Manufacturing, the most critical function for product goods companies, has seen a sea change of functioning and optimization over the last five decades. Modern-day production has seen demands from customers vary between product mixes to Just-in-time delivery of goods. The entire process of producing goods has become challenging - primarily because of the plethora of product mixes the company has to deliver on. Such systematic and complementary execution of production is growing to be a challenge. And this is where Product Scheduling comes into play.

A major reason for the goods to be delivered to a customer in time and without defects is the use of production scheduling software and techniques. No industry today can live without best-in-class production scheduling systems. It’s become a backbone for strong manufacturing over the technological evolution the industry has faced in the last two decades.

Goodfirms here lists out 8 of the Best Free and Open Source Production Scheduling Software, to help prospective organizations seek out an ideal fit for their manufacturing needs. The intention is to ensure that all characteristics, advantages, and benefits of the software category are covered in the blog.

What is Production Scheduling?

Production Scheduling is the planning and controlling of the manufacturing process through the effective allocation of resources (human and machinery), raw materials, as well as concurrent and incident processes.

The most important components of this process are as follows -

- Planning and Procurement - Raw materials requirements for the process must be procured using correct channels and in accurate amounts. Planning of resource usage, Calculation of raw material requirements, and daily output must be done to ensure customers receive goods on time.

- Scheduling - The order of process flow with respect to time and date, and goods produced, is called scheduling. Companies often refer to a master schedule, a complete plan for key resources to utilize time on raw materials to be constructed into goods.

Other important factors considered are the routing of raw materials through specific processes to complete production and dispatch

