mReady

1 Review

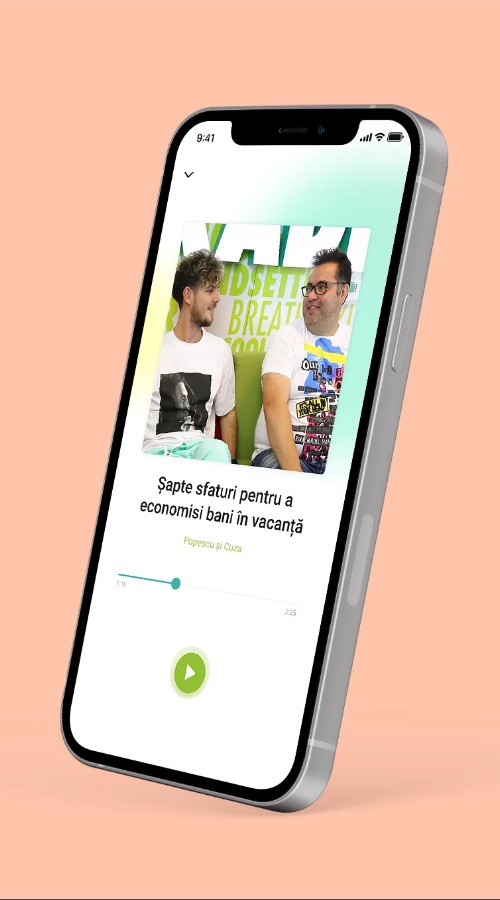

Super App Design & Development

mReady is the place where great mobile apps are being tailored to fit the exciting visions of both startups and companies.

Through our mobile strategy consultancy, design and development services we help our clients reach new horizons in the era of mobile technologies.

