ABSTRACT:

The packaging industry is on the verge of the biggest transformation it has ever seen. The traditional packaging method focuses on product safety, breakage minimization, and waste reduction. This is now expanding to incorporate a more strategic approach to expanding the organizations' sustainability and digital goals. Packaging designs and materials used in packaging impact buying experiences and play a crucial role in marketing products and enhancing product aesthetics. Product packaging design acts as a motivational trigger for purchasing a particular product and sets brands apart amidst competition.

The accelerating packaging product and design innovations, stringent regulations for packaging material and waste disposal, and shifting consumer behavior with concerns towards sustainability and the environment are key trends leading to cutting-edge transformation in the packaging industry. It would be interesting to see how leaders in the packaging industry take advantage of this opportunity and create more innovative, sustainable, and cost-efficient packaging solutions.

GoodFirms ‘Packaging Industry - Current Trends, Future Demands’ survey aims to explore reliable statistics and valuable insights regarding the packaging industry's ongoing trends, challenges, and future demand perspectives. The research study will help the packaging industry in expediting its initiatives with the latest insights and also benefit the consumers, who expect more efficient, compostable, and sustainable packaging options.

Table of Contents:

Introduction

Overview of the Packaging Industry

Market Overview

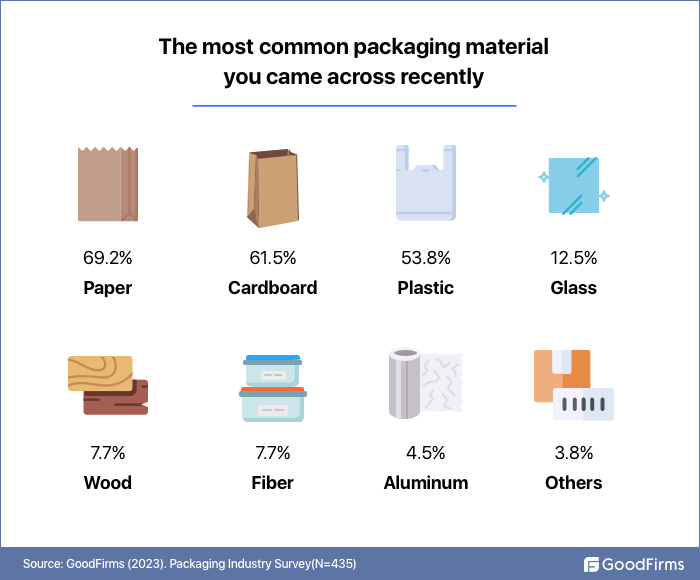

Paper comes up to be the most commonly used packaging material

Factors Impacting the Selection of Packaging Design

Top Trends of the Packaging Industry

- Flexible Packaging

- QR Codes

- Branding through Packaging

- Enhancing the Aesthetics of the Product

- Automation in the industry

- The Emergence of E-commerce

- Product Safety

- Transparency

Challenges Faced by the Packaging Industry

Future of the Packaging Industry

Introduction

The global packaging industry has shown tremendous growth in recent years. It is expected to grow further in the coming years. The packaging sector has been an important supporting factor in the growth of various industries like food, FMCG, and agriculture.

The packaging industry is the backbone of all industries. It plays a vital role in protecting products and ensuring their safe arrival at their destination. The packaging industry has come a long way in the past few years, with the introduction of innovative materials, technologies, and designs that make packaging more efficient and cost-effective. The demand for packaged goods will continue to grow with flexible imports and exports of goods, better management of the movement of goods, demographic growth, and the evolving consumer mindset to purchase products from national and international markets. Packaging also helps companies stand out from the competition and build their brand. From luxury to eco-friendly, packaging plays a key role in how companies present their products and services. By using recyclable materials and better packaging designs, companies can help reduce their environmental impact.

Packaging has become even more crucial with the increasing importance of hygiene and safety. Like all other industries, the packaging industry also shows advancement in technology. With the ever-growing consumer demands for innovations and necessities, the packaging industry has certain demands to meet in the future.

GoodFirms Survey “Packaging Industry - Current Trends and Future Demands” aims to gather insights on the current trends of the industry. The survey also tries to get information about the challenges faced by the industry and analyzes the future demands of the sector.

Overview of the Packaging Industry

Packaging is described as the art and science of storing and protecting products till they are distributed and used. Packaging primarily plays an important role to protect and store goods for logistics and warehousing. While the packaging is a part of various industries, the major user of packaging is the food and beverage industry. The growth of the packaging industry is also the result of the rising trend of eCommerce. Packaging helps maintain quality and lengthen the shelf life of a wide range of products. These products include processed and semi-processed food, drugs, medicines, electrical appliances, domestic appliances, and even industrial machinery.(1)

The demand for increased specialization and sophistication with respect to health and hygiene is one of the major driving factors of the industry. The growing awareness about the hazardous effects of plastic on the human body and environment has made people opt for more natural packaging materials. The pandemic period has shown the importance of hygiene and packaging plays a crucial role in maintaining the hygiene of food products.

