Efficient management of the storage and handling of the products and materials in the inventory and the supply chain contributes to the overall enhancement of customer experiences, client-business objectives, efficiency, and cost reduction. As new technologies and trends like the use of big data, analytics, artificial intelligence (AI), autonomous vehicles, drones for last-mile delivery, robotic process automation (RPA), blockchain, warehouse management software, etc., are offering a high level of transformation in the warehouse processes, the distribution industry is heading towards a sustainable and efficient functioning.

If you are new to this industry and have been facing issues like Inaccurate inventory information, flaws in orders, labor issues, miss-management of data, poor quality control, non-familiar with the seasonal demand, anticipatory inventory, overages, shortages, damages, not adapting the latest technologies, and substandard picking process, etc., then this blog can be of utmost help for you.

This blog introduces you to the concept of the top 3 support components - AI, automation, and WMS software or warehouse management software pointing out its mission to optimize warehousing operations for better performance, efficiency, productivity, and sustainability. It also sheds light on how these 3 components can facilitate the strategized, timely flow of inventory from shipper to customer without any flaws.

Top 3 Support Components of Warehouse Management

Whether your warehouse requirement is for long-term or short-term storage, whether your product demands are increasing, decreasing or fluctuating, whether your staff possess little or no warehouse operating skills, whether you lack the ability to position low-volume inventory geographically, the crux is to reduce cost, improve customer service, and keep up with the business objectives. For this, Warehouse management today majorly relies on three components. They are;

- Automation

- Artificial Intelligence

- Warehouse Management Software

In a research conducted by Goodfirms on the usage of automation and artificial intelligence, 46.7% participants indicated that they use AI, and 22.1% indicated that they use automation.

In FY 2022, the warehousing industry saw a massive 62% increase in the volume. The increase in the number of online shoppers and product manufacturing is likely to drive this growth further in the upcoming years. As a result, it becomes very critical for warehouse managers to optimize warehousing operations using technologies like artificial intelligence, automation, and advanced warehouse management software.

Artificial Intelligence in Warehouse Management

The global artificial intelligence market size crossed $150.2 billion in 2023 and is anticipated to grow at a CAGR of 36.8% in the upcoming years. AI technology is transforming every industry today. Also, AI has already made its way to warehouse operations to achieve a new level of efficiency that was never expected. With data-driven insights, AI facilitates efficient warehouse management with real-time visibility, process optimization, enhanced logistics, improved customer service, predictive supplies, and many more. Undoubtedly, modern warehouses need to have a strategy for AI-based warehouse management.

“AI has entered the public consciousness: it’s cool and hip to place it front and center in a product, a sign that companies are ambitious and forward thinking.” - From: The Verge.

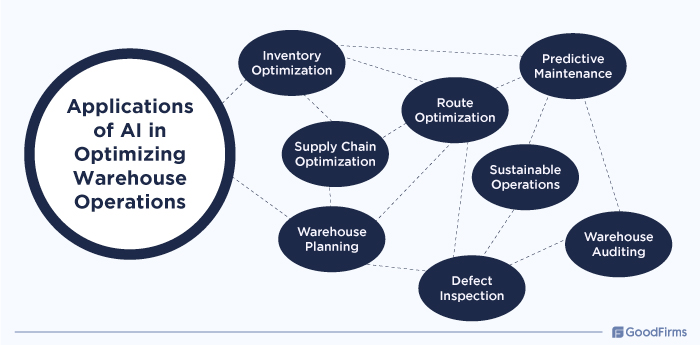

Applications of AI in Optimizing Warehouse Operations

Inventory Optimization

According to a survey conducted by a supply chain management company, around 78% of the supply chain executives indicated that they are leveraging artificial intelligence technology to optimize their inventory network, warehouse resource management, supply chain risk management, demand forecasting, manufacturing analytics, cost optimization, and much more. The predictive analytics features of AI tools can analyze both existing and historical data to optimize the inventory, reduce extra stocks, and prevent stockouts for better operational performance. Some AI warehouse management software like Logiwa and Focus WMS offer advanced inventory management functionalities to optimize warehouse operations at both macro and micro level. Predictive forecasting, and demand forecasting are two major benefits of AI in inventory management, that eventually impacts warehouse management. The role of AI here is to gather and group information. H&M, Zara, Fast Fashion are already using Artificial Intelligence to optimize their supply chain. Business giants like Walmart, ASOS, and Walgreens are already implementing AI to optimize their warehouse and avoid stockouts or overstock situations.