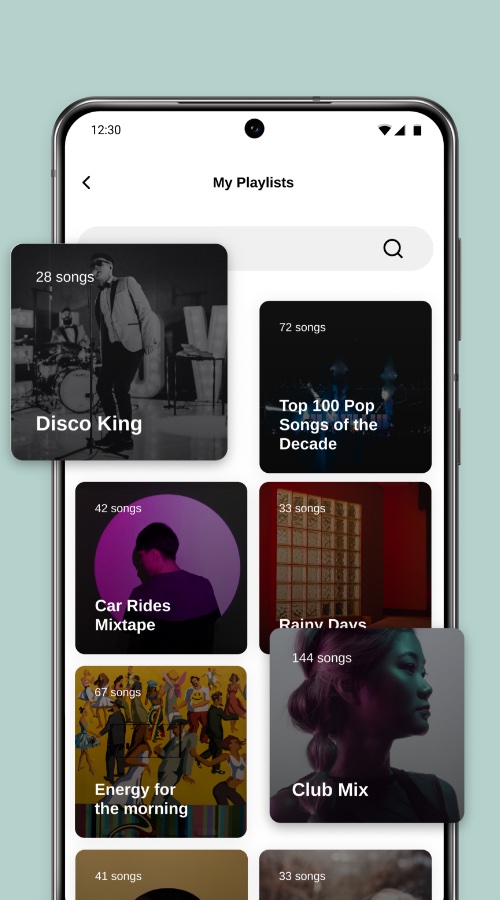

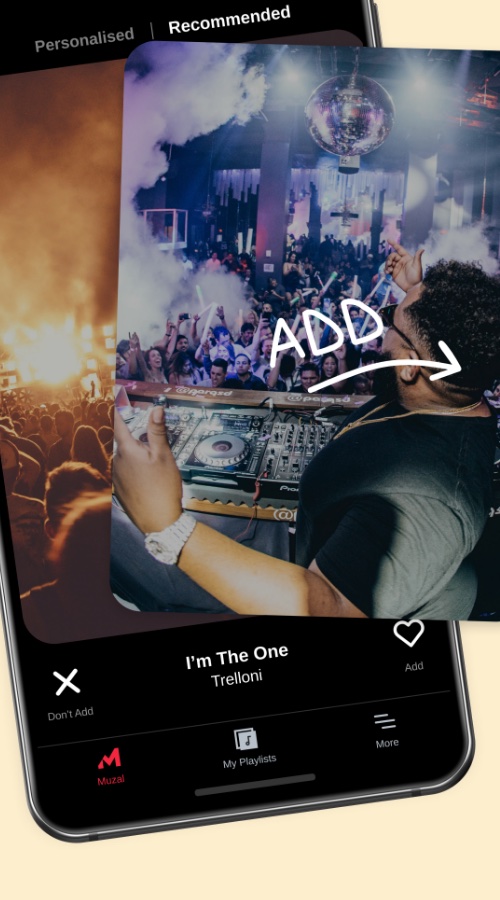

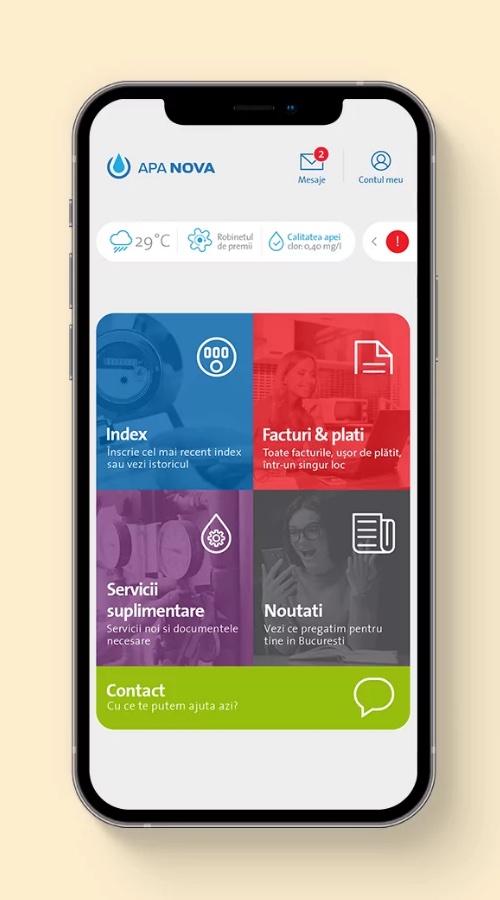

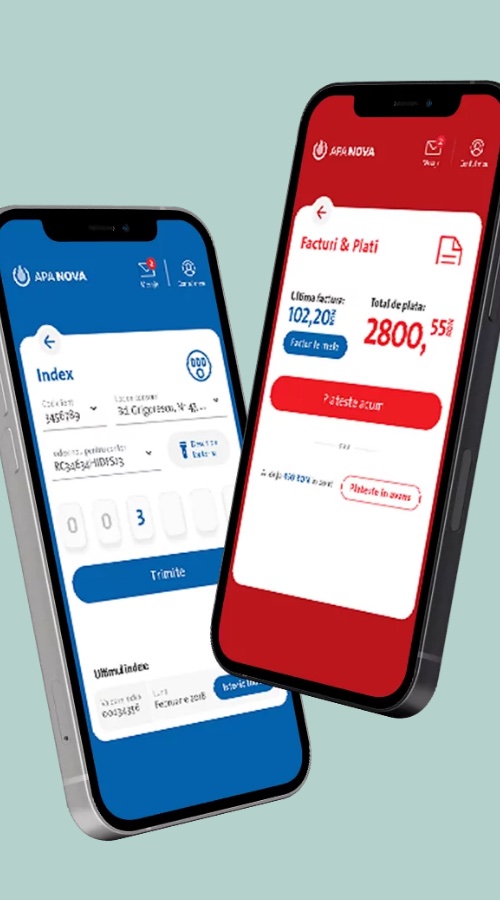

Our portfolio has more than 150 native Android and iOS mobile apps for corporate and startup customers, all around the world. We offer software development, UX design, graphic design and quality assurance.

Through our proven process, tools and resources, what we create is high quality mobile apps that meet the requests of today’s mobile users.