Market Overview

The global industrial packaging market has seen exponential growth in recent years. It is expected to continue the growth even in the coming years.

The industrial packaging market, which had a market share of USD 1015 billion in the year 2021, is expected to grow at a CAGR of 3.9% during the forecast period of 2021 to 2026 and reach a value of USD 1.22 trillion.(2)

Asia comes out to be the most significant contributor accounting for 43% of the share, followed by North America, accounting for 23%.

The packaging industry offers applications for a wide range of industries to ensure the safety of goods. The growth of the packaging industry is a result of various factors. These factors include the increase in global wealth, rising e-commerce businesses, and faster growth of the FMCG sector, to name a few.

The ever increasing demand for sustainable packaging options and the emergence of newer technologies like smart packaging use of AI and ML have led to innovations in the packaging industry, leading to its growth.

Survey and Data Analysis

GoodFirms conducted a detailed survey of the packaging industry and queried selected participants regarding their packaging preferences and experiences with packaging companies.

Below are the survey results and findings:

Paper comes up to be the most commonly used packaging material

69.2% of surveyees came across ‘Paper’ packaging recently

Paper is one of the most popular choices used in packaging. Paper-based packing comes in various forms ranging from paper bags to tissue papers and even paper labels.

Paper packaging is a convenient option for carrying delicate items, wrapping food products, and mailing stationery. It is also a product that can be simple to design and easily customizable.

Paperboard

A thicker version of paper that is more sturdy is a paperboard. Paperboard is a primary packaging option that can be customized with respect to its thickness. It is a more durable packaging option when transporting goods.

Tetra packs are one example of paperboards that can help in packaging foods like juices and milk. Thin paperboards are more useful for storing point-of-sale materials, while thicker paperboards are more useful for products that are heavier that need cushioning due to their fragile nature.(3)

61.5% of survey participants have recently seen a product with ‘Cardboard’ packaging

Cardboard is a very versatile material for packaging. Using cardboard for packaging greatly ensures that the product packed will not be damaged. It can be molded into multiple shapes to suit the products.

Moreover, cardboard packaging is a great way to make it a medium of branding. Since cardboard is lightweight, it can assist in cost-cutting during transportation. Another benefit of cardboard packaging is that it is recyclable and easy to dispose of. Being recyclable and lightweight makes cardboard packaging a cost-effective option.(4)

‘Plastic’ is the primary packaging material that 53.8% of survey participants encountered

Plastic has become one of the most popular choices in packaging materials. Plastic containers can be produced at a fast pace and low prices, which makes them readily available.

The versatility that plastic provides suitable for several requirements is another reason why plastics are an industry favorite. However, plastics are not readily recyclable and pose a threat to wildlife. Also, plastic is non-biodegradable and stays on the earth for a long time which becomes a reason for polluting the environment.

Despite the drawbacks of plastic packaging, the low cost and easy availability of plastic make it a popular choice in the industry.

12.5% of survey participants said they recently came across ‘Glass’ as a packaging material

Glass is mostly used in the form of jars or bottles for packaging products. The most common use of glass jars is to store liquids. The fact that glass is inert to most chemicals makes it a better choice for storing foods for a longer period that is at risk of contamination when exposed to oxygen or moisture.

Glass gives a sophisticated look when it comes to storing some high-quality products. Glass packaging can improve the value of the product. Glass packaging is also beneficial as it is recyclable and can be reused multiple times.

The highest share of the market for glass packaging comes from alcoholic and non-alcoholic drinks.(5)

7.7% of survey participants said they encountered ‘Wood’ as a packaging material recently

When it comes to efficient and flexible packaging, wood is an excellent option. These packaging materials are made of either hardwood or softwood based on the products to be packed.

Wood packaging can be done in the form of pallets, crates, and boxes that are mostly used for logistics and shipping. Wooden crates and boxes are suitable for packing bulky products.

7.7% of survey participants have come across ‘Fiber’ as a packaging material recently

Fiber-based packaging materials derived from natural fibers are obtained from growing plants like trees, wheat, and sugarcane. These fibers are mainly produced from renewable resources.

Since the fibers are completely biodegradable, they are the most efficient sustainable packaging options. With the recyclable properties of fibers, they are eco-friendly and can be recycled multiple times.(6)

Packaging materials made from natural fibers are a little expensive which boosts the use of synthetic fibers to produce packaging materials. Packaging material that is derived from synthetic fibers is a good option for custom packaging. Synthetic fibers like polyester are used to make bags or kits which are more durable and resistant compared to the ones made from natural fiber. However, these fibers are non-biodegradable and hamper the environment.

4.5% of surveyees came across ‘Aluminum’ as a packaging material

Aluminum is a versatile packaging material. It can be molded to match the requirements with respect to the shape and thickness of the container. Aluminum can also be recycled, which makes it a better choice.