Supply Chain Optimization

32% respondents of a Deloitte study believe that AI can improve supply chain resiliency. Not only resiliency but there’s a chance that it will offer end-to-end visibility in the entire supply chain in the upcoming times, besides providing capabilities like shipment monitoring, transportation management, determining optimal sourcing methods, matching supply with demand, etc., bringing better accuracy and efficiency in the supply chain while ensuring continuous optimization.

Warehouse Planning

Any warehousing business, irrespective of size and type, aims to effectively plan the warehouse operations and functions in order to achieve improved results. Artificial intelligence significantly benefits the warehouses owing to capabilities such as layout optimization, characteristics-based automatic storage assignments and cross-docking optimization. In addition, AI can analyze the current warehouse space that is in use to ensure optimized storage density and determine potential areas of improvement. Many companies like Prologis use an AI-powered TestFit tool to assess the feasibility and viability of warehousing sites.

Route Optimization

In a survey conducted by Goodfirms, around 61.8% organizations indicated that they experience financial loss due to late deliveries. AI can assist in reducing such loss by optimizing the routes. Advanced AI warehouse systems can analyze real-time data to let drivers know about the most efficient routes, combine similar orders, make data-driven decisions, track efficiency metrics, evenly distribute the tasks among workers, etc., ensuring optimal utilization of resources and reduced errors. Apart from these, AI also helps warehouses plan dynamic routes, explore alternative delivery options, balance loads across different vehicles, etc., for better order fulfillment.

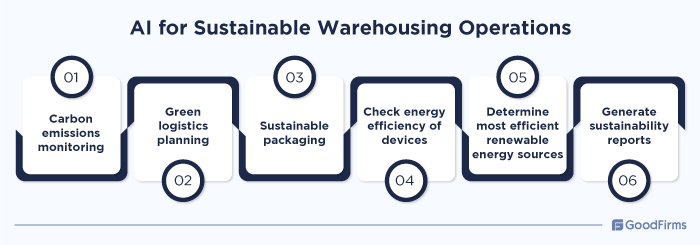

Sustainable Operations

As per an IBM report, 46% business executives believe that AI can enhance their sustainability performance. This is beneficial in attracting around 30% global customers who stopped purchasing products from their favorite brands owing to improper sustainability practices. AI helps warehouse managers in monitoring carbon emissions from warehouse operations, planning green logistics, sustainable packaging, checking energy efficiency of devices, determining most suitable renewable energy sources, etc. Not only these, AI also helps warehouse managers in generating sustainability reports for energy consumption, carbon emissions, industrial waste, etc., to efficiently achieve net zero goals.

Defect Inspection

Artificial intelligence tools with advanced models and algorithms are also used to automate and improve defect inspection operations in warehouses. With AI defect inspection technology, warehouses can effectively implement quality control measures, automate visual inspection, recognize defect patterns, reject defective products, analyze quality issues from suppliers, etc. For instance, Amazon is using a sophisticated AI damage detection technology to prevent the shipment of damaged products to customers from its warehouses.

Warehouse Auditing

The natural language processing capabilities of AI tools can extract meaningful insights from raw financial reports, emails, contracts, sensor data, etc. Not only extracting, but such sophisticated capabilities can also understand these insights through which managers can easily identify potential errors. Moreover, such audit systems also offer functionalities to record admin activity, access audit data logs, check order accuracy, automate audits, compliance audits and many more, eliminating the monotonous tasks for warehouse auditors.

Predictive Maintenance

The predictive maintenance market crossed $9.15 billion in 2023 and is anticipated to grow with a CAGR of 24.2% in the upcoming years. One of the major drivers behind this growth is AI which will also improve the accuracy of the predictions. It greatly benefits warehouse managers in continuously monitoring the equipment, predicting machine failure, reducing downtime, extending the machine lifespan, etc. Skoda is a live example of using AI-powered predictive maintenance to detect anomalies in assembly line equipment.

When it comes to AI in warehouse management, it is remarkable what this technology can do to surpass business expectations. It can optimize inventory, supply, and delivery management and improve the overall customer experience for better operational excellence.