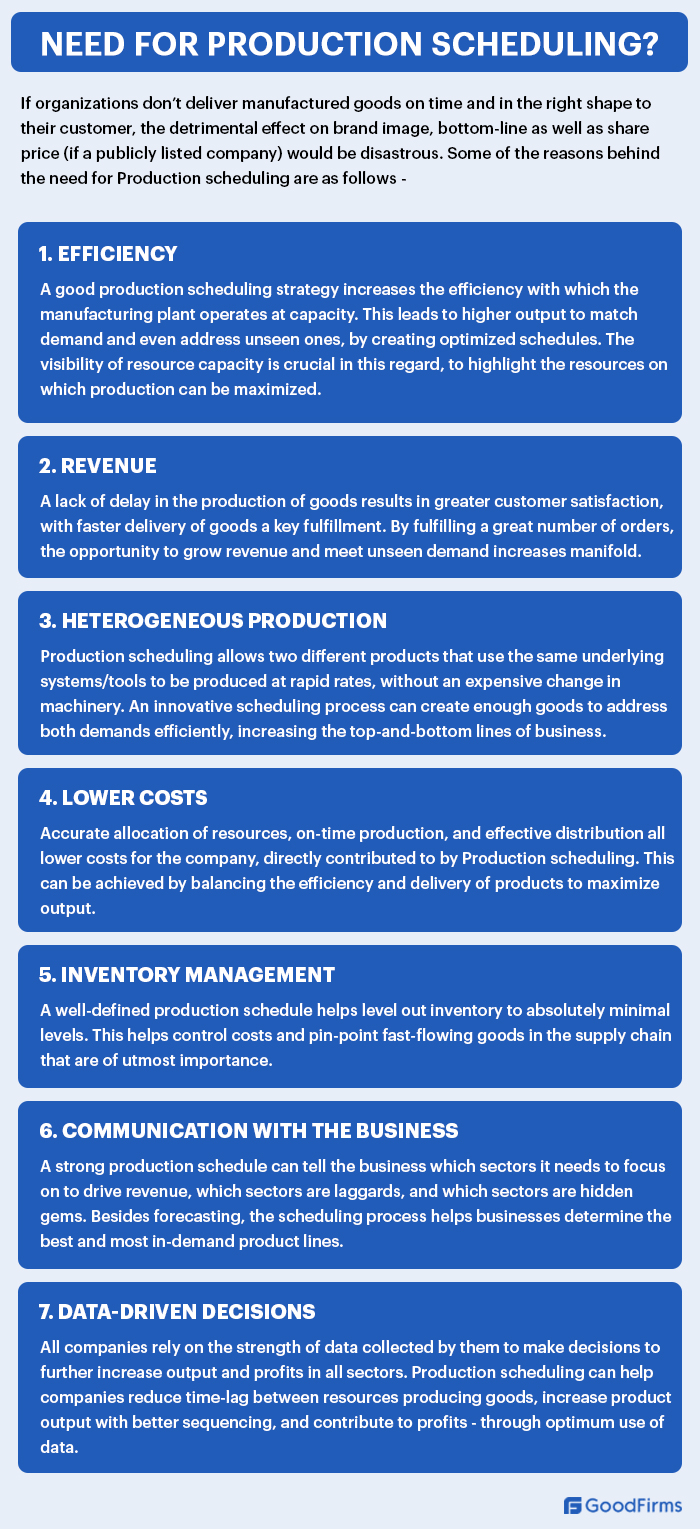

Need for Production Scheduling

How does better Production Scheduling lead to a healthier bottom-line for the organization?

Have you ever heard of an organization heading into a market for production goods without a fixed scheduling plan in its manufacturing plant? Such scattergun approaches are rarely successful for businesses.

Production scheduling helps businesses match demand forecasts and actual supply of goods. This results in better management of the raw materials and different kinds of resources used, which results in cost saving. Resources can also be effectively assigned and utilized during the production process to increase productivity, which results in double the output for the same level of input.

Alongside the above, controlling inventory flow is also important. Storage expenses form a solid component of a company’s outflow and with better production scheduling, easing the inventory to match outflow of goods reduces company lag on the balance sheet and improves the inventory turnover ratio.

Great production scheduling also helps draw up maps of business plan optimization. With a multi-pronged approach to production, organizations can use the same approach to set up manufacturing of different goods, for different markets, under different price points. Lesser the input cost, but greater the addressing of demand, which leads to higher profits.

Producing goods for export is another key variable here. Ensuring effectively higher production of goods for foreign transport will help companies double down on revenue. Production scheduling also removes many inaccuracies of production - such as ineffective time allocation and poor process flows - giving way to refined goods which will spur demand.

All the processes mentioned above play a great role in businesses increasing their bottom-line.

Key challenges faced in Production Scheduling:

Every process scheduling task is filled with the danger of mismanagement and creeping inefficiency. Besides the above, some of the biggest risks that cancel out the advantages of a production scheduling process are as follows -

- Poor Communication - Insufficient coordination between different manufacturing departments could endanger a production schedule, no matter how well the system is working.

- Outdated Software - Several key processes in production scheduling depend on automation and the latest software upgrades to handle processes and loads. Lack of system updates is detrimental.

- Re-planning - Often products/goods waiver in demand or regulations as per authorities. This requires major shifts in production to meet specifications of manufactured goods. This will require the rescheduling of entire processes which is time-consuming and ineffective.

- Raw materials discrepancy - Raw material wastage is a common bane of most manufacturing companies. Every time a good is stuck on the table due to the poor quality of raw materials, the entire production schedule goes for a toss.

- Vendors Distrust - Vendors sometimes cannot meet the demands of a production heavy organization. Be it raw materials or the flow of manpower, vendor inefficiencies throw the spanner into the works.

What are the different Production Scheduling techniques?

Production scheduling techniques are looked through with a fine comb to increase performances of the manufacturing set-up. From processes such as Ichikawa’s diagram to Kanban Cards, the innovation around these processes has been significant. Some of the most important production scheduling techniques are -

Finite and Infinite Capacity Scheduling - Both these types of scheduling consider load capacity on resources and the timeline of delivery of goods.

In a finite capacity scheduling process, the overall load on all resources is calculated and calculations are made on how new production requirements should be adjusted to match the load to create an efficient system. There is no reprioritization of tasks/workload for the due dates.

In an infinite system, every resource is considered to have sufficient capacity to match order dates. The process identifies which resources need additional capacity, those that have the capacity to utilize further, and how many more resources will be needed to fulfill demand. The infinite process then adjusts resources and due dates accordingly.