Aluminum cans and aluminum foils are the majorly used packaging material in the food packaging sector. Aluminum can protect the food and beverages stored and efficiently retain their taste which makes it a good choice.(7)

Factors Impacting the Selection of Packaging Design

Product

76.9% of survey participants believe that the product influences the selection of packaging materials.

The product serves as the most considered factor while selecting the packaging material. Since the protection of the packaged product is the basic functionality of packaging, businesses must think about the nature of their product.

Different packaging materials are meant for different products. While cardboard or paper packaging is suitable for most products, it is necessary to consider factors like the nature of the product, its shelf life, and the impact of climate conditions on the product, to mention a few.

Customer

Customer is a prime factor while selecting a packaging material for 46.2% of survey participants.

Customers are the most crucial part of a supply chain. Businesses must keep in mind their target audience while selecting the packaging material. One of the major factors that have led to the rise of the packaging industry is the rise of global wealth and the organized retail sector.(8)

Packaging design that addresses the customer's needs makes it more effective. Brands must try to work on the aesthetics of the packaging to make it more attractive for the customers.

Materials

38.5% of surveyees believe that materials play an important role in determining the packaging design.

Materials are an important part of packaging design. It is necessary to think if the packaged product reacts chemically with the packaging materials.

Moreover, if the packaged products are food, businesses must ensure that it does not come in contact with moisture and oxygen that will result in spoiling the packaged product.

The packaging design must assure that fragile products reach their destination without any damage. The selection of the packaging material also depends on the state of the product.

Shipping Time and Cost

Shipping time and cost are prime factors for 28.5% of surveyees to select packaging design.

With the advent of e-commerce, packaging designs need to consider certain factors that are required to deliver goods to consumers.

Shipping time and shipping costs play a crucial role in e-commerce businesses. The packaging material used must be capable enough to protect the packaged goods for a long time. The weight of the goods, including the packaging, adds to the shipping costs, and that plays a major role in the pricing of the goods.

Display Area

7.7% of the surveyees say that the display area of the product influences the selection of packaging material.

The display area of the product makes a difference in selecting the packaging design. The aesthetic appearance of the product must be designed according to the area where the product is to be displayed.

Packaging has always been an efficient packaging tool and businesses have always tried to leverage the benefits of this fact. Keeping the display area of the packaged product can assist in selecting the packaging design.

Top Trends of the Packaging Industry

The packaging industry has seen tremendous growth and is predicted to grow further. The growth of this industry is a result of certain trends. GoodFirms’ “Packaging Industry: Current Trends and Future Demands” survey gathers insights about the top trends of the packaging industry.

Flexible Packaging is a top trend in the packaging industry

The product packaging that uses non-rigid, flexible packaging materials, which are generally made of paper and plastic, is called flexible packaging.

Flexible packaging is characterized by the ability to readily change shape based on the product to be packed. They have a wide range of applications due to the flexibility offered. This packaging is generally engineered using a combination of plastic, film, paper, and aluminum foil.

Flexible packaging being lightweight is beneficial in many ways and also convenient to carry and seal. They are a great option to reduce wastage and make the choice sustainable.

Flexible packaging made with a certain combination of materials offers air-tight properties which ensure the higher shelf life of the packaged product, especially food products.

Gerrid Smith, Director of E-commerce Operations at Joy Organics says, “In my perspective, the most important trend in the packaging industry right now is the creation of more flexible packaging. This growing interest in flexible packaging is well-founded. More and more consumer goods, which previously could only be packaged in rigid or hard materials, are now amenable to flexible packaging because of technological advancements.”

Flexible Packaging is a top trend in the packaging industry. The global flexible packaging market was valued at USD 68.5 billion in 2021 and is expected to grow at a CAGR of 4.2% and reach USD 102.8 billion by 2031.(9)

QR Codes

QR codes have seen tremendous popularity in recent years, especially after the pandemic period. The growth in the usage of QR codes was around 94% from 2018 to 2020. (10)

QR codes, also known as Quick Response codes, are special type barcodes that carry immense information which can be accessed by special software. Scanning QR codes is a simple process using a smartphone.

Providing a QR code on product packaging can offer many benefits to businesses. They can help businesses provide all the necessary information for the consumers about the package which can be sometimes difficult to display on small packets. These codes can carry details of the ingredients of the product, nutritional value, and shelf life of the products packed. (11)

Branding through Packaging

Irrespective of the fact that branding and packaging belong to different disciplines, they both are closely related to each other. Packaging design can be a medium to motivate customers to recognize their brand.

