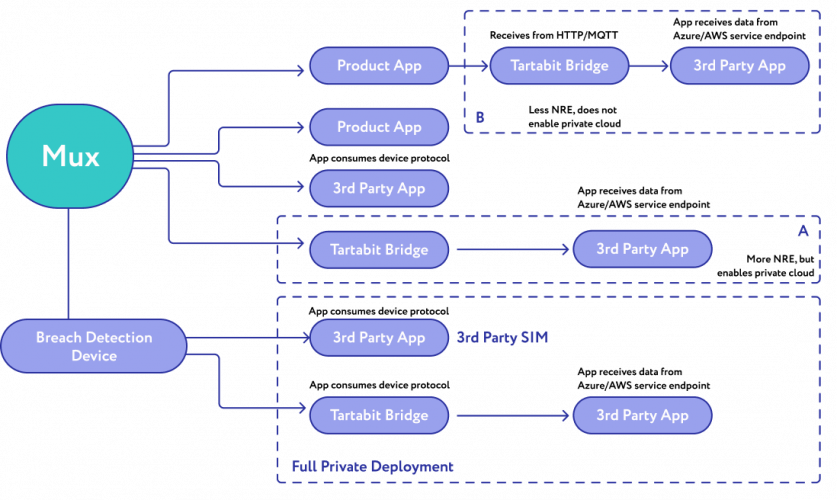

Simplified Deployment of Shipping Container Monitoring Product

HIGHLIGHTS

In 2022, the PSA team took over the development of a shipping container monitoring product, and started enhancing it with new features. Leveraging the potential of integrated IoT infrastructure, our client is focused on further facilitation of the device deployment while strengthening data integrity and performance. To ensure maximized benefits, we provide flexible opportunities for the client to try out new ideas without breaking the budget.

CHALLENGE

Client Challenge

Cost-effectively evaluate the possibility to facilitate product deployment and integration within multiple servers.

Project Objective

With limited resources, deliver PoC of the solution to simplifying data transfer from breach detection devices to multiple servers while maintaining data integrity.

SOLUTION

To evaluate the concept, the PSA team created an MVP of a multiplexor (mux) – an app for transferring complete data from breach detection devices to a number of servers using the server communication protocol.

First, we modified the existing product architecture in Azure by fitting the mux there. Our engineers provided several connectivity options considering a more expensive option with private cloud enablement, and a less expensive option with no private cloud deployment. The app allows for seamless connection to:

1. The product app for shipping monitoring

2. 3-party system directly

3. 3-party system utilizing IoT Tartabit bridge as a mediator to simplify integration.

Second, our team developed an app with limited functionality, which allowed for the thorough evaluation of the basic concept. The solution works with the existing stateful and sequential TCP service, providing data tracking, quick data retransmission for better performance, and data retention in case of failure.

The delivered app contributes to data integrity by utilizing the unified protocol, and allows for facilitation of the deployment by excluding the need for unique provisioning in every device to particular server.

The client rapidly evaluated the PoC and leveraged it for investigation and testing of integration capabilities.

DEVELOPMENT INCLUDED

1.Requirements development

2. Infrastructure set-up

3. Architecture design

4. Software development

5. Functional testing

RESULTS

1. Time and money saved on concept evaluation

2. The app was considered to be utilized for investigation purposes

TECHNOLOGY BREAKDOWN

Technologies

1. Azure DevOps Server

2. TCP/IP

3. .NET

Platform

Server

Industry

Logistics

Project size

1 Software Engineer

1 DevOps Engineer

2 QA Engineers

Duration

4 months.

