Table of Contents:

- What is a stock keeping unit?

- Who uses SKUs?

- What is the purpose of the stock keeping unit (SKU)?

- What are the SKU numbers?

- What is the importance of stock keeping units in business?

- SKU Management(Manual SKU Management and Automated SKU Management)

- Stock Keeping Units(SKU)vs.Universal Product Code: What's the difference?

- Best Practices for SKUs

- What is the role of the stock keeping unit in retail, supply chain, and warehouse?

- Stock Keeping Units(SKU) and Inventory Management

- Conclusive statement

- Key Takeaways

Ecommerce businesses these days demand a proper understanding of all the aspects of inventory management. In any business, order fulfillment can happen flawlessly if the strategy of order fulfillment is executed well. One of the most crucial elements to get acquainted with is the Stock Keeping Unit.

In this article, the reader will get to know everything from the basic concepts to in-depth information that helps in gaining the minute details of the stock-keeping unit.

What is the Stock Keeping Unit?

The stock keeping unit, also known as SKU, is a number given to a product for carrying out inventory management operations and tracking purposes. In simple words, a stock keeping unit serves as a unique identifier allocated to each product, which in turn helps quickly identify the product.SKUs are not barcodes.

The stock keeping unit classifies all attributes associated with the product that includes the details of the manufacturer's brand, description, material, size, color, packaging, and warranty terms.

For example- black velvet Ugg boots in the Bailey Bow style, size 8, may read "UGG-BB-BLA-08."

Who uses SKUs?

The SKUs are used in :

- Warehouses

- Retail stores

- Catalogs

- Etailers

- Product fulfillment centers

- e-commerce vendors

- Service Providers

- Etaliers

What is the purpose of the stock-keeping unit(SKU)?

The stock keeping unit is a scannable unique identifier or code printed on product labels in a retail store. The vendors can automatically track the movement of inventory with the help of a label.

SKUs can also be applied to insubstantial but billable products that may involve units of repair time in an auto body shop or warranties.

SKUs are used to track inventory levels. Managers can quickly determine which products are to be restocked with scannable SKUs and a POS (Point of Sale) system.

When a customer buys an item at the point-of-sale, then at that time, the SKU is scanned, and automatically the POS system removes the item from the inventory and records the data of the sale price.

What are SKU Numbers?

The Stock-Keeping unit numbers are a string of numbers and letters that signifies each product that is offered. The codes help in identifying the products present in the retailer shops or e-commerce shops.

The product's most essential characteristics, such as price, style, brand, color, type, and size, are all included in SKU numbers.

For each product, the SKU is unique, and in some cases, it may differ slightly with minor variations. For example- in an online shoe store, there can be one pair of shoe styles in three colors- black, brown, and white. The SKU number of this shoe style will be read as:

Black shoes, style no.1- S01-B

Brown shoes, style no.1- S01-B

White shoes, style no.1-S01-W

What is the importance of Stock Keeping Units in business?

The enterprises or store owners can efficiently manage and plan their inventory in many ways with the help of a stock-keeping unit system. Let's discuss the importance of SKUs in business:

- Everyone gets on the same page- The SKU system brings every user on the same page as a result allows them to understand the products and their movements efficiently.

- Multi-channel selling- Multichannel selling helps to reach a broader range of customers, increasing sales, and protecting the brands. The third-party marketplaces like Amazon and eBay use SKU to handle inventory for processing multi-channel sales.

- Reduce human errors- The inventory and other related data like pricing and stock account are appropriately managed by tracking products with SKU numbers. The errors related to mispicks and misships are all prevented with the help of SKUs.

- Easy and simple stock-taking- The stock keeping units help with smooth inventory management. The SKU lets users identify variants, which in turn helps in checking whether the inventory matches the actual stock levels.

- Enhanced customer shopping experience- The SKU codes enable customers to search for an item in the POS stock status quickly. When customers check out, the sales are noted, counting the SKU with the correct pricing, and as a result, the quantity gets automatically synced.

- Optimize inventory – The SKUs allow setting the reorder points on each product variant that helps keep inventory (list) at the maximum efficiency.

- Accurately manages warehouse operations- SKUs is helpful at various stages of inventory like a stocking, picking, packing, and shipping. With SKU barcode scanning, the item search and tracking become effortless and accurate.

- Prioritizes products- The stock keeping unit system helps in identifying sales volumes for each product variant. Maybe certain types of colors or size combinations are comparatively more popular.

- Forecasts the inventory- The SKU numbers organizes the Stock and tracks overstock, low stocks, or no-stock situations with the help of stock reports that are based on SKU codes. The flow of products can be monitored with the help of SKUs, and the forecast can be made of the inventory accordingly.