Romania

Romania

8-10, Calea Grivitei, 2nd Floor,

Bucharest,

Bucuresti

010701

+40 758 901 901

$50 - $99/hr

50 - 249

2011

Service Focus

Industry Focus

- Business Services - 20%

- Education - 20%

- Financial & Payments - 20%

- Healthcare & Medical - 20%

- Information Technology - 20%

Client Focus

40% Large Business

35% Medium Business

25% Small Business

Detailed Reviews of mReady

1 Review

- All Services

- Mobile App Development

- Relevance

- Most Recent

- Rating: high to low

- Rating: low to high

Andrei Rosu, President at Asociatia CIA - Coaching In Alergare

Posted on Nov 15, 2018

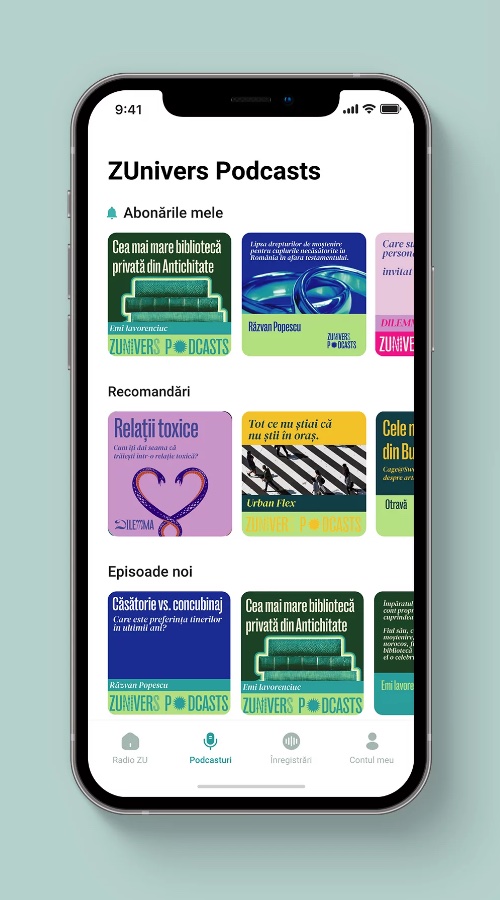

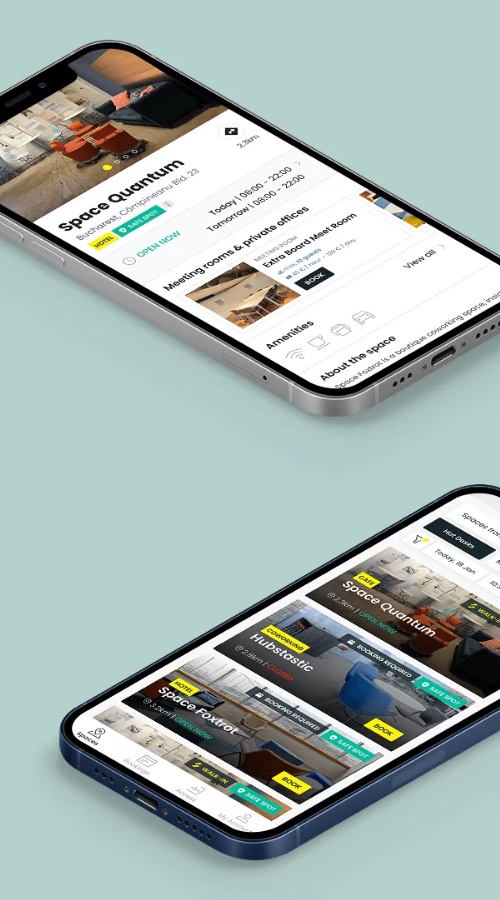

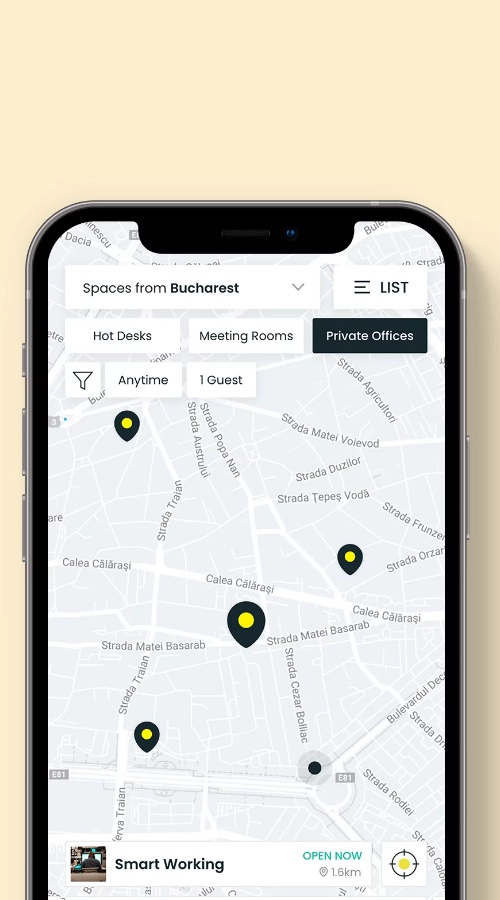

Client Portfolio of mReady

Project Industry

- Media - 28.6%

- Startups - 14.3%

- Art, Entertainment & Music - 14.3%

- Utilities - 28.6%

- NGOs - 14.3%

Major Industry Focus

Media

Project Cost

- Not Disclosed - 100.0%

Common Project Cost

Not Disclosed