Backward and Forward Scheduling - These are techniques to determine and estimate production commencement and finishing dates.

Backward scheduling estimates production scheduling capacity and resource utilization needed to fulfill and order based on the end date. The process determines the start date for production-based on, working backward with a fixed load output and schedule.

Forward scheduling is the opposite of backward scheduling. Here, resources allocation, capacity/load distribution, and schedules are determined based on an estimated time the resources are made available. The idea to ensure all order fulfilments by the delivery date.

Just-in-Time (JiT) Scheduling - Last minute changes to the production schedule/requirements are given in any industry. JiT ensures production schedules are adjusted and resources are made available to just ensure the orders are delivered to the client right on the deadline. This is to ensure minimum production wastage and inventory usage.

Evolution of Production Scheduling

Mankind’s quest for maximum production efficiency has been known long since the first industrial plants opened doors to production circa 1760. Production scheduling had been in the cynosure of the earliest foreman and floor managers, but no relative improvement had been made to the system until Fredrik Taylor, the father of industrial efficiency, came along in the 20th century.

Taylorism became popular through his book Principles of Scientific Management, which stated that worker efficiency on tasks could be improved by allotting them work that their skills and capabilities were most aligned with, while supervision should be conducted regularly. In effect, scheduling and planning of work must be done equitably per resource of labor.

Karol Adamiecki and Henry Gantt both made significant contributions to the production scheduling problem. The former created the Harmonogram, which used strips of paper clipped onto a metallic frame, whose one side consisted of markings perspective to the time taken for one operation to complete. The paper strips could be pulled off to represent one entire task being completed.

The latter created the now ubiquitously used Gantt Chart, a modern-day standard for task scheduling across industries. The horizontal bar graph task scheduling method was a revelation during its time. After Gantt, the Program Evaluation Review Technique (PERT) analysis method tried to demystify the scheduling stages. It was a graphical representation of project flow, with the expected time taken at each stage to buff up the manufacturing process.

Then came Johnson’s rule in the latter half of the century. The rule reduced the time taken to complete a job (or group of jobs) based on the availability of two successive workstations or two different work centers. The rule greatly reduced idle-time between two machines and sequenced the tasks for maximum productivity. The rule could also be used for task management between plants at various sites.

Modern-day production scheduling software combines the best of all processes mentioned above to deliver products in a critical time. Production scheduling systems help companies adapt to ever-changing requirements in product demand, getting a variety of goods to consumers in-time.

What is Production Scheduling Software?

Used under the wider ambit of the manufacturing and planning, production scheduling software is a suite of widely used functions that enable the planning, scheduling, manufacturing, and distribution of goods produced in a plant.

Production planning software provides the right platform to track, analyze, and optimize the process of manufacturing with automated scheduling mechanisms, and quality control loops. Several key features such as inventory management, vendor management, and re-scheduling of the process to fit demand are also available.

Overall, production planning software eases out manufacturing constraints arising out of manual processes and ensures load capacity on resources and due dates are in perfect sync.

Features of Production scheduling Software

Advantages of Production Scheduling Software

Who uses Production Scheduling Software?

Good and well designed free production scheduling software is needed by many companies in every industry that deals with the manufacture and supply of produced goods. Industries such as 3D printing, Cardio and Gym equipment manufacturing, and even alcohol production require an exceptionally free and open source production planning software or manufacturing planning tool.

Within companies, the production planner is the go-to person who uses the software for resource allocation and maximizing production efficiency. All personnel on the shop floor have access to functions of the software unless limited by user access protocols. Often, the heads of the manufacturing department also use the software to extract reports on the production capabilities of the plant and further optimization.

Let us now go through the details about the top 8 free and open source production scheduling software.

Top 8 Free and Open Source Production Scheduling Software

1. Frepple

An open source production scheduling software, Frepple’s Software as a Service (SaaS) tool is a simple integration that sits on top of existing Enterprise Resource Planning (ERP) systems. Its planning and scheduling feature sets offer enhancements on traditional ERP functions, without needing largescale changes. FrePPle’s APIs allow it to be hosted on the cloud making it accessible for a variety of businesses ranging from healthcare to FMCG manufacturing.

