Adott Solutions

Transforming ideas into market-ready products

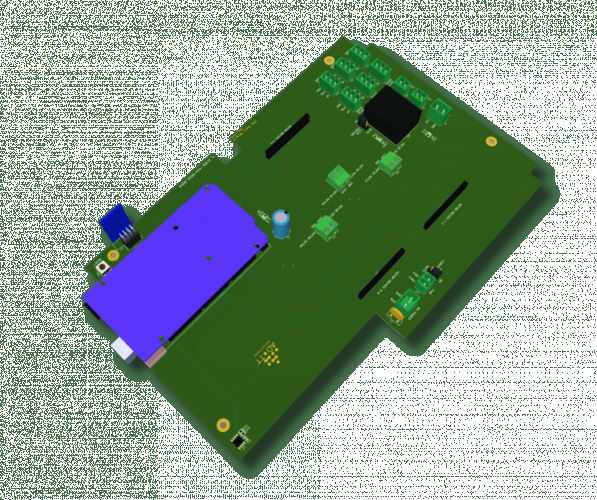

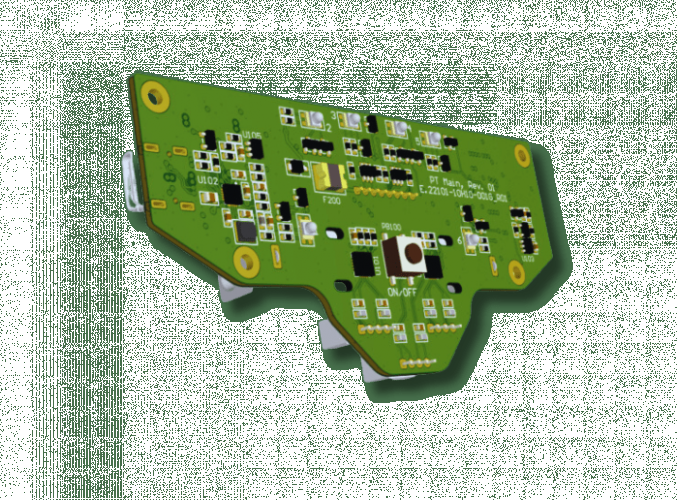

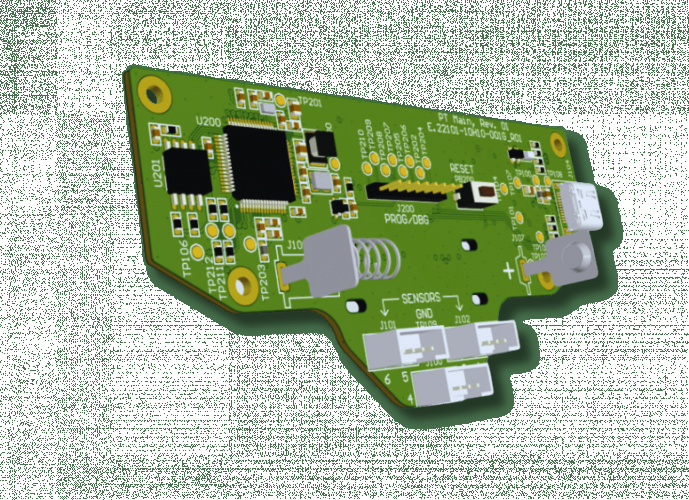

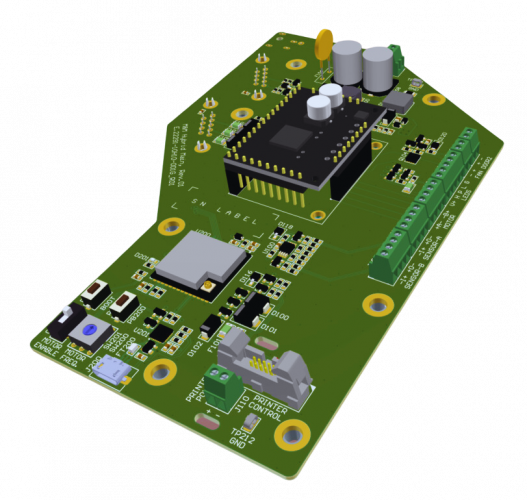

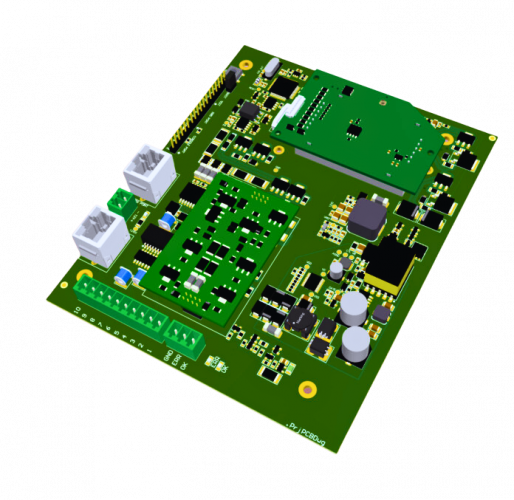

At ADOTT Solutions, we specialize in comprehensive engineering services that bring your ideas to life. From hardware and software design to product manufacturing and intrinsic safety certification management, we provide end-to-end solutions tailored to your unique needs. Our team of experienced engineers excels in delivering complex services and finding creative engineering solutions for diverse industries.