- Identify shrinkage in inventory - SKU helps in understanding the shrinkage in inventory. It determines which type of products are moving quickly. SKU is helpful for future planning.

SKU management(Manual SKU Management and Automated SKU Management)

It is essential for you to manage the SKU efficiently so that every piece of inventory can effortlessly meet the business's financial objectives. You can optimize your inventory levels and increase revenue by managing SKUs properly. In two different ways, you can manage SKUs-

- Manual SKU Management

- Automated SKU Management

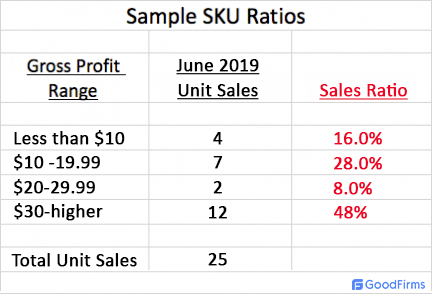

Manual SKU Management- In the manual SKU management process, two metrics are calculated; one is the SKU ratio, and the other is the sales ratio.

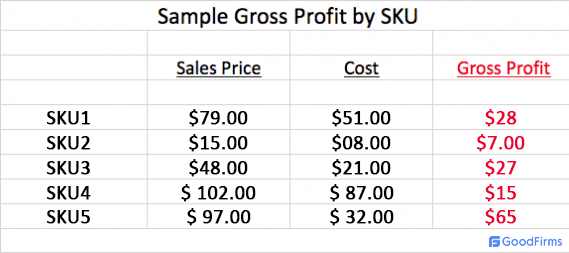

Calculate SKU ratio- In a spreadsheet, you can make a list of all your SKUs. In that list, you can note the price, cost for you, and the gross profit of each SKU. Determine the gross profit by subtracting the cost from the price.

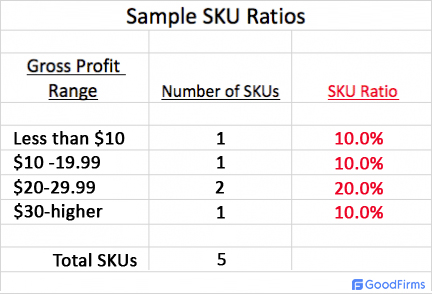

Now create gross profit ranges in the spreadsheet-like less than $10, $10-19.99, $20-29.99, and $ 30 higher. Note how many SKUs fall in each range. Then divide the number of SKUs by the number of total SKUs and multiply by 100. In this way, you can get the SKU ratio for each range.

Calculate Sales Ratio

Make use of the same gross profit rangesand note the number of units sold in a given time. Now divide the number of sales units in a gross profit range by the total number of sales units and then multiply it by 100 percent.

Automated SKU Management

By automating theSKU analysis, you can reduce the costs and improve the accuracy of the data. The SKU process can be automated by leveraging the Point-of-sale systems, which should be integrated with inventory management and other types of tools like barcoding.

You can electronically track items in real time by using software that helps manage the inventory. By employing an automated system, you can automatically update the inventor. Moreover, you can create a more proficient purchasing process and more useful sales and marketing strategies with the help of built-in analytics.

Stock keeping units (SKU) vs. Universal Product Code (UPC): What's the difference?