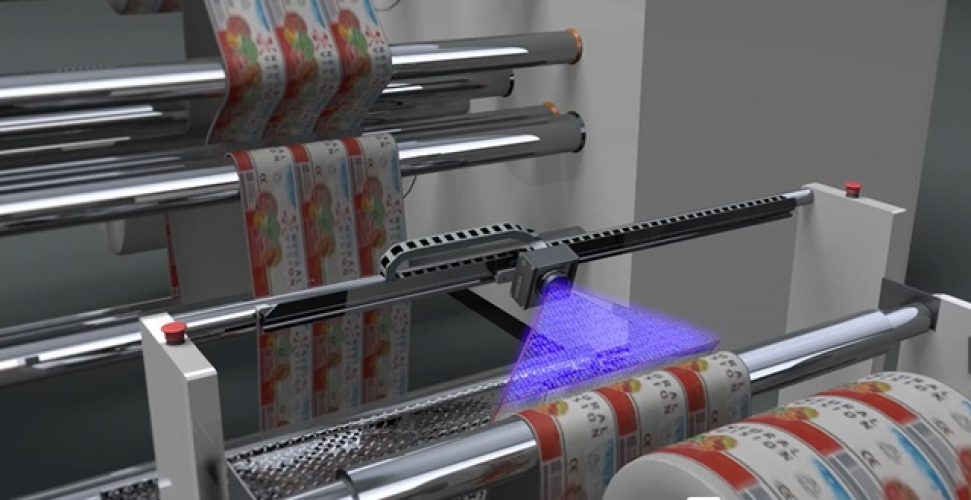

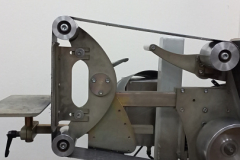

Defect Detection Product Manufacturing Support

HIGHLIGHTS

Our client, a recently founded company, is working to establish itself as a top developer of machine vision products for production quality control. Enlisting the assistance of PSA, the company has developed a cutting-edge defect detection system leveraging neural networks for use in printing houses. Suffering a lack of relevant expertise, they asked PSA for additional support through the product manufacturing phase.

CHALLENGE

Client Challenge

Finalize product prototype to prepare it for certification and further mass production.

Project Objective

Establish the end-to-end manufacturing process for 10 samples of the defect detection device to be used for trial operation.

SOLUTION

Having moved past the development stage of the Defect Detection Product, PSA prepared the foundational framework for all samples to be seamlessly manufactured. Our technical & management support included the following activities:

1. Components procurement based on the initial BOM, including processor modules and long lead components

2. Logistics management. Transferring the components to the manufacturing site

3. Documentation updates for production, defining errors and missing components

4. PCB assembly support, providing components’ replacement when missing

5. Final samples bring-up. Addition and adjustment of the light sources for the client’s needs

As an output, our client received 10 prototypes of the defect detection device to be used within the machine vision system at printing facilities. It allowed the client to launch their trial operation to maximize product potential, identify flaws, and create a strategy for further development.

DEVELOPMENT INCLUDED

1. Components Selection & Procurement

2. Documentation Updates

3. Assembly Support

4. Assembly Support Improvements implementation.

RESULTS

1. Production and delivery of prototypes

2. Final BOM validated

3. Time and money saved on updates

4. Commencement of trial operation

TECHNOLOGY BREAKDOWN

Technologies

1. Jira

2. JavaScript

3. Python

4. C/C++

Platform

Embedded

Industry

Manufacturing

Project size

5 Software Engineers

Duration

16 months

FURTHER COOPERATION

Alongside our client, PSA is continuing work on further product development, evaluating the neural network's performance deployed in the device itself.

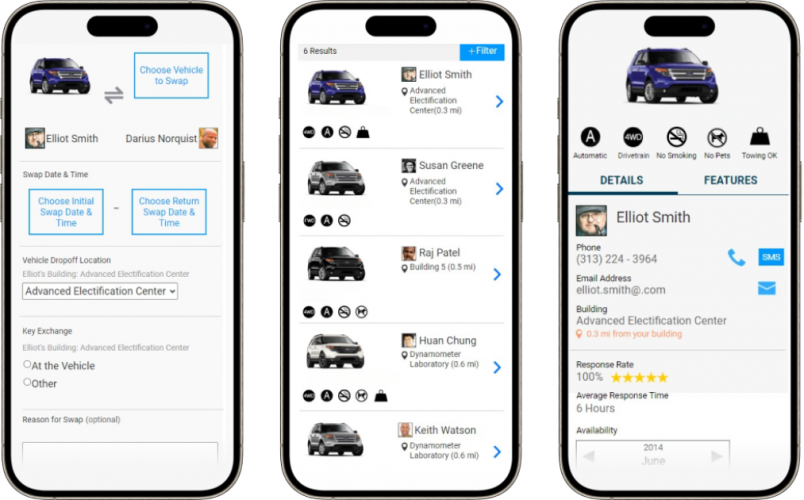

Car Sharing App

HIGHLIGHTS

Our client, a provider of internet audio products owned by a major automotive manufacturer, came to PSA with a request to develop a user-friendly car sharing app for corporate use. At the dawn of shared mobility, the client intended to perform a market test to investigate the sociology of car swapping and decide whether to invest in developing a similar service for public use.

CHALLENGE

Client Challenge

Run a pilot car sharing program in a controlled environment to assess the experience of swapping services.

Project Objective

Develop a multi-platform car sharing app for corporate use while considering frequently changing requirements.

SOLUTION

In tight cooperation with the client, we created a peer-to-peer (P2P) car sharing application, providing a convenient platform for swapping cars between the company’s employees for the short and long term.

