srushty Global Inc

Creations Engineered

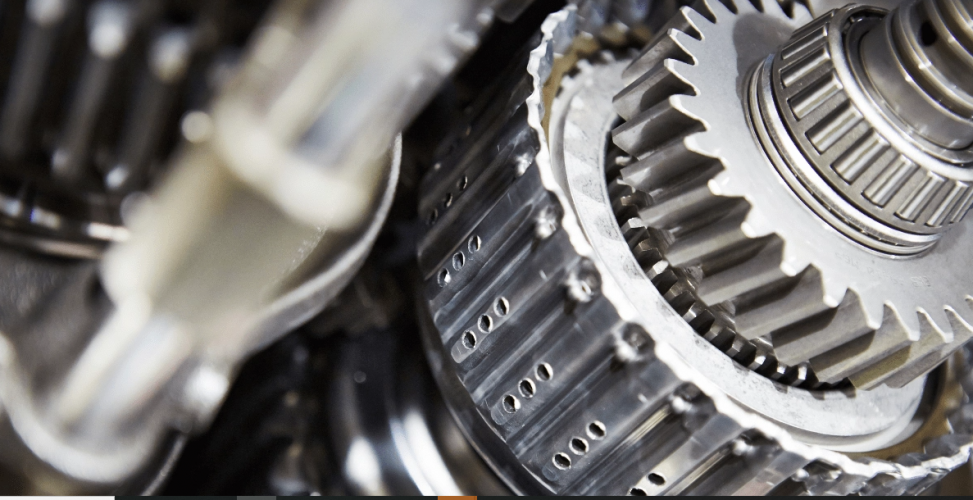

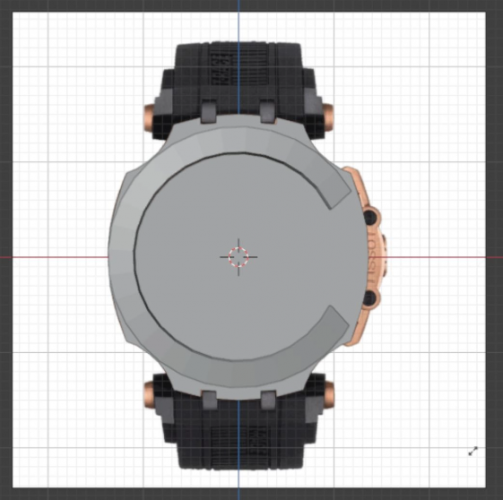

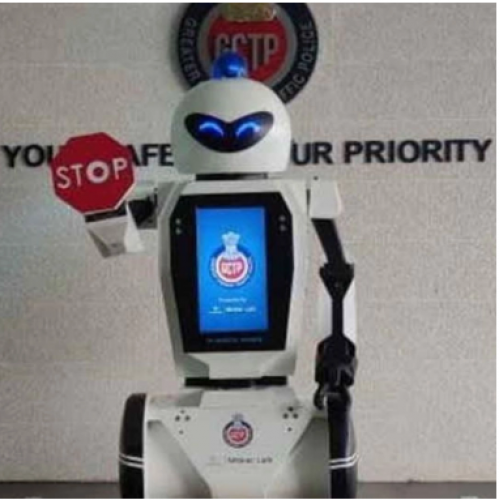

Srushty is a 14-year-old company with a vision of creating every idea into a marketable product with world-class engineering solutions. At Srushty, creation is in our DNA. Over the years Srushty has seen remarkable growth expanding services across the globe with a spectrum of offerings in hardware product development, engineering services, IoT software development, contract manufacturing and 3D modeling. We are on a mission to be the catalyst of creation by being the growth enablers for businesses.

India

India

2C&4C, 22-23, 2nd Street River View Residency Karapakkam,

Chennai,

Tamil Nadu

600097

+91 7010478046

NA

50 - 249

2010

Service Focus

Industry Focus

- Automotive - 10%

- Business Services - 10%

- Healthcare & Medical - 10%

- Manufacturing - 10%

- Utilities - 10%

- Retail - 10%

- E-commerce - 10%

- Startups - 10%

- Enterprise - 10%

- Industrial - 10%

Client Focus

50% Small Business

25% Large Business

25% Medium Business

Detailed Reviews of srushty Global Inc

Client Portfolio of srushty Global Inc

Project Industry

- Industrial - 20.0%

- E-commerce - 20.0%

- Information Technology - 20.0%

- Other Industries - 40.0%

Major Industry Focus

Other Industries

Project Cost

- Not Disclosed - 100.0%

Common Project Cost

Not Disclosed

Project Timeline

- 1 to 25 Weeks - 100.0%

Project Timeline

1 to 25 Weeks

Portfolios: 5