Novacura

Extend the reach of your ERP with easy to build

Since 2005, our team of 200+ consultants and developers has built a strong reputation as a top ERP consulting company and trusted IFS partner in Europe and North America. We support manufacturing, logistics and service companies with modern ERP solutions that simplify complexity, streamline operations, and improve decision-making.

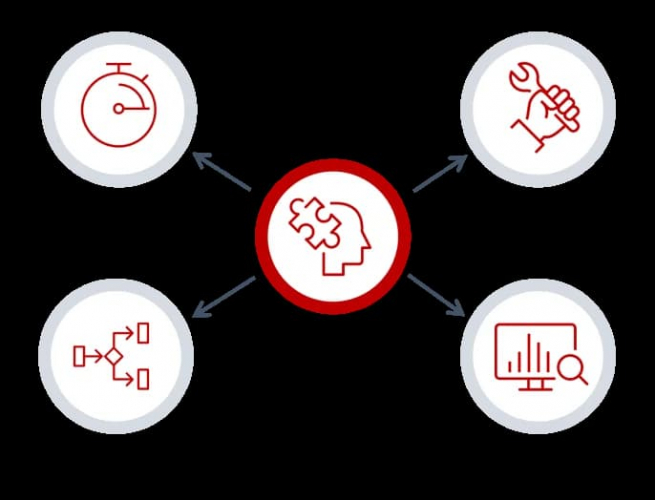

Our portfolio covers full-cycle ERP consulting capabilities, including:

-

End-to-end IFS services: IFS application services, IFS managed services, and ongoing IFS service partner support

-

Low code software development with Novacura Flow to accelerate business transformation

-

Tailored industry software solutions and ERP software modules for manufacturing, logistics, and service sectors.

Why clients choose us:

-

Recognized among the top ERP software companies and a reliable ERP partner for digital transformation.

-

Deep expertise in IFS and Infor M3.

-

Proven track record delivering measurable ROI with the best ERP solution software company practices.

As part of the IFS partner network, we combine technical excellence with industry expertise, ensuring every deployment delivers maximum customer value. Our mission is to be the ERP company that drives growth, innovation, and long-term success for businesses worldwide.

United States

United States

Detailed Reviews of Novacura

Client Portfolio of Novacura

Project Industry

- Transportation & Logistics - 20.0%

- Manufacturing - 40.0%

- Food & Beverages - 20.0%

- Industrial - 20.0%

Major Industry Focus

Project Cost

- Not Disclosed - 100.0%

Common Project Cost

Project Timeline

- Not Disclosed - 100.0%

Project Timeline

Portfolios: 5

.jpg)