Running on Android, iOS, and Web platforms, the app provides the following functionality:

- 1. Register, log in, and set up user profiles

- 2. Select car by model, fuel, drive, and transmission type, personalized vehicle restrictions setting (ie. smoking, transporting pets, etc.),

- 3. Browse the history and schedule of availability, request, book, and confirm cars

- 4. Add vehicles to the pool

- 5. See the owner’s contact information

- 6. Get notifications of time starts and finishes

- 7. Document the condition of the car before and after the exchange

The PSA team performed the core development activities in parallel with the server backend and app interface design development on the client’s side. We structured the client’s concept by creating a use cases diagram and app architecture then defining requirements for interfaces, global types and structures within the software, and event processing. During development, we reviewed designs from the client’s side and performed testing and bug fixing, demonstrating strong collaboration.

Aimed at investigation, the project has undergone 8 changes during development. We shared the client’s goals and have been adaptable to the project needs through conducting additional research, promptly reassessing terms, and re-calculating budget when needed. Thus, for instance, IE support and Facebook SDK were included in the app.

As a result, the client gained a simple and user-friendly car sharing application available on smartphones, tablets, and via the web. We also provided knowledge and technology transfer for the client’s team to refine and further develop the app internally.

DEVELOPMENT INCLUDED

- 1. Requirements clarification

- 2. Architecture design

- 3. Software development

- 4. Interface design review

- 5. Project change requests implementation

- 6. Testing & debugging

- 7. Documentation creation.

RESULTS

-

1. Car sharing app completed

-

2. Market test run, and the required data was collected

TECHNOLOGY BREAKDOWN

Technologies

- 1. Angular

- 2. Objective C

Platform

- 1. iOS

- 2. Android

- 3. Java

- 4. Web

Project Size

- 2.5 people

Duration

- 19 months

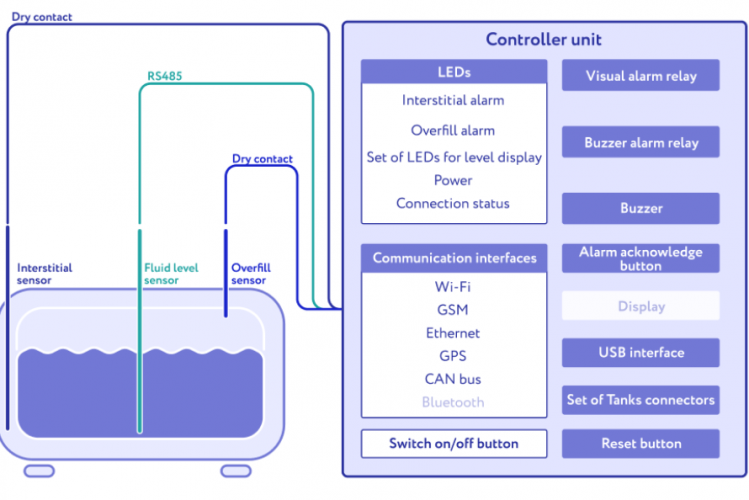

Fuel Tank Monitoring System

HIGHLIGHTS

PSA were contacted by a provider of comprehensive IoT solutions and products for fleet and fuel management. They had a vision of a new product for smart control of tank status and fluid level within, which would be appropriate for commercial scale. The main vector for them was to minimize production costs by leveraging ready-made components.

CHALLENGE

Client Challenge

Create a low-cost product for remote control of tank fuel level.

Project Objective

Create the complete initial design for the fuel level monitoring system considering the tight production budget.

SOLUTION

The PSA team architectured a comprehensive hardware system for seamless remote detection of fuel levels in tanks. Сonsisting of sensors, a control unit, and solar batteries, the system is designed to provide reliable and cost-effective usage for both resting and mobile fuel tanks.

The following system features were incorporated:

-

1. Sensing of fluid level, overfilling of the tank, and fuel leakages

-

2. Audial and visual alarm notifications

-

3. LED-display for fuel level, power, and connection status

-

4. Communication with server via Wi-Fi, 3G and GPRS

-

5. Switch on/off and reset buttons

-

6. Simultaneous monitoring of up to 8 tanks by 1 control unit

For this project, the PSA team created a detailed system description, including its architecture, assembly guide, components requirements, product use cases, and all the functional and non-functional requirements for the system. This allows the client to proceed with seamless design, prototyping, and further manufacturing.

To support the low-cost design of the tank monitoring system, we conducted detailed market research and selected affordable and weather-resistant off-the-shelf components that require minimal adjustment to have the system completed. These components include:

-

1. Industrial-grade computer module based on Raspberry Pi

-

2. Communications board with US band 4G/LTE, GPS, and Wi-Fi

-

3. Enclosure

-

4. Battery

-

5. Solar panels

-

6. Equipment for mounting entire system with solar panels on a tank

In addition to the list of components with their possible design, PSA estimated the product implementation for 2k Fuel Tank Monitoring System units, including its design, prototypes, and production cost.