Specifically targeting mid-size organizations, FrePPle helps evade costly software implementation or unmanageable production worksheets. The production scheduling tool takes less than 12 weeks to implement for businesses, costing less than a six-digit sum.

The Paris-based company has three-tiers in its pricing model, all billed annually. It also offers training and implementation as part of an overall package.

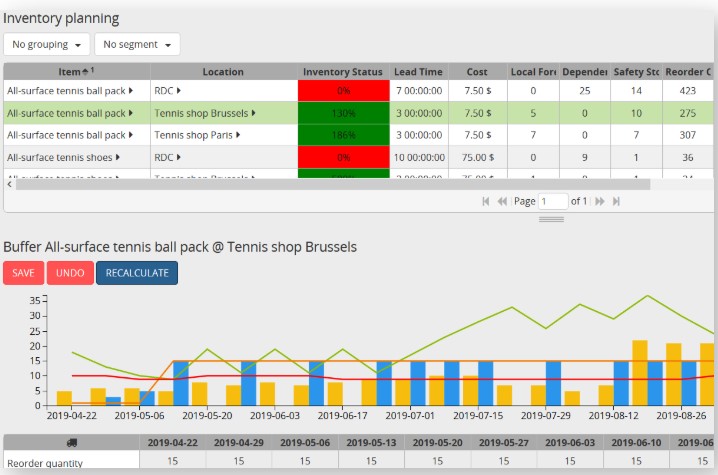

Source - FrePPle

Some of the features of the open source production scheduling software are as follows -

- Reporting dashboard with data visualization tools

- Rescheduling with a drag-and-drop interface for resources

- Predictive delivery date scheduling (Due date quoting)

- Data-Driven MRP (DDMRP)

- Production simulation (What-if Scenario analysis)

- Bottleneck analysis

- Customer prioritization based on order size, demand, and delivery date

- Predictive capacity calculation

- Four modes/techniques of production scheduling

- Heuristic solver algorithm

2. OpenPro

An open source production scheduling software, OpenPro offers a wide range of manufacturing solutions ranging from a master scheduler to an efficient resource planner. Particularly efficient in the long-range planning of manufacturing scheduling, the production planning software has created tools to manage resources and capacity spread over multiple geographies.

The USA-based organization also caters to correlated products such as Electronic Data Interchange (EDI) and Warehouse Management Systems (WMS). It’s Capacity Resource Planning (CRP) arm helps estimate the resources and corresponding load required to fulfill demand. It helps reduce inventory and bottlenecks, driving up efficiency.

Source - Open Pro

Some of the features of this open source production scheduling software are as follows -

- Up to three-year Demand and Purchase forecasting & Planning

- Analytics Reporting Dashboard

- Visualized reporting formats

- MRP Process Tools - BOM, BOP, MFG Calendar, Work Orders

- Inventory Control Centre

- Document Imaging

- Arrangement of products into product families (Groups) to facilitate billing and costing

- Tracking of Payables to vendors

- Web-hosted platform

- Access Control and User Authentication

- Automatic Scheduling

- Track different manufacturing modes such as Make-to-Stock, Make-to-Order, and Assemble-to-Order

3. Axelor

Axelor is an open source production scheduling software that is marketed as an alternative to expensive ERP solution sets, with its characteristics - modularity, innovativeness, and scalability - bearing the hallmarks of a BPM software.

This Production Scheduling App helps users simplify nomenclatures for business process requirements while using a sophisticated calculator tool to help place purchase orders. Axelor quickly calculates resource capacity to prevent production cuts, while tracking the use of raw materials in produced goods and scrap to help you better manage inventory. Overall, the Paris-based company making Manufacturing Planning Software leaves you in total control of and planning and production procedure.

Source - Axelor

Some notable features of the Open source production Scheduling software are as follows -

- Multiple Module integration (Marketing, Supply Chain, HR, and Financial Management)

- Reporting and Analytics Dashboard

- Visualized Reporting

- Production queue module to track the flow of goods and raw material

- Resource efficiency and utilization Calculator

- Historical calendar of production planning

- Smart System to group products by category sales forecasts, or even firm sale

- Easy formulation of purchase/production orders

- Order customization wizard (Works with multiple variances of BOM)

4. ErpNext

As the name suggests, the open source production Scheduling software is actually a part of the wider and more diverse ERPNext software. ERPNext’s production planning module consists of tools to maintain multiple job cards, production schedules, and inventory.