Automation in Warehouse Management

“The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency.” – Bill Gates, Former CEO, Microsoft

Mechanizing mundane and repetitive tasks that require minimal human involvement is automation. In Warehouse, automation applies to both digital and physical automation involving the movement of goods and is directly related to inventory, supply chain and delivery management. The global industrial automation market was valued at $192.5 billion in 2023 and is anticipated to retain a CAGR of 10.30% in the upcoming years, owing to the increasing use in warehousing and other related sectors. Warehouse automation systems are highly beneficial in increasing workplace safety while handling big machines, improving operational efficiency and offering better service. Apart from these, automation in warehouses also hugely contributes to error reduction, performance improvements, optimal utilization of available space, better control over inventory, lower operating costs, etc. In a research conducted by Goodfirms, around 46.3% organizations, including warehouses, plan to implement more automation in processes.

Applications of Automation in Optimizing Warehouse Operations

Automated Sorting Systems

Automated sorting systems are used in warehouse operations to identify, sort and divert products to their designated positions or stacks. These systems use conveyor belts, tilt-tray sorters, pusher sorters, RFID tags, etc., to precisely move goods to sorting points. Such systems, using a predefined criteria can optimize space utilization and product sorting in warehouses to reduce labor costs and improve throughput. FedEx Express is a leading US firm that uses such systems to optimize business processes and provide better services to customers.

Automated Goods-to-Person Systems

These automated systems are used in warehouses to move products to the pickup stations. These automated systems command fixed or autonomous mobile robots to bring the required products to the human associates. Such systems eliminate the need for human associates to unnecessarily move here and there which means better productivity.

Radio-Frequency IDentification (RFID)

RFID systems are actively being used to efficiently control and organize the warehouse inventory and its data. Unlike traditional barcode systems, RFID does not require a direct line of sight to scan the product. It allows warehouses to increase the volume and speed of order processing for better output.

Autonomous Robots

Autonomous robots are increasingly being used in warehouses to pick, stack and store products. In addition, they are also used for inventory management, order picking, moving products across warehouses, packaging, palletizing, surveillance, collaboration robots, etc. Owing to the benefits, nearly 95% organizations are planning to deploy more robots for smoothly performing their operations. Companies like Coca Cola have already invested in autonomous robots to automate processes like pre-delivery assembling, palletizing and new product wrapping.

Warehouse Automation

Completely automated warehouses are not a dream anymore; instead, they exist owing to the advancements in automation technologies. Automated warehouse systems use robotic arms, conveyor systems, forklifts, drones, etc. to easily move products across warehouses and ensure a smooth flow of products between different stages of the fulfillment process. For instance, DHL is using autonomous drones for efficient multi-story warehouse management, inventory management, logistics, etc., resulting in 20 times more efficiency. Similarly, Tesla also uses automated drones in its Berlin-based Gigafactory to accurately count pallets and manage inventory.

Automated Document Handling

Improper handling of documents often leads to data or financial loss, which can be reduced through automated document handling. Document management software when integrated with warehouse management tools along with automation capabilities can capture and digitize paper documents, exchange business documents, minimize manual data entry, eliminate errors, share information to other systems, etc., to facilitate faster document processing, and update other sections while maintaining accuracy.

Safety Management

Many warehouse automation systems offer predictive maintenance capabilities through which unwanted or fatal safety incidents can be eliminated from warehouse operations. These systems using advanced analytic and visualization techniques can cohesively analyze the data from different machines and sensors. Through this, machine operators can determine any potential breakdowns and can repair them on a timely basis if found. One great example is Amazon that uses automated robotic solutions like Sequoia and Digit to improve workplace safety and improve the order fulfillment process in its warehouses.

Apart from these, there are many more applications through which automation can and will be implemented across warehouse operations. According to a Goodfirms survey, 54.9% of organizations are looking to upgrade or increase automation technologies in warehouse operations to further increase revenue and profits.

Warehouse Management Software

The global warehouse management software market is anticipated to reach $8.9 billion in the upcoming years with a CAGR of 16.7%. Warehouse management systems offer several benefits such as quick integration with other systems, space optimization, better inventory visibility, smooth shipping and return process, simplified product tracking, efficient warehouse management, reduced operational costs and many more. Although WMS has been around for some years now, the current version of this software comes with advanced functionalities and interoperability to match with the new generation trends and requirements.