As a result, the client got all the documentation required for further product development and production without technical and financial risks. The system contains all the components for management via the web, desktop, or mobile app.

DEVELOPMENT INCLUDED

1. Market research

2. Requirements definition

3. Architecture design

4. Product specification creation

5. Components selection

RESULTS

1. System ready for development and manufacturing

2. Technical and financial risks are minimized

TECHNOLOGY BREAKDOWN

Platform

Embedded

Industry

1. Energy

2. Transportation

Project Size

6 People

Duration

1.5 months

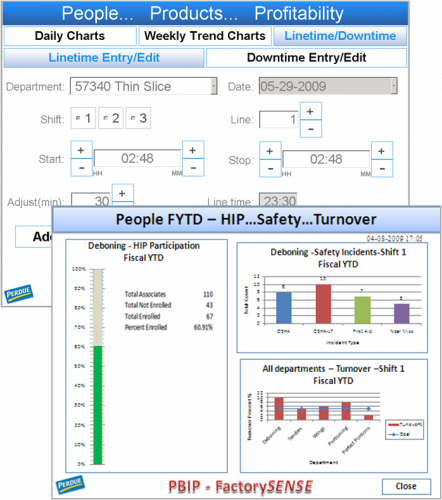

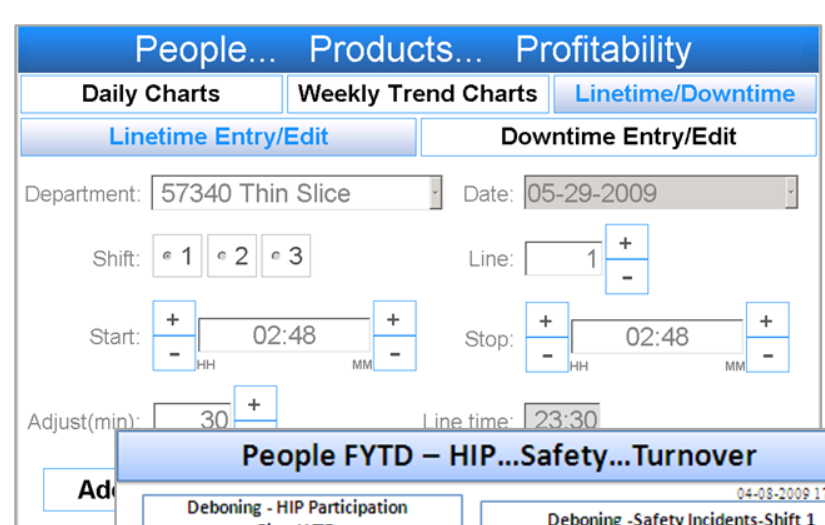

Customized Analytics for Business Process Improvement

HIGHLIGHTS

We were contacted by a leading food and agricultural company with global retail brand recognition. They intended to enhance the poultry production process by utilizing advanced analytics.

CHALLENGE

Customer Challenge

Improve business processes for poultry deboning and portioning departments.

Project Objective

Keep the client fully informed about business and production processes for poultry deboning and portioning.

SOLUTION

To have an opportunity to optimize processes, the client needed to have all relevant information on what’s going on in the enterprise. To provide this, we designed and developed a desktop application that automatically collects, stores, and analyzes the data from the production line for deboning and portioning, as well as relevant enterprise files.

The delivered app allowed the client to monitor:

-

1. Yield

-

2. Faulty production

-

3. Safety incidents

-

4. Staff turnover

For the app to be used by quality engineers, enterprise analysts, and other interested staff, each user category was granted specific access rights. They can download the app to their devices and are authorized by login and password. The GUI of the app supports a touch screen as well.

For the convenient monitoring of business processes, the app provides the following:

-

1. Generating and displaying reports in the form of charts

-

2. Printing the created reports

-

3. Search for selected data records

-

4. Input, modification, or deletion of the data records

Thus, the application allows the client to monitor productivity and efficiency indexes on a daily and weekly basis.