Used in and trusted by a variety of industry-related behemoths - such as Reliance, Zerodha, and Razorpay - the manufacturing planning system makes handling vendors and inventory especially easy. The software is cloud-based and the company also offers unlimited customer support.

Source - ERPNext

Some features of the open source production scheduling software are as follows -

- Multi-lingual support

- Automatic Stock Replenishment and balance checks

- Customized measurement metrics

- Capacity and Resource planning

- Inventory grouping management (Batched, Variants, serialized)

- Reporting and Analytics interface

- Subcontracting dashboard and tracking

- Multi-tool integration (Third-party and in-house)

- Mobile and tablet device scalability

- Accurate BOM tracking dashboard

- Shop Floor Management

5. Odoo

Used by over five million customers, this free and open source production scheduling software was formulated as a production scheduling tool to help companies manage production without the necessity of costly integrations.

Competing on aspects such as Planning, BOM management, maintenance, supply chain, shop floor control, and warehouse management, etc., Online Production Scheduling Software has four important integrations - Purchasing, PLM, Quality Management, and Maintenance.

Trusted and used by companies such as Toyota and Sodexo, the software is easy to configure, learn, and use.

Source - Odoo

Some important features of the free and open source production planning software are as follows -

- Dashboard for reporting and analytics

- Visualized data representation

- Shop Floor Automation

- Use of Bar Code to speed of manufacturing

- Grouping of orders into Work, Manufacturing and Repair Orders

- Managing bill of materials

- Planning and organizing work orders

- Optional routing

- Document Management

- Quality control aspects and tools

- Preventive and Corrective maintenance of goods

- Calendar control

- Notification management

- Worksheet control and recording

- Salesman Kit audits

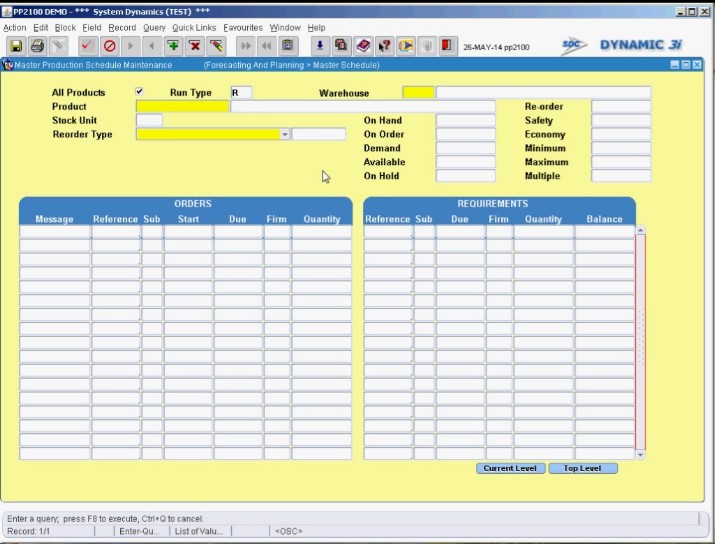

6. DYNAMIC 3i

This free production scheduling software helps users simulate a master schedule first which can then be optimized into a real schedule. The manufacturing scheduling system has two segments viz. Rough-cut capacity planning as well as Linkages.

Both these sections provide much-needed information on Resource Planning and Scheduling.

The Production Scheduling software has been created by System Dynamics Corporation - programmed entirely in Oracle - which has been producing ERP software for over three and a half decades. Dynamic 3i integrates multiple aspects of ERP and consists of over 36 modules after development.