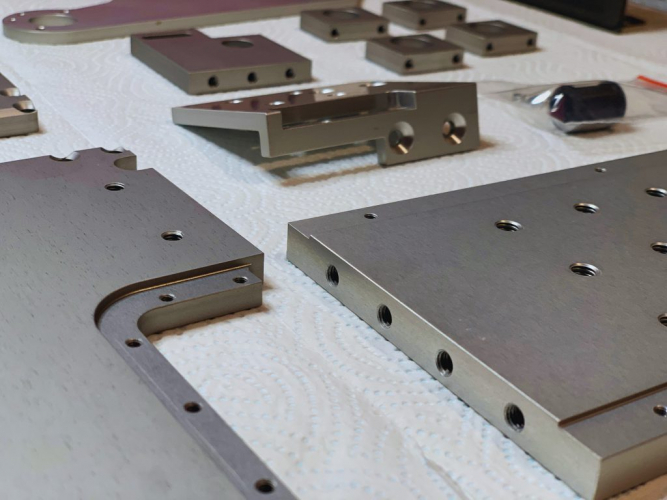

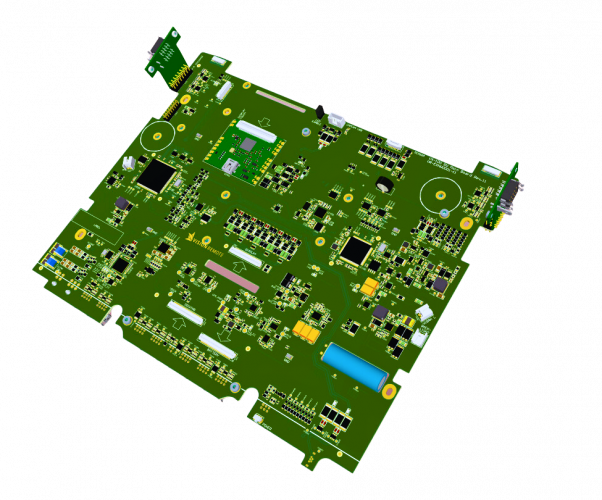

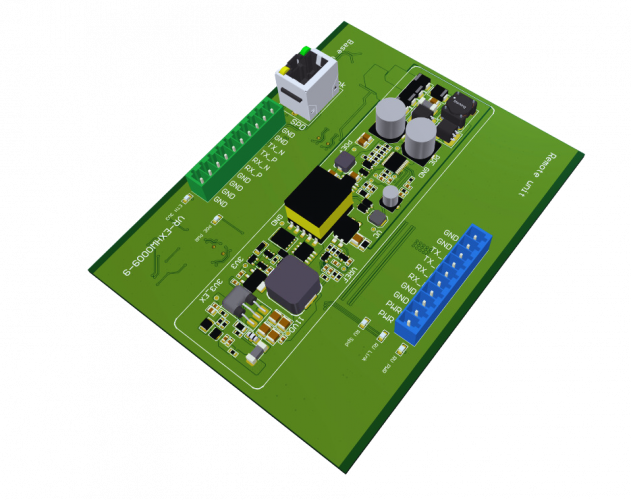

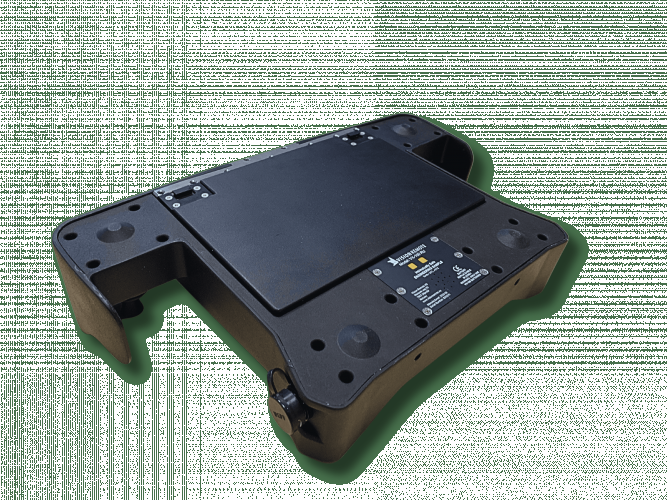

Engineering services - From concept to reality, our team of skilled engineers is dedicated to turning your visions into tangible, market-ready products.

Certification Management -Trust our expertise to guide you through the certification journey, allowing you to focus on your core business while we handle the intricate details.

Our expertise caters to various industries, including:

◦ Medical/Healthcare

◦ Chemical & Pharmaceutical

◦ Food Manufacturing

◦ Energy, Oil & Gas

◦ Automation

◦ and more

Hungary

Hungary

Service Focus

Industry Focus

- Oil & Energy - 40%

- Healthcare & Medical - 20%

- Manufacturing - 10%

- Other Industries - 10%

- Startups - 10%

- Automotive - 5%

- Telecommunication - 5%

Client Focus

Detailed Reviews of Adott Solutions

Client Portfolio of Adott Solutions

Project Industry

- Oil & Energy - 50.0%

- Healthcare & Medical - 33.3%

- Manufacturing - 16.7%

Major Industry Focus

Project Cost

- Not Disclosed - 100.0%

Common Project Cost

Project Timeline

- 1 to 25 Weeks - 16.7%

- 26 to 50 Weeks - 33.3%

- 51 to 100 Weeks - 50.0%

Project Timeline

Clients: 4

- Artee Flow Controls

- AD Medical

- PL3

- Vision Remote

Portfolios: 6