DEVELOPMENT INCLUDED

- 1. Requirements definition

- 2. System architecture and design

- 3. Application development

- 4. Custom User Interface development

- 5. Functional testing

- 6. User Guide creation

RESULT

-

1. Labor cost reduced by 50%

-

2. 70% less complaints on products quality

-

3. Profit increased by 10%

TECHNOLOGY BREAKDOWN

Technologies

- 1. Seapine TestTrack

- 2. SQL

- 3. .NET

- 4. C#

Platform

- Windows

Industry

- 1. Foodtech

- 2. Manufacturing

Project size

- 2 people

Duration

- 4 months

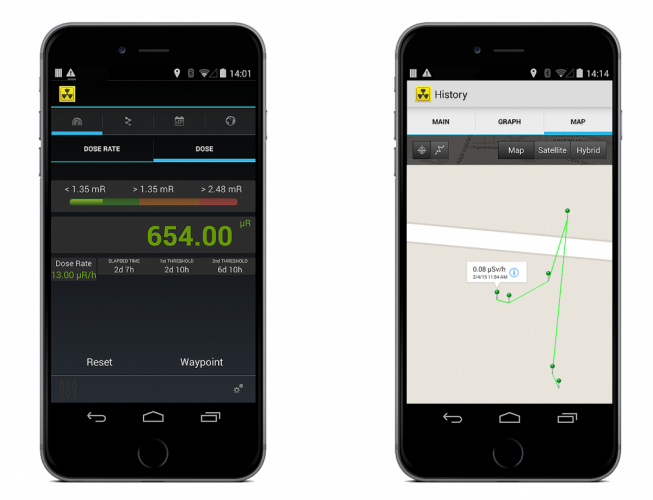

Radiation Detection Tracking Application

SCOPE OF WORK

To develop a mobile application for Android 4.3 platform to display the results of measurements received from a personal dosimeter via Bluetooth 4.0 (BLE)

TECHNOLOGIES

- 1. Java

- 2. Android SDK

- 3. Bluetooth 4.0 (BLE)

- 4. XML

- 5. SqLite DB

- 6. JSON

- 7. Google maps API

- 8. Axure

TASKS

- 1. Requirements Definition

- 2. GUI Design

- 3. Mobile Application Development

- 4. Functional, System and Integration Testing

PROJECT SIZE

- 4 person project

- 6 month duration

- Turnkey Development

Bootloader Integration Project

SCOPE OF WORK

Implementation of Bootloader for Atmel SAM D20 MCU to be used on a custom PCB with i.MX module, responsible for FW updates for both Atmel and i.MX FW.

TASKS

- 1. Develop Bootloader FW which performs the Application Update and Bootloader Update process

- 2. Provide API Healthcare with documentation for deploying, running and rebuilding developed FW

- 3. Integrate the new code into the current FW

- 4. Test the Bootloader on provided hardware

TECHNOLOGIES

- 1. C

- 2. Python

- 3. FreeRTOS

- 4. Linux

- 5. Atmel ATSAMD20 MCU

- 6. Atmel studio 7.0

PROJECT SIZE

- 1 employee

- 2 months duration.

Dosimeter Calibration Management Tool

HIGHLIGHTS

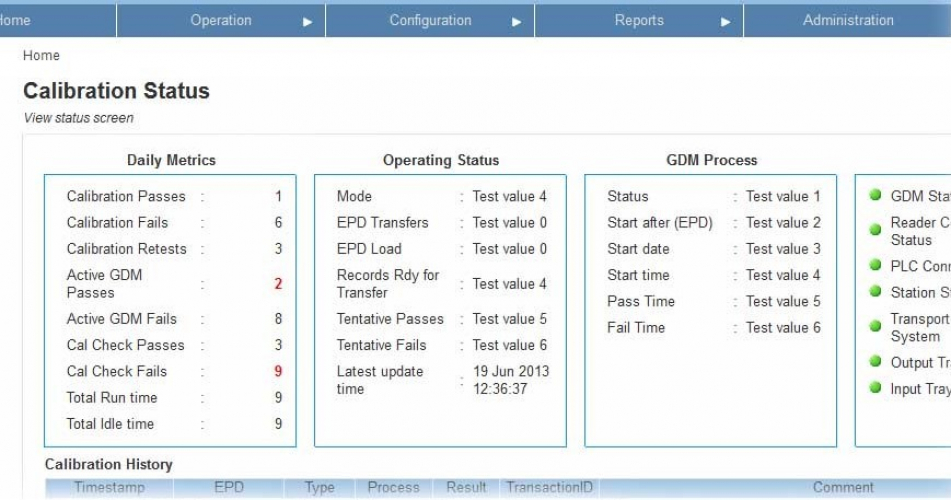

Our client – a globally represented supplier of scientific instrumentation – involved PSA in their efforts to optimize the dosimeter calibration process that is executed using a range of radiation sources. Intending to launch a new generation of personal handheld dosimeters, they augmented the calibration equipment with a new device compatible with both existing and upcoming models of dosimeters. The crucial step of this optimization was to provide an opportunity for real-time remote monitoring and control of the whole calibration process for all types of dosimeters, including configuration, opening of the radiation source, and the transportation of dosimeters between irradiation stations.