Using the brand logo on the packaging is a common practice accepted across industries. The advent of technologies like digital printing is of great aid in making the packaging design customized. Customizing the packaging design with colors or fonts that can be associated with a brand can be of great help in creating a loyal customer base.(12)

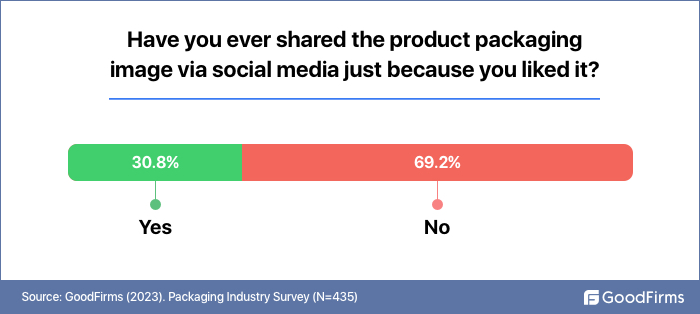

The survey by GoodFirms’ reveals that nearly 30.8% of consumers shared a product packaging image on social media just because they liked the packaging.

A great packaging design can work as a marketing channel for the business. In a world where social media usage has become an integral part of people’s lives, the promotion of a brand through its packaging is a good way to brand.

Enhancing the Aesthetics of the Product

Along with the basic functionality of storing and protecting the packaged product, packaging also plays a crucial role in improving the aesthetic value of the product.

Attractive packaging can make a difference when it comes to selecting the same product from two different brands. Jamie Penney, Owner of My Home Dwelling says, “While it's not necessary for packaging to be the loudest thing on the shelf, it should be memorable by clearly conveying the product's USP. Forms, hues, orientations, and textures all have essential functions. Brands that take pleasure in their subtle or beautiful packaging nonetheless strive to stand out from the crowd by making their designs distinct from the competition.”

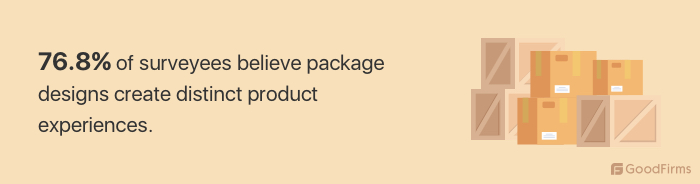

Around 76.8% of Goodfirms’ survey participants are of the opinion that package designs create distinct product experiences.

Packaging aesthetics is an essential aspect that compels consumers to select a particular product and pay extra for buying the product. Packaging aesthetics comprise multiple components ranging from the color, material, texture, and shape of the package. The advances in the field of printing and finishing techniques have led to the rise in complexity and quality of the color schemes and aesthetic appeals of the packaging containers.

Certain geometrical shapes and textures of the containers add to the appearance of the product and grab the attention of the consumers.(13)

Automation in the industry

The fourth Industrial revolution focuses on the personalization of products and services for customers. Emerging technologies like machine learning and artificial intelligence are making a crucial difference in almost all industries, and it is the same for the packaging industry as well.

The smart packaging system uses embedded sensor technologies to make the industry automated. Smart technologies in packaging industries are a great invention for majorly the food and pharmaceutical industry. It can play a crucial role in monitoring the freshness and quality of packaged products. It also assists in increasing the shelf life and improving product and customer safety.

The global smart packaging market is expected to grow to USD 26.7 Billion by the year 2024.(14)

Jamie Irwin of James and James Fulfillment says, “A significant trend in the packaging sector is the automation of packaging operations such as de-panning, filling, packing, and palletizing.”

The Emergence of E-commerce

The last decade has seen a surge in E-commerce. The rise of e-commerce has been even more after the pandemic. This tremendous increase in the use of online shopping has led to a rise in packaging demands. Along with the dedicated eCommerce websites, goods are now being sold on social media websites as well. The ever-growing market share of E-commerce is a major factor that is fueling the growth of the packaging industry.

When eCommerce packaging is considered, it becomes necessary to ensure that the product is delivered to the consumer without any damage. The factors considered for this type of packaging differ from the products that are sold in a retail store.

E-commerce packaging has a certain set of guidelines to follow including the limitation on the weight of the package, material of packaging used, proper sealing of the package, size and weight of the product to be packed, and placement of the package to keep them safe.(15)

Product Safety

Product packaging becomes an essential part when it comes to the safety of the product. The safety and shelf life of the products, especially food products, are what should be considered while designing a package.

“One trend that is taking place in the industry of packaging, which is much more in focus today than it was a few years ago, is the safety of products, particularly food. This topic encompasses a wide range of topics, including migration in order to save food, product piracy, and counterfeit product protection,” says Jamie Penny, CEO of Shopping Foodie.

With the increased concerns about safety and hygiene during the pandemic period, it has become even more important for the packaging industry to work on improving product safety. The rise in the consumption of packaged food and online food services is the reason for the promotion of packaging material that meets the requirement of keeping the contents safe.

