Ishan Mishra, Co-Founder and CEO at IshanTech

Posted on Nov 12, 2018

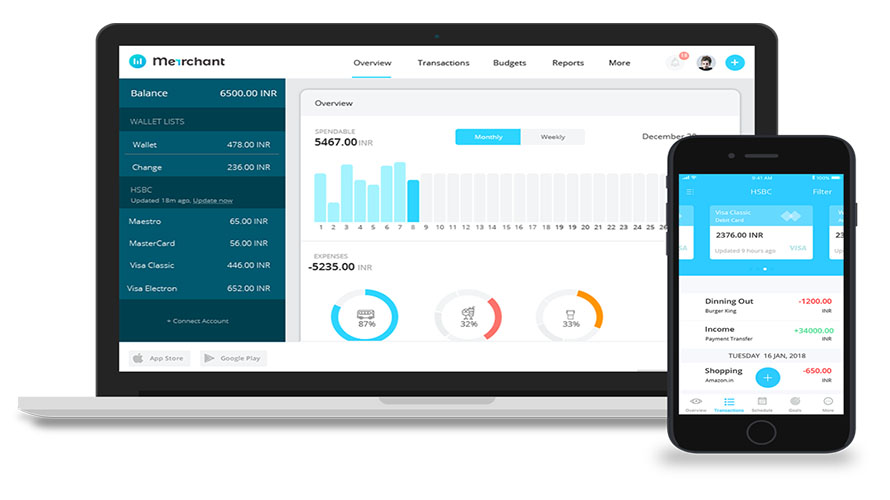

Start your Financial journey, let Merrchant guide you

Do you own or represent this business? Enter your business email to claim your Goodfirms profile.