Predictive Reliability & Risk Analytics

Predictive reliability & risk analytics for asset-intensive industries

Predictive Reliability & Risk Analytics is a data-driven analytics and engineering consultancy focused on improving asset reliability, operational safety, and risk visibility for asset-intensive industries.

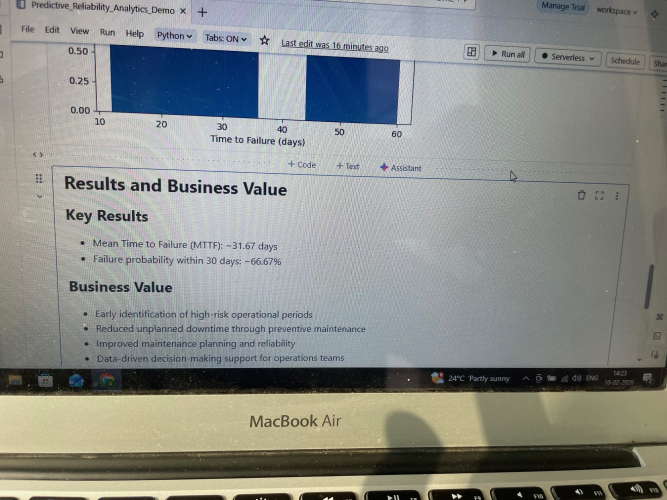

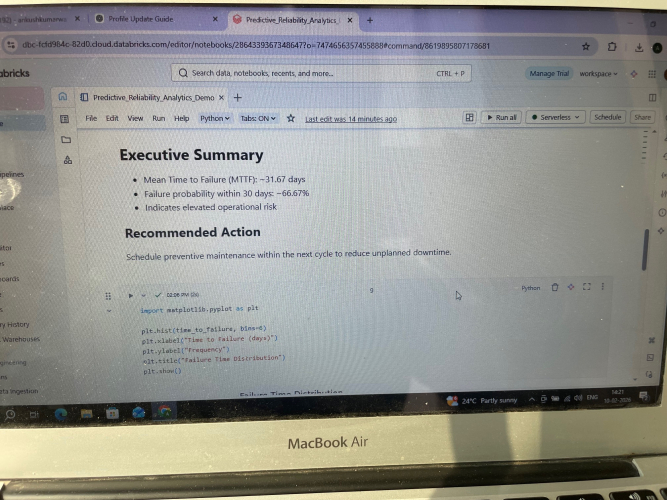

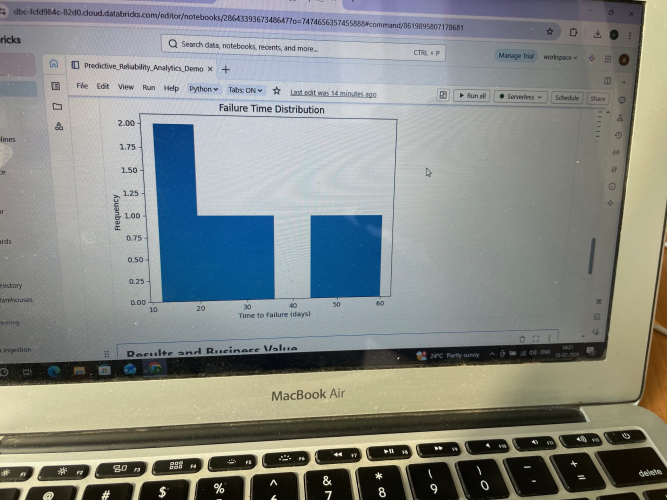

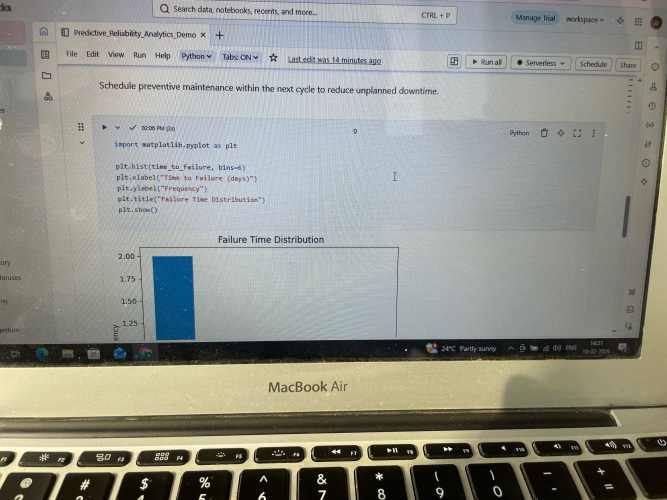

We specialize in predictive reliability modeling, risk analytics, failure analysis, and decision-support systems that help organizations reduce downtime, optimize maintenance strategies, and improve long-term asset performance.

Our solutions combine reliability engineering principles with statistical modeling, analytics, and simulation techniques to deliver actionable insights across the asset lifecycle. We work with manufacturing, energy, infrastructure, and industrial organizations to support maintenance optimization, reliability growth, and risk-informed decision making.

Founded in 2025, we aim to bridge the gap between theoretical reliability engineering and real-world industrial applications by providing practical, scalable, and cost-effective analytics solutions.

India

India

Detailed Reviews of Predictive Reliability & Risk Analytics

Client Portfolio of Predictive Reliability & Risk Analytics

Project Industry

- Oil & Energy - 50.0%

- Manufacturing - 50.0%

Major Industry Focus

Project Cost

- $0 to $10000 - 100.0%

Common Project Cost

Project Timeline

- 1 to 25 Weeks - 100.0%

Project Timeline

Clients: 1

- Confidential industrial analytics projects

Portfolios: 2