Source - Dynamic 3i

The free production scheduling software has the following features -

- Production forecasting

- Master Schedule simulator to iron out deficiencies before implementing the real model

- Automatic Updates

- Comparison reports between sales and forecasting for better inventory management

- Grouping by product types

- Sales Analysis and order processing toolkit

- Automatic Scheduling

- Monthly to weekly balancing techniques

- Easy updates to the Master Schedule is possible

7. MRPeasy

This free production scheduling software specifically focuses on soothing the manufacturing and planning requirements of small manufacturers. Their motto is to produce Production Scheduling Systems that are not expensive and are easy to use. MRPeasy’s Online Production Scheduling Software makes use of real-time communication systems between departments to facilitate different techniques of scheduling. It also enables effective CRM handling to ensure customers are satisfied with order fulfillment.

The free production scheduling software is in use in over 300 industries ranging from 3D printing to Packaging. The easy to use interface and cloud integration are particularly useful for large order trackers. The production scheduling tool offers a free trial period after which the user has to purchase a paid version.

Source - MRPeasy

Some features of the free production software are as follows -

- Dynamic Rescheduling

- Bills of Materials (BOM) checker and tracker

- Shop Floor Kiosk Reporting

- Materials Reporting

- Data Analytics Dashboard

- Pre-order estimation of cost and lead times

- Workstation capacity management

- Document management

- Notification management system

- Inventory management and alert system

- Subcontractor management

- Routing and Production Calendar

8. Katana MRP

Katana is a free production scheduling software that is funded by the European Union. The reason behind the software’s founding and implementation was to ease the reliance on spreadsheets for large orders. Also, keeping in mind the expenses incurred in running large ERP systems as well as poorly designed interfaces, the creators of Katana envisioned a market gap and addressed it.

The software is cloud-based and works with Small and Medium enterprises. With advanced smart manufacturing features, it distinguishes itself by helping a variety of industrial businesses - ranging from Apparel and Footwear to Gin Crafting. Katana MRP consists of costing, sales, and procurement tools to aid businesses to make quick decisions on production decisions.

Source - Katana MRP

Some feature of the free production scheduling software are as follows -

- Production Planning - Raw material tracking; drag, and drop interface, Real-time shop floor updates

- Inventory Optimization - Distributed inventory management; automated transactions; inventory control of raw materials; Reorder point tracking.

- Sales order fulfillment - Reprioritization of tasks; Bottleneck Tracking; Availability tracker (Raw Materials, finished goods)

- Manufacturing floor control

- Purchasing - Order analysis; On-Time purchasing

- Costing - Product margin calculation-based pricing; Product recipe cost analysis