CHALLENGE

Client Challenge

Reduce the costs for calibration of personal handheld dosimeters considering the launch of the new model.

Project Objective

Ensure precise and convenient calibration for multiple types of dosimeters while also increasing process performance.

SOLUTION

To provide comprehensive management of the dosimeter calibration processes, the PSA team developed desktop and web tools that allow for control of the augmented calibrating machine. In real-time, the application collects and sends data to dosimeters under calibration, the transportation system of the calibrating machine, and the irradiation source module, which contributes to the following functionality:

-

1. Radiation dose management for the particular types of dosimeter; open/close status for exposure source.

-

2. Establishment of position for dosimeters, and their moving between irradiation stations at the required direction

-

3. Adjustment of dosimeters’ settings in accordance with their response to exposure.

-

4. Delivery of calibration reports and provision of secure automatic data export to the centralized production management system

-

5. Studying the history of dosimeters calibration configuration, process, and results.

The PSA team designed the application from scratch starting with the complex architecture design, followed by implementing algorithms for dosimeters calibration, developing UI, and conducting onsite testing. During the project, we utilized real client dosimeters and IR readers, simulating doses and detector counts, and the imitation of the robotic system that transports the dosimeters between irradiation stations.

To ensure performance is maintained in terms of data size increases, we connected the app to an SQL server. Also, our team implemented multi-tasking for the updated calibrating machine, which allows for simultaneous irradiation of several dosimeters. These features together with a responsive UI contributed to the ultimate performance and throughput of the system.

As a result, the threshold and sensitivity of the various types of client-produced dosimeters are set in adherence with the instructions of the PSA-delivered app. The client receives calibration verification, analysis, and reporting for every produced dosimeter, which helps verify the devices before sale. The high accuracy of calibration allows for the usage of personal handheld dosimeters for scientific, industrial, medical, and other purposes.

DEVELOPMENT INCLUDED

- 1. Requirements definition

- 2. Architecture design

- 3. Software development

- 4. Algorithms implementation

- 5. GUI development

- 6. Functional testing

- 7. Integration & site acceptance testing

- 8. User and maintenance guide creation

RESULT

-

1. Productivity has doubled

-

2. Calibration costs have been reduced

-

3. Extendable to include future models

TECHNOLOGY BREAKDOWN

Technology

- 1. SQL

- 2. .NET

- 3. C#

Platform

- 1. Web

- 2. Desktop

Industry

- Environment

Project size

- 2.5 people

Duration

- 19 months

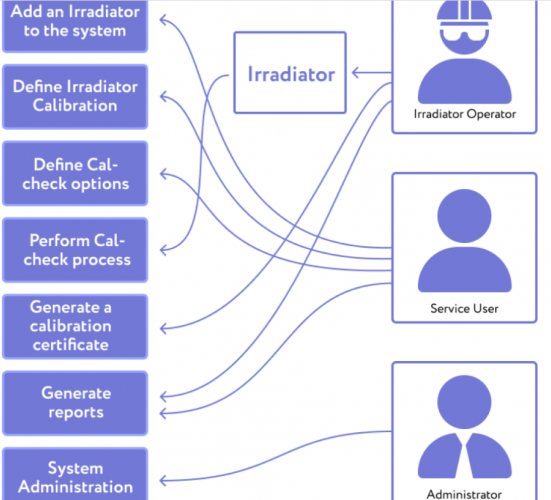

Dosimeters Calibration Check System

HIGHLIGHTS

After the successful delivery of a number of projects, we continued cooperation with our client, a leading manufacturer and supplier of scientific radiation measurement equipment. For certification purposes, Electronic Personal Dosimeters (EPDs) have to be checked annually and calibrated if necessary. To perform calibration checks for dosimeters, the client needed a flexible and scalable tool that could interact with all the 3rd party irradiators used for this purpose.

CHALLENGE

Client Challenge

Simplify the process of issuing certificates for the multiple types of EPDs, including models currently in development.

Project Objective

Expand the functionality of the calibration-check system to ensure simple annual verification for various types of dosimeters, which allows for adding new devices and remote access.

SOLUTION

To ensure rapid and reliable dosimeter calibration checks, the PSA team developed a software solution that interacts with irradiators to perform these checks in real-time. It acts as a central repository for the EPD calibration and related data, providing an external interface to the calibrating system. The application allows for the following actions:

- 1. Choose a procedure for the calibration check from the list

- 2. Get procedure configuration parameters

- 3. Verify calibration check results for each EPD

- 4. Receive and print reports

- 5. Manage users, lists of irradiators, procedures, EPDs, and calibration check results

During the project, the PSA team solved the issue of scalability, thus allowing the delivered software to interact with the legacy, new, and prospective generations and types of dosimeters launched by our client and 3rd party irradiators. To promote scalability, we ensured the calibration check configurations include facultative elements that can run only if they are defined in the database.