Packaging of delicate products, perishable foods, etc., requires the selection of packaging material that will prevent damage to the packaged products. It is also necessary for businesses to consider safeguarding children under the age of 5 when the packaged products are supplements, drugs, cosmetics, or any other chemical products.(16)

Transparency in Labeling

Honesty and transparency are the fastest-growing trends in the packaging industry. The packaging must be characterized with proper details of the packaged product.

Benjamin Stenson, CEO of Norsemen Home Remodelling says, “There is a current trend toward more transparent and honest labeling. This implies that consumers may easily get information about the product's ingredients, nutritional value, and environmental friendliness by reading the label. Whether or if your packaging is biodegradable or recyclable, that fact should be communicated in the visuals. It should be made obvious if the goods are low-sugar, organic, or made from plant-based ingredients.”

The information on the ingredients of the packaged products is of great importance for foodstuffs, pharmaceuticals, and even cosmetic products. In times when consumers are more interested in buying products that are all-natural, honesty from brands can make a difference in creating trust among consumers. Transparent packaging with accurate labeling enables consumers to see through and make a decision about purchasing the products.

Challenges Faced by the Packaging Industry

Cost of raw materials

The market conditions in recent years have led to the rise of raw material costs for several industries, and the packaging industry is one of them.

Oil prices have seen a rise of around 58% since November 2020. Also, the shortage of global shipping containers is a major reason for the raw materials price increase. The scarcity of the raw materials supply, including metals and polymers, is a major reason for the sharp spike in their prices.(17)

Furthermore, the emergence of E-commerce has resulted in high demand for corrugated cardboard. The rise in the demand for corrugated boxes also means the rise in demand for paper and other raw materials required for packaging products that are supplied through e-commerce channels. All this cumulatively results in the rise of raw material costs for packaging products. (18)

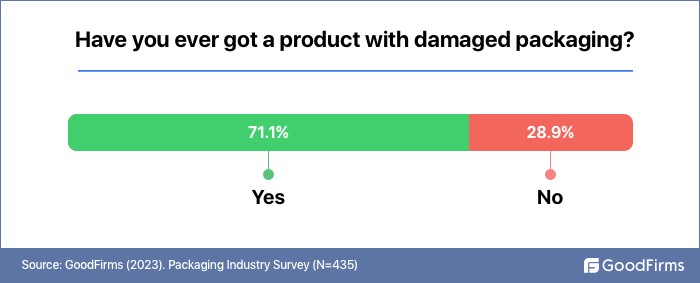

Protection of the Packaged Products

One of the basic functionalities of packaging is to protect the product packed. It is expected that a packaging design must be capable of preventing the packaged product from any kind of deterioration. However, the survey by GoodFirms about the packaging industry reveals that around 71.1% of survey participants have received a product with damaged packaging.

Extended transport routes, harsh weather, mishandling by poorly trained employees, inadequate packaging, low-quality packaging materials, etc, are reasons for the supply of damaged products to the end users. While luxury and delicate products are at a high risk of physical damage, foodstuffs that are in transit for a long time are also at risk of being spoiled.

Damaged goods received at the user end leads to monetary loss and customer dissatisfaction which can adversely affect the brand's reputation.

With the rise in the use of e-commerce channels and packaged food, it has become necessary to think of ways to reduce the possibility of damage to packaged goods and the long shelf life of foodstuff and pharmaceuticals. (19)

Packaging Waste

Plastic is one of the major packaging materials. Being cheap and readily available, single-use plastic is widely used for packaging most products.

Along with plastic, there are some packaging materials that are not easily biodegradable. It is estimated that plastic and other packaging waste make up around 30% of the total US waste annually. (20)

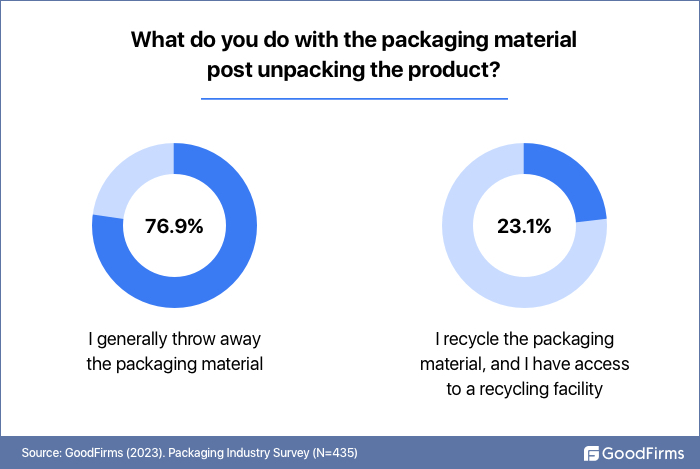

The lack of recycling facilities for plastic waste makes it even more difficult to minimize waste. Around 76.9% of the GoodFirms’ survey respondents assert that they throw away the packaging material, the major reason being non-accessibility to a recycling facility.