- Multi-tool integration

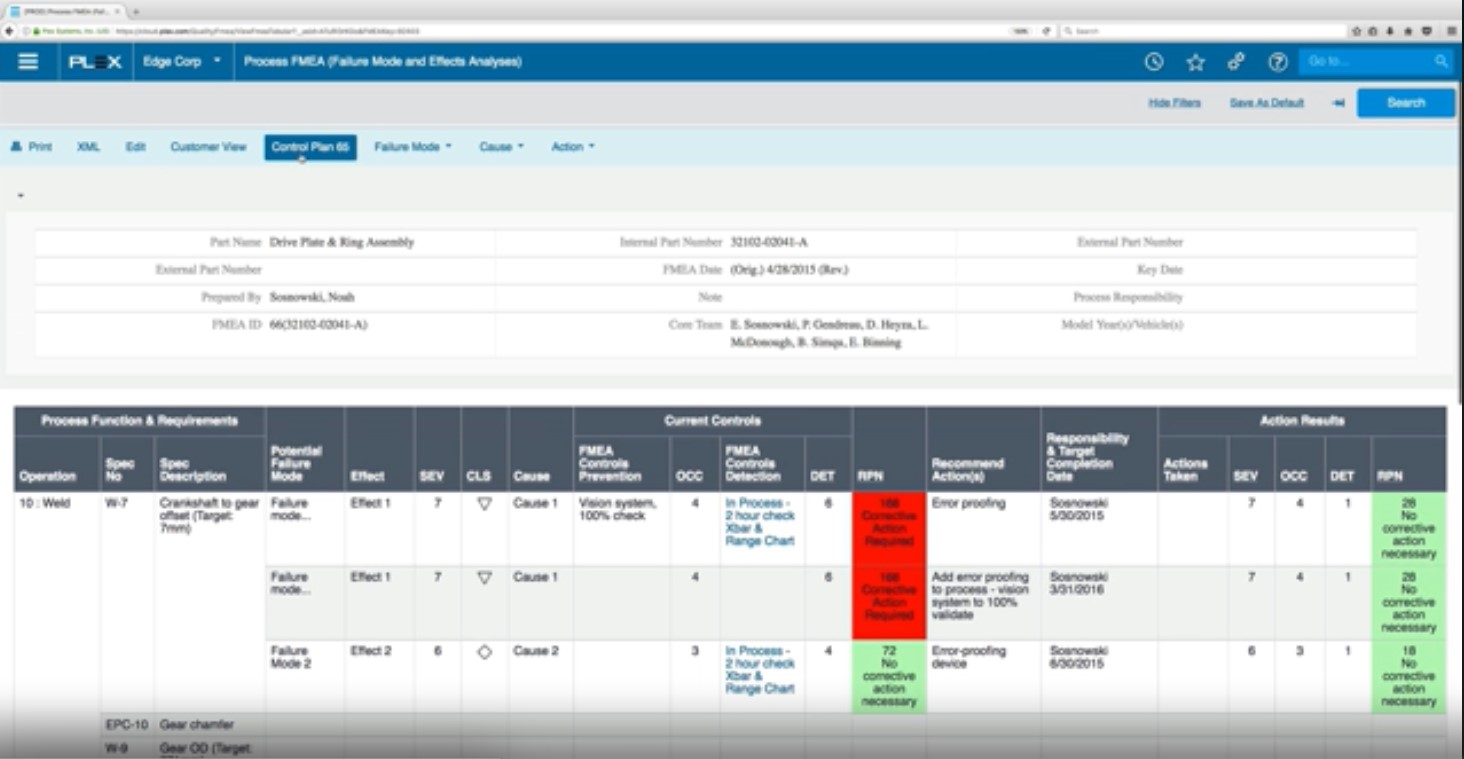

Besides the above, there exist a number of free and open source production scheduling software such as PlanetTogether, Futurmaster, Delfoi that are popular choices for users. Plex is one such popular production planning system that we will look at in detail below.

Plex is a popular production scheduling software that focuses on lean production management philosophies, the finite capacity scheduling technique, material requirement planning to build the perfect production planning software.

The production scheduling system uses a mixture of Kanban cards as well as Advanced Planning and Scheduling systems to deliver optimum value to a consumer who has ordered production goods from the firm.

The entire system has been exclusively built to run only on the cloud. Furthermore, Plex assures customers that they will no longer have to wait for big updates from ERP software vendors - Plex assurance daily code updates which are easy to deploy to keep the system up-to-date.

The software’s utility has been backed by the Manufacturing Enterprise Solutions Association (MESA), while it is trusted by over 650 customers worldwide.

Source - PLEX

Some features of the Production Scheduling System are as follows -

- Production Finite Scheduling

- Closed-Loop Quality Management - Error Proof Quality assurance, Issue Management

- Inventory Management

- Production Management

- Kanban Pull Scheduling

- Finite Capacity Constraints Management

- Workforce Capacity Planning

- Integrated Barcode scanning

- Product Lot management

- Analytics Dashboard

Conclusion

Production scheduling is a complex process that requires time, skill, and knowledgeability to implement. Organizations with effective production scheduling software have a significant advantage in this respect.

The use of supply chain analytics, data integration, and forecasting will pave the way for smarter, more effective production Manufacturing Planning Software.

Please use the comments section at the bottom of the page to give us your thoughts and review of the article.

Any feedback on the Production Scheduling Software featured on Goodfirms is appreciated. A list of Free and Open Source Production Scheduling software, open source production scheduling software, Free and open source production planning, as well as Free production scheduling software, are all available online on Goodfirms.

Synchro Pro, Preactor APS, Planvisage, are some notable software which users may also consider, with similar functionalities to those in the list above.

If you feel the need to consider other software types - spread out over various categories - have a glance through Goodfirms' Software Directory! Your ideal software solution awaits.