Thus, the PSA-designed interface allows for:

- 1. Adjustment to capabilities of various irradiators, including various sources, dose rates, capacity, throughput, and levels of automation

- 2. Adjustment to the more advanced EPD concepts such as detector counter readings, detector gains, and partial doses

- 3. Compliance with application-dependant technical recommendations

- 4. Addressing specific issues that a customer might face.

For the third-party irradiators to be seamlessly connected, we created APIs for the calibrating system. We simplified the integration process by utilizing the simulators for the maintenance database system and irradiators.

We provided the client with all the necessary documentation for the system to be easily installed at any location globally. The documentation includes a User Guide, Administrator Guide, Deployment Guide, and Engineering Interface Specification.

DEVELOPMENT INCLUDED

- 1. Onsite requirements definition

- 2. Software design

- 3. API implementation

- 4. Database implementation

- 5. Web application implementation

- 6. UI development

- 7. Documentation creation

- 8. Functional testing

- 9. Acceptance testing

RESULTS

-

1. Calibration-checks are available for future generations of dosimeters with the use of various types of irradiators

-

2. Dosimeter verifications are performed faster

TECHNOLOGY BREAKDOWN

Technologies

- 1. XML

- 2. Angular

- 3. SQL

- 4. NET

- 5. C#

Platform

- 1. Web

Industry

- 1. Radiology

- 2. Environment

- 3. Applied Science

- 4. EIoT

Project size

- 2.5 people

Duration

- 13 months

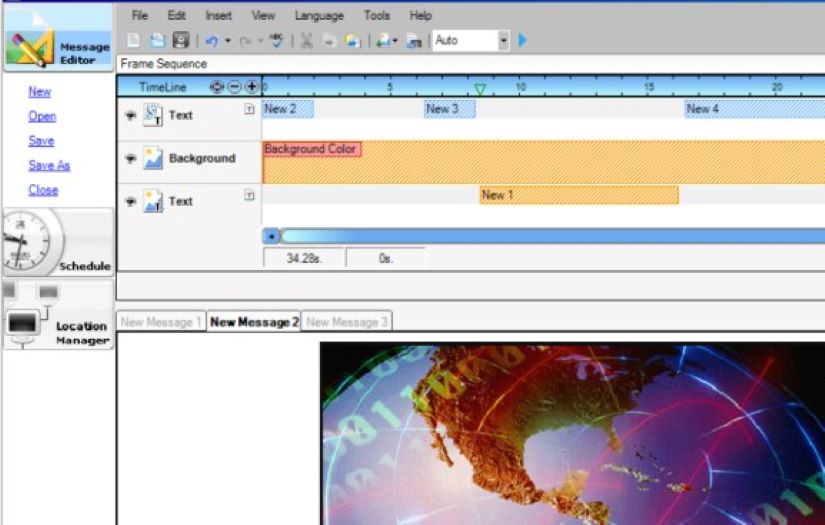

Ooh! Media Application and Sign Player

HIGHLIGHTS

Adaptive Micro Systems LLC is a cutting-edge Milwaukee based manufacturer of indoor and outdoor LED displays offering LED signage systems installed across the entire US and globally. They needed a software that enabled the Adaptive signs to control animations, motion backgrounds, and messages.

CHALLENGE

PSA recognized the potential for success in manufacturing modern software for the advertising industry. The goal was to create a system (a desktop application and sign player) able to set, schedule, and deliver rich media content that is seamlessly built into an LED billboard display which is “durable enough to stand up to years of harsh weather and demanding industrial environments, and deliver important visual information 2X brighter than any other electronic signage options.” We had to create an innovative media LED message software that is intuitive and efficient.

SOLUTION

After a comprehensive assessment of the project, we established a team of developers. With close collaboration they developed a high-quality system to satisfy the request of the client. The solution delivered by our team included the Ooh!Media desktop application for digital media content management and the ooh!Media Sign Player for rendering digital content.

One of the features we introduced within this project was the option of setting a schedule for displaying the message on a LED sign. The system supported video, images, and TrueType fonts capable of displaying the RSS information from the Internet. The custom UI was specially designed and developed for the ooh!Media app.

DEVELOPMENT INCLUDED

- 1. Software development (desktop applications).

- 2. Software localization (desktop applications).