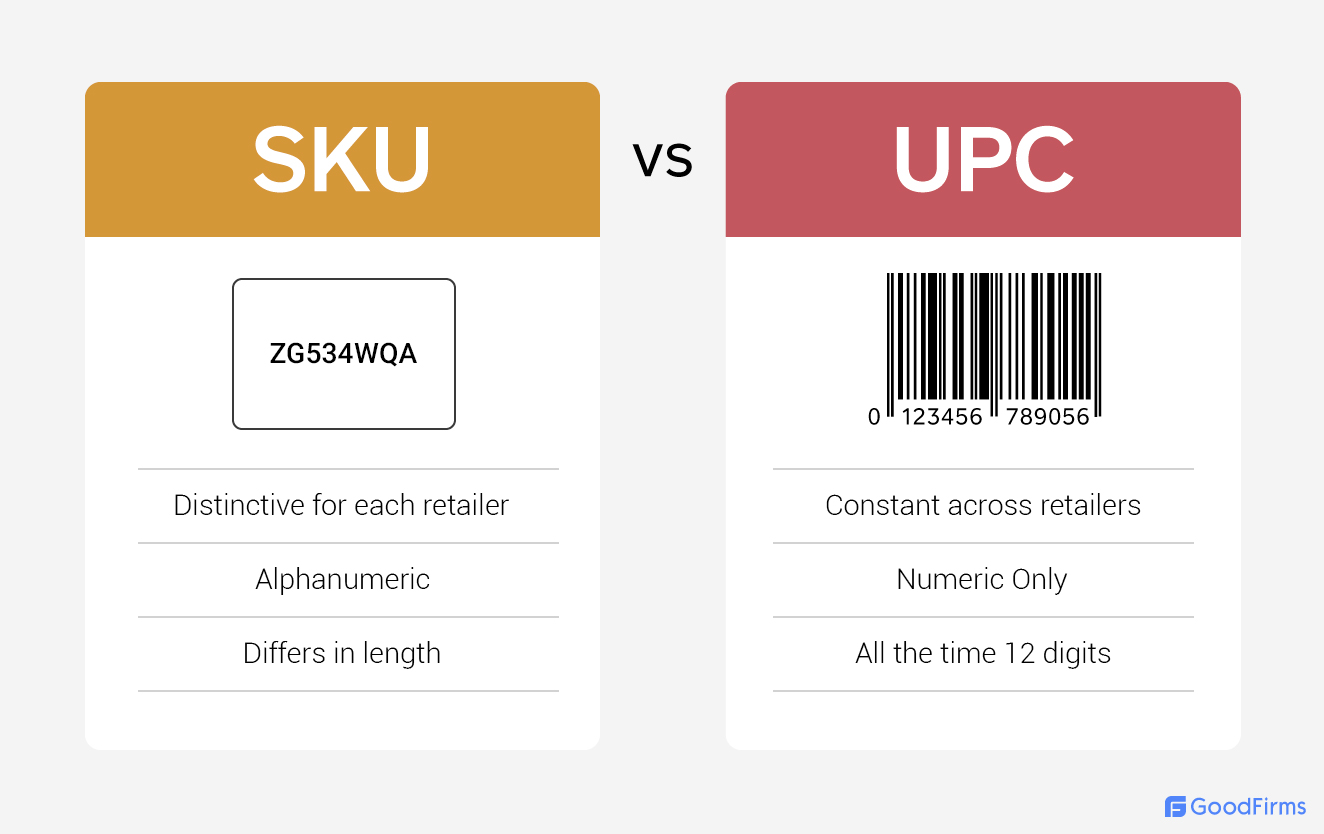

The SKU and UPC codes are used interchangeably by the people, but these two entities serve two different purposes for retailers.

- SKU is a non-standard numeric or alphanumeric code that generally lies between 6 to 9 characters long, whereas UPC is a 12-number code given to the manufacturer.

- SKU can be used for tangible (a physical product that can be perceived by touches like cars, books, milk, or gases) or intangible products (perceived indirectly like e-books, insurance, or downloadable software) while UPC is typically printed on tangible products as a barcode.

- SKUs give more particular information about the product. On the contrary, UPCs have more general information.

- Seller and his team can easily read and interpret the SKU, while humans can not interpret the UPC.

- SKUs are meant for internal inventory tracking purposes, along with operations. On the other hand, UPC codes are assigned externally and used to identify the product information and manufacturer. It is not meant for inventory by retailers and distributors at the point of sale.

- Based on the coding convention, the seller assigns code to a product of the stock-keeping unit while the Universal Product Code is assigned by GS1 US (Global Standard 1).

Best Practices for SKUs

You can go by the below-mentioned tips to make the SKU process easy, simple, and effortless:

- Short and unique – Try to make SKUs of not more than 30 characters. Avoid long SKUs as they are difficult to read and may not work with inventory management systems. Make sure you create a unique SKU for each inventory item you want to sell. Ensure you never reuse an SKU for an item that you don't want to sell anymore.

- No spaces or special characters - Simple characters will not create confusion with software systems. Avoid using spaces, quotes, commas, slashes (/or\),? &, or any other special characters. Make sure you use only dashes or periods as separators.

- Don't start SKU with a zero- Ensure that you don't begin SKU with a "0" as excel and other spreadsheet software can strip out the zero and can create confusion.

- Avoid just using the product title, and letters often confused with numbers- Make sure you leave the long descriptions for the product tile and not the SKU. The letters such as O, I, and L should be avoided to prevent confusion.

What is the role of the Stock keeping unit in retail, supply chain, and warehouse?

Role of Stock Keeping Units in Retail

The stock keeping units are used by retailers to track their inventory and sales, which in turn helps provide analytical data that helps develop relationships with the vendors and customers.

The SKU numbers are valuable for retail store owners as they provide the following benefits:

- The SKU system improves customer experience by making the tasks related to customer service or check out move much quicker with fewer errors.