The use of single-use plastics can pose a threat to the environment. The use of biodegradable packaging material must be promoted to reduce the strain on the waste management system. It has become even more crucial due to the growing awareness of environmental problems.

Food packaging and Food Waste

The rise in the demand for ready-to-use food products has given rise to an increase in food and associated packaging wastage. This kind of food packaging generally consists of single-use plastic packaging. Food and plastic packaging waste is a reason for greenhouse gas emissions.

The packaging industry has thus come up with the concept of no-waste packaging (zero-waste packaging) which uses packaging materials that are totally reusable or recyclable. A few examples of no-waste packaging are the use of returnable glass bottles for milk or carrying containers for grocery shopping or even edible packaging.

Changing Customer Behaviour Patterns

Consumer behavior study is a crucial process to identify consumer requirements. With the changing environmental and health conditions, consumers are more conscious than ever before about the products they use.

Consumers are the heart of a business. Consumer behaviors and demands are the most important part that needs to be considered while designing product packaging.

Customer satisfaction is the key to retaining a customer base for the company, and packaging plays an important role. Keeping an eye on changing consumer behavior and demands is significant in designing the packaging of any product.(21)

Sustainability

With the growing awareness about the harmful effects of certain packaging materials on the environment, there is an ever-increasing demand for sustainable packaging options.

Even government bodies are working towards strengthening the regulatory norms against the use of packaging materials like single-use plastic. The recyclability of packaging material is a crucial factor that makes a packaging product sustainable.

The demand for sustainable packaging options is a challenge for the industry due to the lack of available options. (22)

“Companies that invest in sustainable packaging will likely see a decrease in their profit margin as a result of the higher production cost. Until sustainable packaging is more widely accessible and financially viable for the packaging industry, this may slow its expansion in the years ahead.” says Travis Lindemoen, Managing Director of Nexus IT Group.

Future Demand Factors of the Packaging Industry

The packaging industry has seen tremendous growth in the last few years. The industry is expected to grow further in the coming years as well.

Sustainable Packaging Material will be in Demand

With the growing concerns of changing environmental conditions and global warming, the demand for newer sustainable packaging materials will equally grow.

Sustainable packaging options have gained importance in recent years and sustainable choices will be significant in the coming years too. The encouragement from governments and environmentalists is also a reason for choosing more sustainable materials. Moreover, consumers are also in favor of environmentally friendly and sustainable packaging.

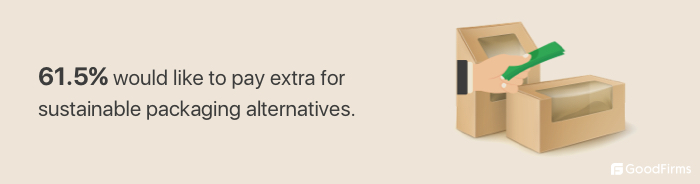

61.5% of the Goodfirms’ survey participants would readily pay extra for sustainable packaging alternatives.

The future of sustainable packaging will see multiple packaging options that will be eco-friendly and have a positive impact on the environment. The use of plant-based material for packaging is one of them.

The emergence of edible packaging is another interesting trend to look out for. The trend of edible packaging has been in existence for a while. However, it is getting more popular now, majorly in the food industry. Edible packaging is a new option for waste that is created with the use of wrappers, straws, bottles, cutlery, etc. Edible packaging can surely be a great substitute for the use of plastic, as they are biodegradable and can be easily disposed of even if consumers do not opt to eat the packaging.

The main sources of edible packaging can be seaweed, potato starch, and milk proteins.(23)

One more trend that can see growth is the use of fabrics like jute or some textured cloth piece for wrapping instead of plastics or wrapping papers that can even help improve the aesthetic value of the package.

Plastic packaging is the most versatile option. However, due to its hazardous effects on nature, the use of plastic has become a huge problem. The use of bioplastic has emerged as an alternative to plastic packaging. Bioplastics, mostly plant-based, exhibit better biodegradable properties. Although the adoption of bioplastics is slow in the industry, they have a bright future in the packaging industry.

The market share of the bioplastics packaging market is estimated at USD 10.5 billion in the year 2022 and is expected to grow to USD 16.6 billion by 2027 at a CAGR of 9.5%.(24)

Applications of AI and ML will Make the Packaging Processes More Efficient

Technologies like Artificial Intelligence and Machine Learning are coming to the aid of almost all industries. There is a vast range of industry-specific applications for these technologies. Similarly, these technologies have made a difference in the packaging industry as well.

The application of AI, ML, and other similar technologies will help make the functioning of the packaging industry even smoother and more efficient. Automating the fulfillment process can help businesses save both time and money.

Implementation of AI in the packaging process of a product is a great way to assess the final product being packed. The installation of AI-powered cameras is being adopted by several businesses, and it has helped them detect if some assembly parts of the product are missing. Such applications can help businesses cut down on shipping costs by avoiding the shipment of defective products.