TECHNOLOGY BREAKDOWN

Technologies

- 1. XML

- 2. XSL

- 3 .NET

- 4. C#

- 5. C/C++

Platform

- 1. X86 32-bit

- 2. X86 64-bit

- 3. ARM

- 4. Windows

- 5. Windows CE

- 6. Embedded

- 7. Desktop

Industry

- 1. Entertainment

- 2. Industrial

- 3. EIoT

Project size

- 4 Team Members

Duration

- 10 Months

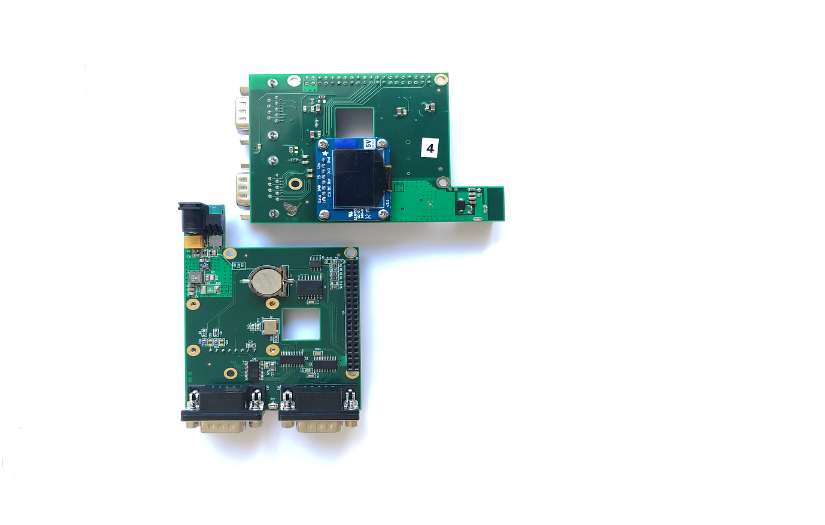

Placement Platform Design with Raspberry Pi

HIGHLIGHTS

In 2019 PSA delivered a board design - Raspberry Pi Serial Hat Platform (RPSHP) - for Palatiumcare Inc, an American leader in senior healthcare assistance. The entire scope of work consisted of two parts: platform prototype implementation and further update.

CHALLENGE

The primary objective of the Raspberry Pi project was to design a placement platform for the Netburner and Nano that would fit into a case with the existing X and Y footprint while also utilizing the original platform ports and inputs.

In order to provide enhanced technical functionalities, PSA engineers had to design an expansion card that connects to the Raspberry Pi 3 single-board computer via a 40-pin GPIO connector containing all of the following:

- 1. 2 additional RS-232 serial ports

- 2. Real-time clock

- 3. FRAM memory with SPI interface

- 4. Reset switch for configuration parameters

- 5. Miniature screen with I2C interface to display configuration information

- 6. Create a minimally modified case to fit the board according to specific measurements

Other technical specifications provided were as follows:

- 1. Support for additional devices in the Raspbian operating system image

- 2. Support for the new Netburner configuration utility device

- 3. Modifications to the device case for outputting additional interface connectors

- 4. Reset switch for configuration and display

SOLUTION

To resolve technical issues, PSA specialists designed the entire device, including the electrical schematic diagram and layout of the expansion board. They also selected and purchased components for the assembly and delivery of 5 prototypes. The newly modified operating system of the device contained the necessary drivers and software modules to support additional new devices.

DEVELOPMENT INCLUDED

- 1. Components selection and specifications review

- 2. Electrical circuit diagram design

- 3. PCB layout design

- 4. Mechanical design for enclosure and 3D modeling and 2D drawing creation

- 5. Prototyping and testing

- 6. Prototypes validation and design adjustments

TECHNOLOGY BREAKDOWN

Technologies

- 1. PCB CAD

- 2. TCP/IP

- 3. Python

- 4. C/C++

Platform

- 1. Raspberry Pi

- 2. Linux

- 3. Embedded

Industry

- 1. Healthcare

- 2. EIoT

Project size

- 9 Team Members

Duration

- 8 Months

Dosimeter Mobile Application

HIGHLIGHTS

Polimaster, a manufacturer of radiation measurement & detection instruments with a global presence in over 55 countries, approached PSA with a project requiring the development of an Android mobile application for a dosimeter.

CHALLENGE

The project was to develop an Android mobile application that would communicate with a wide list of dosimeters over Bluetooth.

The resulting application had to be able to receive and display real-time measurement data, store history and upload measured data onto NPNET or RadResponder servers, show tracking on Google Maps (GPS, mobile network), and share data over social networks (Facebook, Twitter).

SOLUTION

The PSA team performed design, development and testing of a mobile application on Android 4.3+ platforms to display the data received from a personal handheld dosimeter via Bluetooth 4.0 (BLE) protocol with a variety of personal dosimeters.