Applications of Warehouse Management Software in Optimizing Warehouse Operations

Warehouse Space Optimization

According to a research survey, 27% businesses are selling their excessive inventory in secondary markets to avoid high storage costs. Such businesses can use warehouse software to optimize the flow of products, space wastage and time to locate a product while efficiently utilizing the available space and ensuring reduced overhead costs. A properly built WMS can analyze the warehouse space and floor plan to optimally use the warehouse space. Tools like SAP WMS come with intelligent slotting rules and available space analysis to ensure effective space utilization.

Inventory Tracking

A warehouse management tool is responsible for tracking the inventory flows in the warehouse premises. It enables warehouse managers to effectively monitor the supply, demand, and inventory functions with real-time visibility into available stock, replenishments, purchase orders, storage, etc. Through this, they can procure the commodities whenever required at the right time, optimize the warehouse space and ensure evenly allocation of inventory. A recent survey by Goodfirms indicates that 30.7% store owners manage and track their inventory using inventory management tools. A WMS with inventory management capabilities can eliminate the extra costs of spending on separate inventory management tools, which will also assist in growing profits.

Order Management

Efficient order management is a critical function of any warehousing firm to enhance customer satisfaction. A WMS with robust order management capabilities can process customer orders, receive/create sales orders, sort, and print order lists, create/send invoices, manage shipping and returns, etc., providing a centralized system to warehouse managers to acquire accurate visibility in the order management process.

Financial Management

Warehouse management tools like Softeon WMS come with configurable billing management features to streamline financial activities. Many WMS also offer other features, such as customizable metrics, billing systems, financial reporting, multi-currency pricing, landed cost management, automated balance sheet, etc. Through such features, warehouse managers can calculate revenue, tax and cost of products while making informed and data-driven decisions. Such features allow warehouses to know their most profitable customers, best sales channels, top-performing products, etc. Many WMS also offer integration with QuickBooks and Xero to perform different accounting-related tasks from a single place.

Supply Chain Management

In a survey conducted by PWC,83% supply chain executives confirm that their existing systems for supply chain do not return anticipated results after implementation. A well-developed WMS can help warehouses achieve their desired supply chain results. Warehouse management software helps managers acquire real-time visibility and insights into the supply chain, manage risks and disruptions, predict market trends, identify supplier delays, determine sudden spikes in demand, improve distribution network processes, etc., to improve shipment speed and accuracy in the supply chain for better optimization.

Risk Management and Forecasting

Risk analysis and prevention are very crucial to the success of a business. A WMS with proper risk management and forecasting abilities can analyze operational data to provide valuable insights and create forecasts while considering the possible risks or disruptions. Not only this, such tools can also identify and prioritize the demand for seasonal products to manage costs, a priority for the 28% warehouse managers during peak seasons. Leading companies like Conforama and Rexel Spain are using Generix Group WMS to prevent various risks associated with production, storage, logistics, finance, etc.

Labor Management

Many WMS systems also offer features such as shift scheduling, payroll management, performance control, safety management, etc. Through such features, warehouse managers can track the time consumed by the workforce in performing their tasks. Some warehouse systems also offer other labor management related functions such as procurement schedule analysis, performance management and forecasting the number of employees needed to perform their activities on specific days and in specific zones. This is beneficial for warehouses in retaining employees, which is necessary to improve the fulfillment process, according to 32% supply chain professionals of a survey.

Besides these applications, advanced warehouse management software is also actively used for 3PL management, barcoding/RFID, category customization, multi-location, quality control, returns management, shipping management, stock management, etc., to efficiently manage various functions while ensuring optimal service delivery.

Conclusion

Until a few years back, Warehouse management was a task of utmost challenges as it involved manual entries, coordination with multiple divisions and departments, which resulted in errors, irreparable. But, currently, things are a bit different with the arrival of automation, artificial intelligence, and next-generation warehouse management software. The evolution of these technologies over time may completely eliminate challenges such as high operational costs, resistance to change, demand forecasting, inventory optimization and order fulfillment. In addition, new technologies like IoT, AR/VR, blockchain, etc., in combination with AI, automation and warehouse management software will foster better collaboration and communication between the warehouses, suppliers and consumers.

The time is not far when one can see fully automated warehouses with zero human interaction, which will also boost the order fulfillment process and customer experience. If you wish to learn more about the state-of-the-art, cloud-based, free and open source, and top warehouse management software, do visit Goodfirms.