Assessing the products is also crucial for e-commerce companies. Proper utilization of automation technology can also assist in selecting the proper packaging design for products. The giant e-commerce company Amazon has reduced the damage rate by 24% with the use of an AI-enabled algorithm to choose the right packaging type based on the product.(25)

Technologies like ML work on the accumulation of data and its analysis. The implementation of such technologies plays a crucial role in data labeling. The availability of accurate data will help in the proper labeling of products which assists in standardizing procedures in order to satisfy customers.

Employing robotics in the packaging industry can be immensely beneficial. It can play a crucial role in reducing packaging waste. Robotics is a great way to create sustainable packaging options. It can help tremendously in reducing the cycle time of the fulfillment process, which can, in turn, help reduce costs.

AI can also help in automating packaging processes like de-panning, filling, packing, and palletizing.(26)

Smart Packaging Solutions will Differentiate Brands

Smart packaging technology is the packaging system that is embedded with sensor technology. Smart packaging is a great aid to improving product quality and maintaining the same through digitization and offers future opportunities for the development of Industry 4.0.

Smart packaging is responsible for monitoring the changes in the packaged product and acting accordingly. While smart packaging has been used in food packaging for some time now and has much more to offer.

Smart packaging works on components placed in the packages that monitor the movement of the package and also the effect of temperature changes on the product packaging. It helps retailers be aware of the condition of their product when it reaches the customer. It plays a crucial part in providing a product in good condition to the consumer. This can help in gaining customer trust. It can also aid the customer in knowing the location of the package.

The integration of intelligent packaging can help maintain the condition of the product by acting appropriately and improving the shelf life of the product. It can help the food and pharma industry to a great extent, where weather conditions play a vital role in maintaining the quality of the products. Real-time access to accurate information is of key importance for the industry.(27)

Packaging Customizations will be Must to Lure Customers

Packaging for a product is the first impression that is created on the consumer. A custom package is a great way to attract the attention of consumers that are approaching a brand for the first time.

Just a corrugated cardboard box with the logo of a brand does not account for customization packaging. With the emerging competition among multiple brands, it is a compulsion for businesses to be unique in every aspect, and packaging is one of them. The fact that packaging is a crucial driver of a company’s revenue can be seen in the GoodFirms survey.

Around 54.5% of surveyed consumers affirmed that the sight of packaging made them make a snap decision to pick a certain product.

Customized packages are currently in trend, and it is here to stay for a longer time. Custom packaging creates a reputation for a brand and makes them stand out from the crowd. Customization in packaging includes a wide range of factors that can make a difference, including packaging material, the shape of the package, and the color scheme used.

An emerging trend that is expected to grow in the future is the customization of boxes with respect to customers. Having a scope to personalize the package for consumers is the customization that brands are working towards.

The custom packaging box market, which accounted for USD 5.7 billion in the year 2022, is expected to grow at a CAGR of 4.7% and reach a value of USD 9.0 billion in the year 2032.(28)

Use of sensor technology is also a part of customizations in the food-packaging industry. Implementation of a color-changing label after reacting with the packaged product when it deteriorates can help in avoiding food wastage.(29)

An Era of Digital Printing

Labels add a distinct meaning to a packaging design. Printing labels on packages comes with a series of challenges like accuracy, low color quality, and appropriate fonts to name a few.

92.3% of the surveyees believe that the color, shape, and font of the label on packaging matter to them.

Labeling which was once a non-flexible element of the packaging industry leading to creating a limitation for personalizing the packaging experience. However, digital printing has come to the assistance of the packaging industry.

The emergence of digital printing has provided the packaging industry with quick and innovative solutions for a wide range of labels. With the increasing inclination towards personalized packaging designs, digital printing has a scope to grow and become an integral part of the packaging industry.

The global digital printing packaging market which was USD 19.45 billion in the year 2021 is expected to grow at a CAGR of 8.30% and reach USD 31.94 billion in the year 2027.(30)

Key Findings

- The Packaging Industry is an ever-growing industry and offers to be a supporting factor for several industries.

- Packaging works towards protecting and storing products.

- Paper, Cardboard, Plastic, Wood, Aluminium, and Fabric are the major packaging materials used across several industries.

- The industrial packaging market accounted for USD 1015 billion in the year 2021 and is predicted to grow at a CAGR of 3.9% to reach USD 1.22 trillion by the year 2026.

- Paper is the most commonly used packaging material, as affirmed by 69.2% of the surveyees.

- Cardboard is the second most commonly used packaging material as noticed by 61.5% of surveyees followed by plastic.

- Selection of a packaging design depends on various factors like the product packaged, shipping time and cost, customer, material, and display area.

- Flexible packaging is a non-rigid packaging type that readily changes shape and is a growing trend due to the benefits it offers.

- Flexible packaging can help in increasing the shelf life of food products.

- QR codes or Quick Response codes are widely being used since they can store immense amounts of information and give quick access to consumers.