- The SKUs provide an improved shopping experience by optimizing the store's layout so that the customers and staff can quickly and easily find the items.

- The SKUs provide retail stores a manageable way to track the entire inventory down to the last item. The SKU system can quickly recount the number of items present in the Stock.

- SKUs make selling to other stores easier, which, in turn, helps grow the brand and make more money.

The retailers can easily advertise stores with SKU numbers. The retailers can win the business by doing a practice of "price-matching" with the competitors. With a unique SKU number for identical items, the retailers can protect margins easily.

Role of Stock Keeping Units in Warehouse

The SKUs keep track and manage stock in a warehouse. The stock keeping unit serves as a product's reference number, which is registered in a company's system. In the warehouse, the SKUs help in recognizing a specific product. The SKUs track inventory to know how many particular products are available in the warehouse. It enables to reconcile stock levels of products.

The SKUs identify shrinkage in inventory. Through analysis, the SKUs can determine which products are most profitable. The reorder points of products are also identified with the help of SKUs. The customers can quickly find products and can save their valuable time with the help of SKUs.

Role of Stock keeping Units in Supply Chains

The SKU numbers improve supply chain visibility and help in giving granular insights into the shipment process. It becomes easy to achieve the inventory turn and pre-planning capabilities that the supply chain needs to flourish by developing visibility across the supply chain.

The SKUs help in tracking shipments from end-to-end. If the shipment details are accessed at the SKU level, then there can be better inventory control. It is easy to know the location of the products with the help of SKU numbers. With SKU numbers, you can:

- Know exactly where your products are

- Track shipment locations

- Track U.S. customs statuses and delivery

- Uncover product information like cost, duties, freight, and number of units in transit

The SKU numbers enable the review of SKU unit Cost, which in turn helps in calculating landed costs accurately and planning the product prices.

SKU can inform future shipments. It can uncover trends in shipment deliveries, inventory progress, and freight spends. The collected data can help determine inventory levels along with product prices, predict future performance, and make informed changes.

Stock Keeping Units (SKU) and Inventory Management

The stock keeping units are used in the inventory management system to store and track products efficiently. The multi-channel sellers and brand owners use an inventory management system to simplify the process of order fulfillment. Let's know how SKU plays an essential role in the inventory management process:

- SKUs allow tracking the inventory right down to individual variants of every product (color, size, etc.). They are a crucial part of a sound inventory management system. They are unique and specific to a particular location. For example, if there are two warehouses stocked with identical products, they will have different SKUs for an efficient inventory management process.

- SKUs identify the product with the most minute details and represent the most fine-grained level. They are considered central to optimizing the inventory, which is a part of the inventory management technique.

- Implementing the SKU best practices (like making the SKUs easy to understand, arranging the words according to importance, and avoiding using letters that look like numbers, spaces, accents or symbols) can help in understanding the product codes quickly for your inventory.

- SKU management helps in reducing inventory shrinkage. It minimizes the opportunity for theft in the warehouse.

- The SKUs system helps in knowing when there is a need to reorder stock. Due to the proper arrangement of the product and its variant, the organization will never go out of Stock or end up bearing unnecessary carrying costs for excess Stock.

- The SKUs help determine the popularity of the products and individual variants, which in turn helps determine how to invest and discontinue them.

- SKU system reduces the carrying costs associated with overstocking slow-moving products. The sound SKU system is considered central to inventory optimization. You can make more informed decisions about purchase orders if you know more about your stock levels and product movements.

- The strategic business decisions can be made by labeling all the products with SKUs. It helps in providing you the critical data regarding the customer's requirement, where the cost can be cut, and where the efforts and budget should be focused.

Conclusive statement

The stock-keeping units (SKUs) are making the shopping experience more efficient than ever before. Stores, catalogs, e-commerce vendors, service providers, warehouses, and product fulfillment centers track inventory levels with the help of SKUs.

The SKU is a combination of numbers and letters that shows information related to the manufacturer, price, color, and size of the product. The company assigns the SKU to the products.

Retailers and other types of businesses can easily manage their business proceedings with the help of SKUs that enable them to know:

- How many products do they have in the Stock?

- When to reorder?

- Which products are or aren't selling?

SKUs save a lot of time and effort for companies by allowing them to easily track the stocks of their items. Due to continuous monitoring, the company can easily make out when to reorder the product. To understand the other essentials of Inventory management, you should go through the Inventory Management Buyer’s guide specially crafted by the experts at Goodfirms.

Hoping the information mentioned in this article has helped readers gain insights into the stock-keeping unit management process. If there is any other information required to be discussed, then feel free to contact Goodfirms.