Project Timeline

- 1 to 25 Weeks - 57.1%

- 26 to 50 Weeks - 28.6%

- 51 to 100 Weeks - 14.3%

Project Timeline

1 to 25 Weeks

Clients: 6

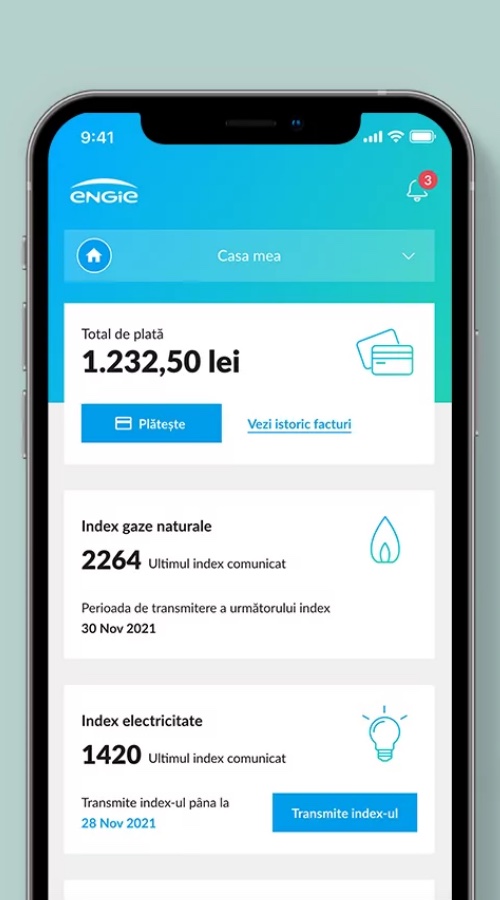

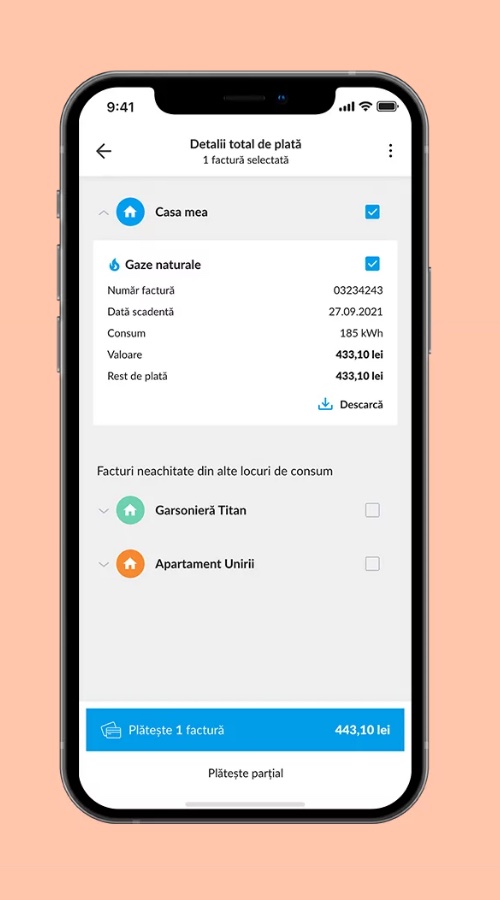

- Engie Romania

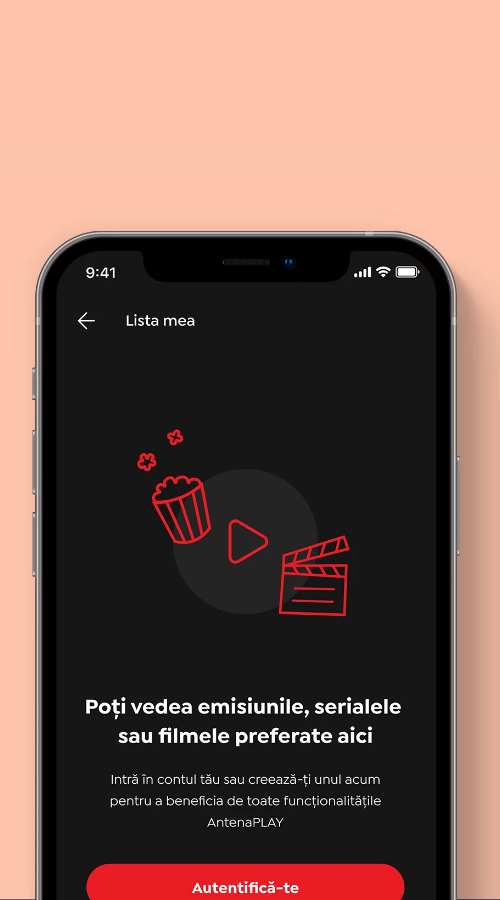

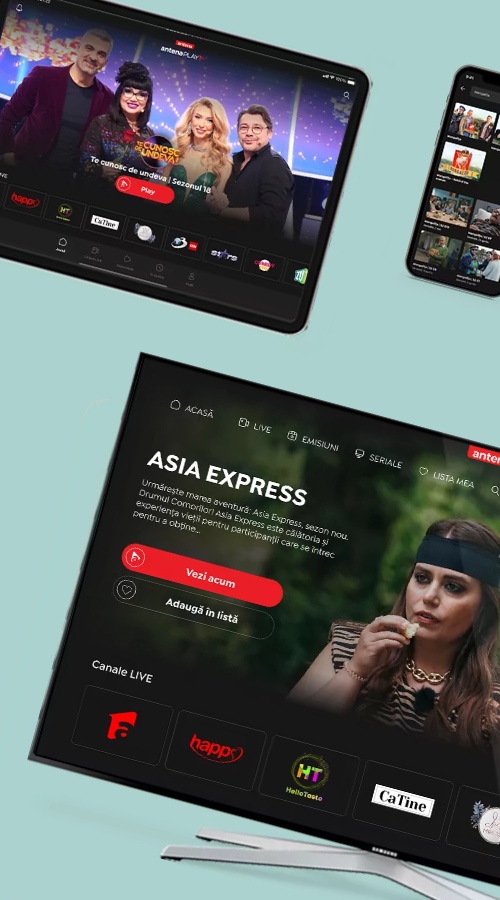

- Antena Group

- Pluria

- Apa Nova Bucuresti

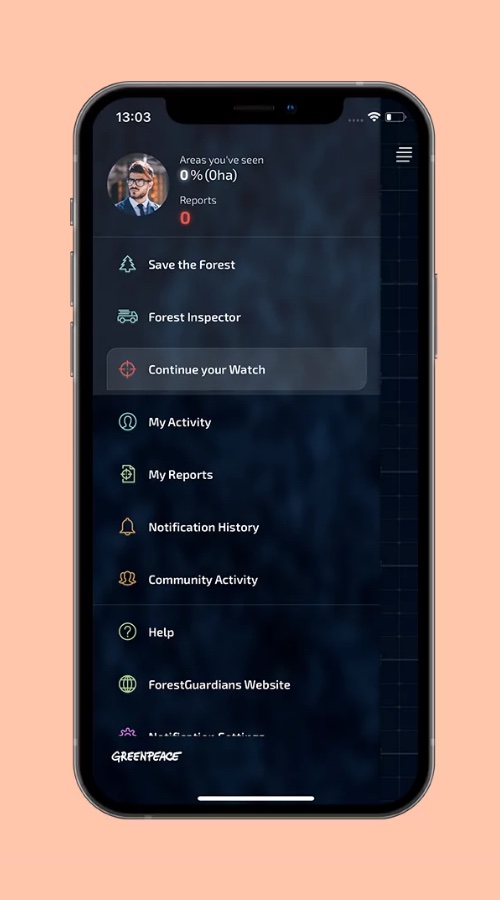

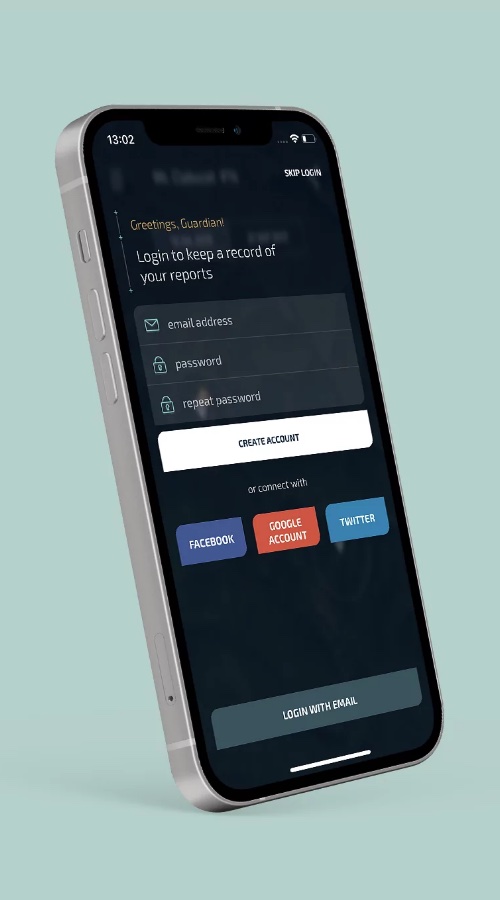

- Greenpeace

- World Wildlife Fund

Portfolios: 7