- The emergence of E-commerce is a major driving factor for the packaging industry.

- Packaging design must be equipped with maintaining product safety which has become important to consumers more than ever before.

- Increasing cost of raw materials is a major concern for the packaging industry.

- Packaging waste is challenging for packaging businesses due to the adverse effects it has on the environment.

- Changing customer behaviors pose challenges to the packaging industry.

- 61.5% of the survey respondents say that they would pay extra for sustainable packaging alternatives.

- Use of technologies like artificial intelligence and machine learning is the future of the packaging industry.

- Customized packaging is an emerging trend in the packaging industry.

Conclusion

Packaging industry has a humongous market share. The industry has seen tremendous growth in the last few years and it will continue to grow exponentially henceforth.

The increased significance of packaging that came to light due to the importance of hygiene and safety made the industry work harder. The use of packaging for storing and protecting goods during transportation in adverse conditions makes the industry an integral part of almost all other manufacturing industries.

Packaging is ubiquitous owing to its presence in all aspects of human life. Being used in industries like food, cosmetics, self-care, electronics, and others it is a part of day-to-day life. The change in consumer behavior, therefore, has a direct impact on the packaging industry.

The modern packaging industry works under the influence of various factors like rising awareness about sustainable packaging options, personalized packaging, and minimalist choices of consumers that have made businesses think of more creative designs. The aesthetic appearance of the package also adds to the value of the product and is, hence, a prime factor to consider while designing.

The emergence of technologies like AI and ML is working towards the automation of the packaging process reducing operating time, cost, and packaging waste. Smart packaging is an essential approach to making the packaging process error-free and cutting shipping costs. It helps keep the goods safe and maintain and assess their quality.

The growth of the packaging industry in the future largely depends on sustainable choices and automation of the process making packaging smarter.

We sincerely thank our Research Partners for their valuable insights.

References

- https://www.nsic.co.in/pdfs/STUDY/techgapstudy.pdf

- https://www.smithers.com/services/market-reports/packaging/the-future-of-global-packaging-to-2026

- https://www.prestonboard.co.uk/2018/07/30/paperboard-package-goods/

- https://ribble-pack.co.uk/blog/cardboard-best-packaging-material

- https://books.google.co.in/books?hl=en&lr=&id=H9pkAgAAQBAJ&oi=fnd&pg=PP1&dq=types+of+packaging+materials&ots=IDFY5X9eAS&sig=I-1anjUmezn_tKzMfMVz2H7bSwU&redir_esc=y#v=onepage&q&f=false

- https://www.smithers.com/services/market-reports/packaging/the-future-of-fibre-based-packaging-to-2027

- https://www.aluminiumleader.com/application/packaging/#:~:text=Aluminium's%20ability%20to%20form%20any,an%20infinite%20number%20of%20times.

- https://d21buns5ku92am.cloudfront.net/68798/documents/39437-Oaklins-Flexible-Packaging-Spot-On-May2018-abe783.pdf

- https://www.alliedmarketresearch.com/flexible-packaging-market

- https://www.bluebite.com/nfc/qr-code-usage-statistics

- https://www.researchgate.net/publication/359851411_Evaluating_the_Use_of_QR_Codes_on_Food_Products

- https://www.jstage.jst.go.jp/article/jssdj/58/5/58_5_5_11/_pdf/-char/ja

- https://www.linkedin.com/pulse/packaging-aesthetic-appeal-sunil-khopkar

- https://www.sciencedirect.com/science/article/pii/S2212827118304104

- https://www.shiprocket.in/blog/ecommerce-packaging-guidelines/

- https://smallbusiness.chron.com/packaging-safety-requirements-78033.html

- https://www.researchgate.net/publication/350458581_RAW_MATERIAL_PRICES_INCREASE

- https://www.gwp.co.uk/guides/why-packaging-costs-are-rising/

- https://www.packagingstrategies.com/articles/96483-protective-packaging-a-must-in-an-e-commerce-era

- https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/containers-and-packaging-product-specific

- https://www.ijsdr.org/papers/IJSDR1904023.pdf

- https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/the-drive-toward-sustainability-in-packaging-beyond-the-quick-wins

- https://cen.acs.org/food/food-science/time-edible-packaging/98/i4

- https://www.futuremarketinsights.com/reports/bioplastics-packaging-market

- https://arxiv.org/pdf/2006.03239.pdf

- https://datatechvibe.com/ai/is-ai-driving-packaging/

- https://core.ac.uk/download/pdf/159106074.pdf

- https://www.futuremarketinsights.com/reports/custom-packaging-boxes-market

- https://packagingeurope.com/comment/should-we-be-reviling-or-reinventing-food-packaging/8864.article

- https://www.imarcgroup.com/digital-printing-packaging market#:~:text=The%20global%20digital%20printing%20packaging,8.30%25%20during%202022%2D2027.